Polyolefin microporous membrane

A microporous membrane, polyolefin technology, applied in structural parts, battery pack parts, electrochemical generators, etc., can solve the problem of undocumented biaxially stretched membrane strain rate, etc., to improve productivity and safety. , The effect of preventing shrinkage and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0233] (A) Using a tumbler blender (tumbler blender), 45 mass % of Mv700,000 high-density polyethylene, 45 mass % of Mv250,000 high-density polyethylene, and 10 mass % of Mv400,000 homopolypropylene were dry-blended to obtain Raw resin mixture. 32% by mass of the raw material resin mixture, 68% by mass of liquid paraffin, and 1% by mass of antioxidant were blended to obtain a polyolefin composition. Next, the polyolefin composition was put into a twin-screw extruder, and the molten polyolefin composition was extruded with a die-lip pitch of 820 μm to form a gel-like sheet, which was cooled and solidified with calender rolls.

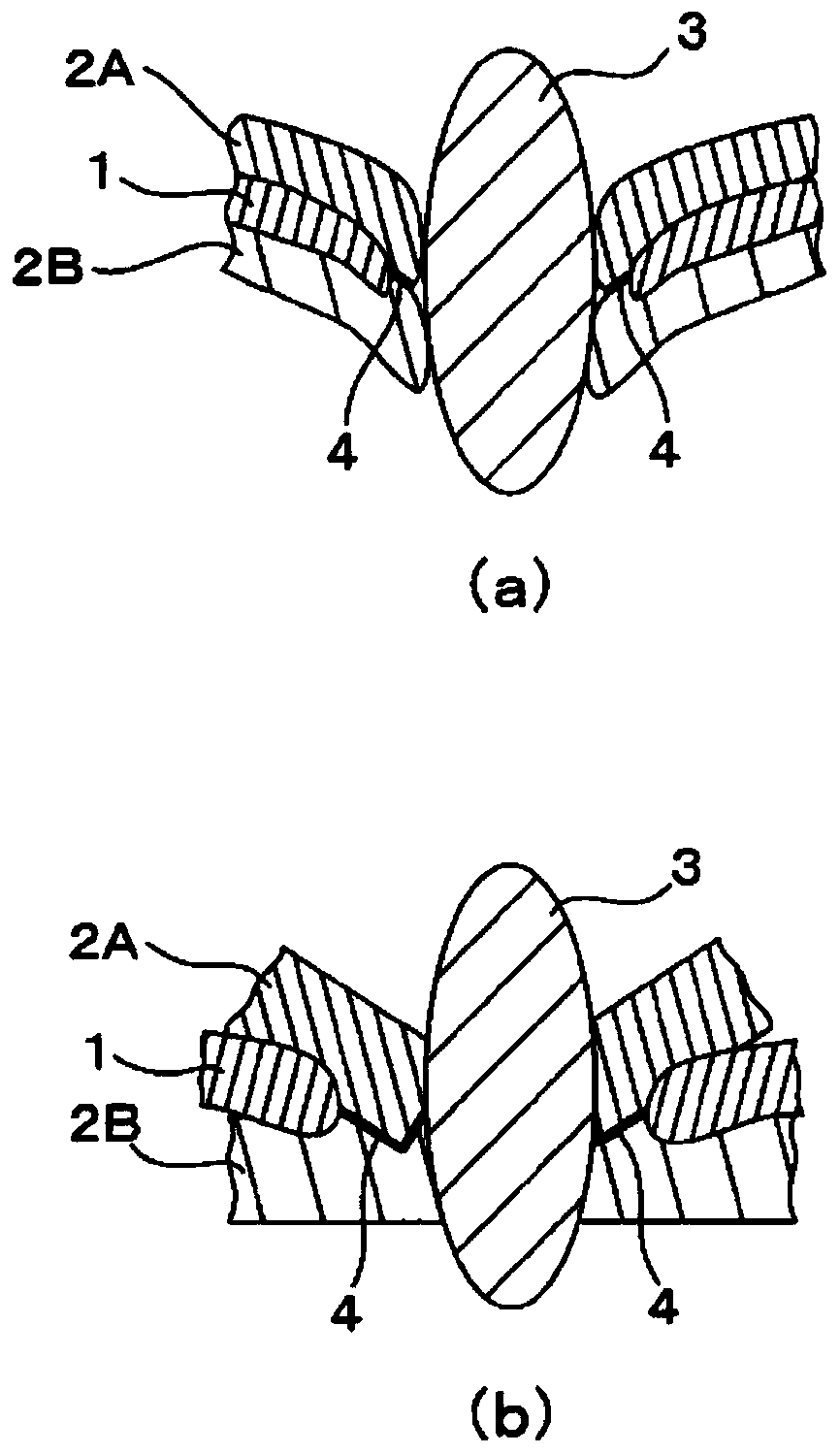

[0234] (B) Using a simultaneous biaxial stretching machine with a set temperature of 122° C., a surface magnification of 49 times (7 times in the longitudinal direction, and 7 times in the width direction), a strain rate of 22% / sec in the longitudinal direction, and a relative The cooled and solidified sheet was stretched at a strain rate in the width d...

Embodiment 2~11 and comparative example 1~9

[0240] A polyolefin microporous membrane was obtained and evaluated in the same manner as in Example 1 except that the production conditions shown in Table 1 were used. The evaluation results are shown in Table 1 below.

Embodiment 12~13

[0242] (A) 25% by mass of Mv2 million polyethylene, 15% by mass of Mv700,000 high-density polyethylene, 30% by mass of Mv250,000 high-density polyethylene, and 30% by mass of Mv150,000 high-density polyethylene using a drum mixer The polyethylene is dry blended to obtain a polyolefin resin mixture. 35% by mass of the raw material resin mixture, 65% by mass of liquid paraffin, and 1% by mass of antioxidant were blended to obtain a polyolefin composition. A polyolefin microporous membrane was obtained and evaluated in the same manner as in Example 1 except that the resin composition obtained in this way was used and the production conditions shown in Table 1 were used. The evaluation results are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com