Beach sand shaking table concentrate high efficiency dehydrating predrying continuous production system and method

A production system and pre-drying technology, applied in drying, dryer, separation methods, etc., can solve the problems of high labor intensity, dust in the workshop, low degree of automation, etc., to reduce production costs and energy consumption, improve Environmental quality, the effect of improving dehydration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

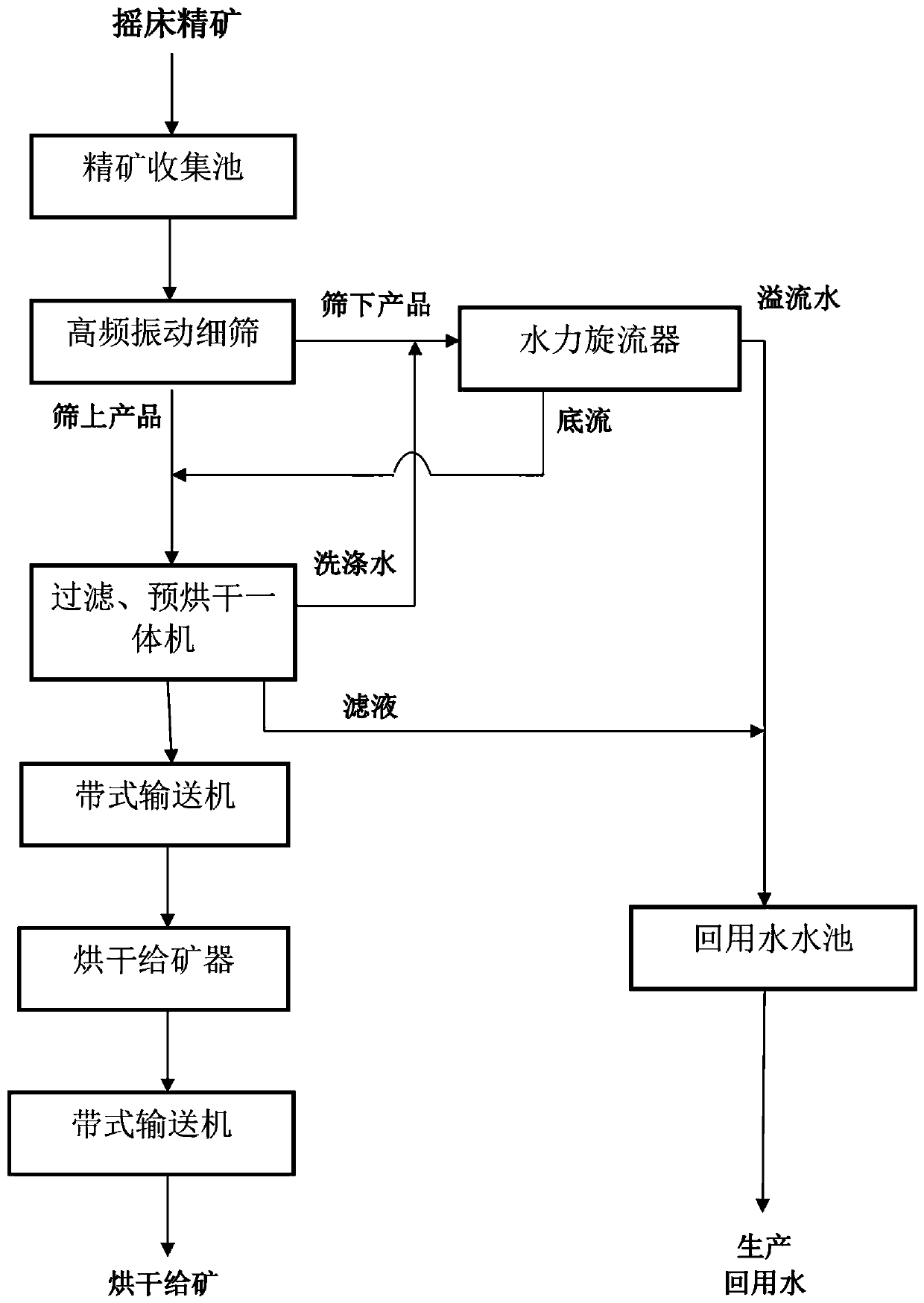

[0026] Such as figure 1 As shown, a seashore sand shaker concentrate efficient dehydration pre-drying continuous production system described in this embodiment includes a concentrate collection pool for collecting shaker concentrate, a high-frequency vibrating screen, and an integrated filter and pre-dryer , Conveyor belt, drying feeder, hydrocyclone, reuse water pool. Wherein, the concentrate collection pool is connected with the high-frequency vibrating screen, and the concentrate collection pool collects the shaker concentrate and feeds it to the high-frequency vibrating screen; the high-frequency vibrating screen is connected with the filtering and pre-drying integrated machine and the hydrocyclone , the discharge end on the screen of the high-frequency vibrating screen is connected with the integrated filter and pre-drying machine, and the discharge end under the screen of the high-frequency vibrating screen is connected with the hydrocyclone. The filter and pre-drying i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com