Composite wave-absorbing material for wave-absorbing shielding film and wave-absorbing shielding film applied thereto

A technology of composite wave-absorbing materials and shielding films, applied in radiation-absorbing coatings, magnetic field/electric field shielding, coatings, etc., can solve the problems of few types of components, difficulties, and dispersion of graphene powder addition, and achieve a wide range of components Less, solve technical problems, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

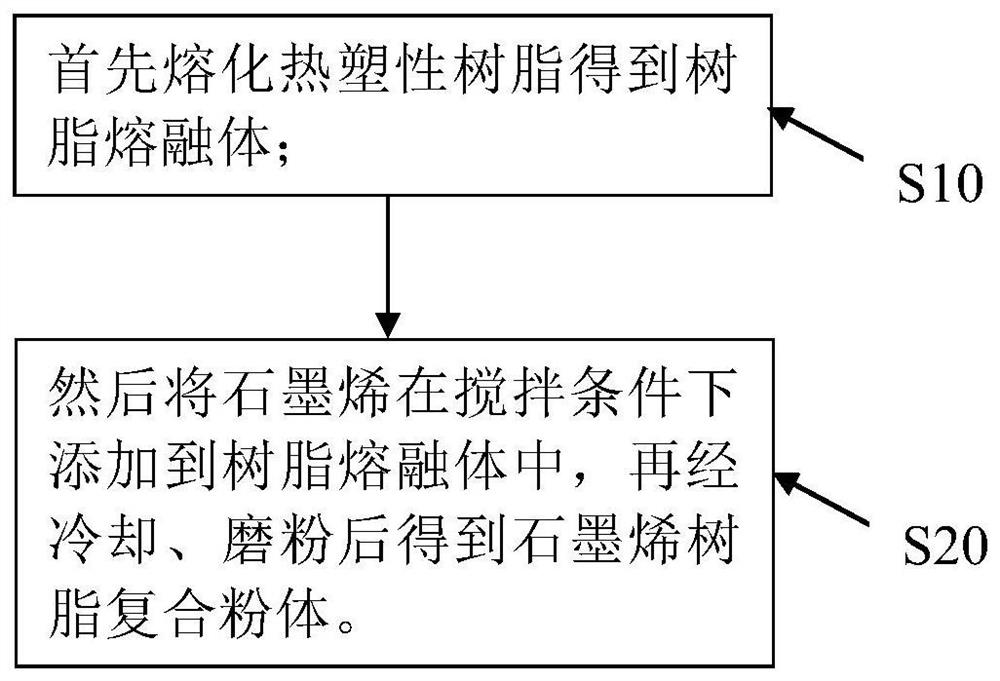

[0030] Preferably, in this embodiment, the graphene resin composite powder includes graphene and a thermoplastic resin, part or all of the surface of the graphene is coated with a thermoplastic resin, and the thermoplastic resin is polypropylene resin; preferably, please refer to figure 1 Shown, the preparation method of graphene resin composite powder comprises the following steps:

[0031] S10), first melting the thermoplastic resin to obtain a resin melt;

[0032] S20), then adding the graphene into the resin melt under stirring condition, and then cooling and pulverizing to obtain the graphene resin composite powder.

[0033] Preferably, in this embodiment, the particle size distribution D50 range of graphene is 1-20 microns; the particle size distribution D50 range of graphene resin composite powder is 25-50 microns; the mass fraction range of graphene is 1-10 parts, the range of parts by mass of the thermoplastic resin is 90-99 parts.

[0034] Preferably, this embodime...

Embodiment 1

[0036] Example 1: A composite wave-absorbing material for a wave-absorbing shielding film, including a wave-absorbing mixed liquid, which is coated on a carrier film layer and cured, and the wave-absorbing mixed liquid includes uniformly mixed wave-absorbing powder And water for configuring the wave-absorbing powder into a wave-absorbing mixed solution, the wave-absorbing powder accounts for 70% of the solvent concentration, wherein the wave-absorbing powder includes the following raw materials in parts by weight:

[0037] 65 parts of carbonyl iron powder;

[0038] 25 parts of graphene resin composite powder; Wherein, the preparation method of graphene resin composite powder comprises the following steps:

[0039] S10), first melting the polypropylene resin to obtain a resin melt;

[0040]S20), then graphene is added in the resin melt under stirring condition, obtain graphene resin composite powder after cooling, pulverizing again, through particle size distribution instrumen...

Embodiment 2

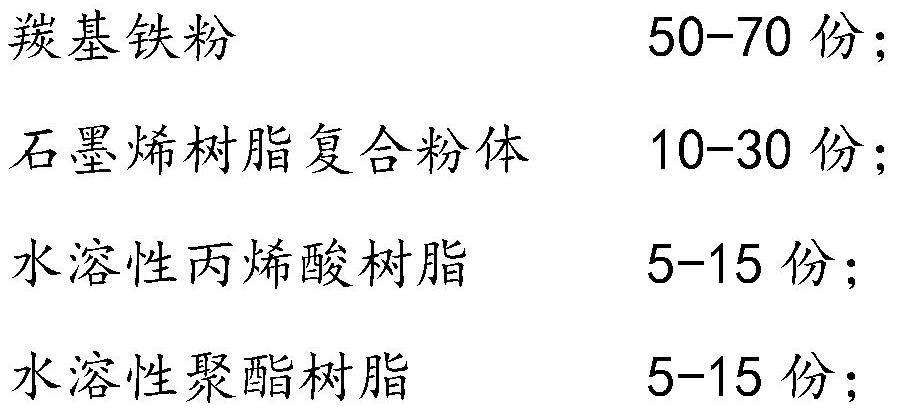

[0044] Embodiment 2: The remaining technical solutions of this embodiment 2 are the same as those of embodiment 1, the difference is that, in this embodiment 2, the wave-absorbing powder includes the following raw materials in parts by weight:

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com