Powder blender mixer

A mixer and powder technology, applied in mixers, mixers with rotary stirring devices, mixing methods, etc., can solve the problems of uneven mixing of mixed powder materials, affecting the integrity of materials such as natural graphite, etc. The effect of feed capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

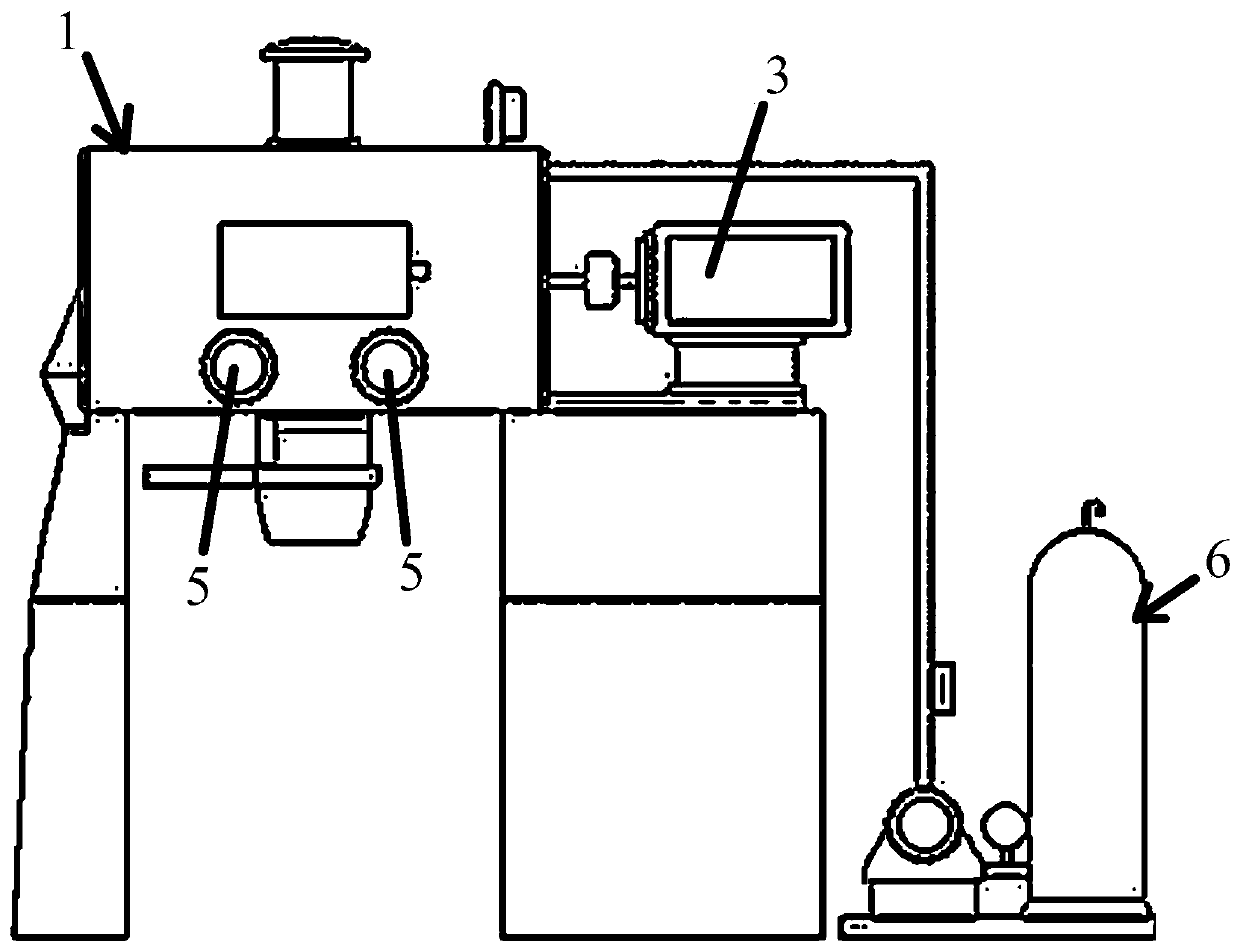

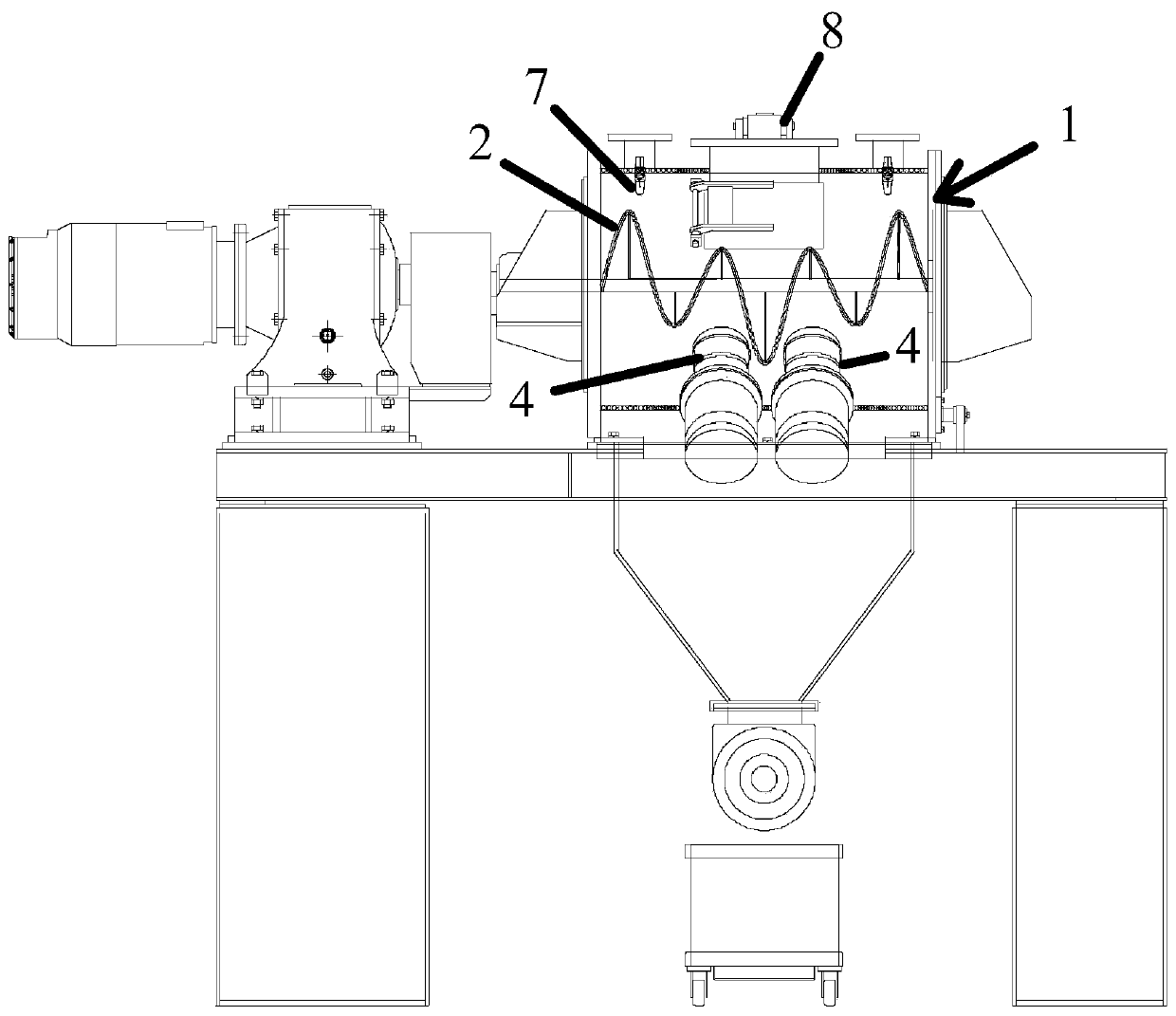

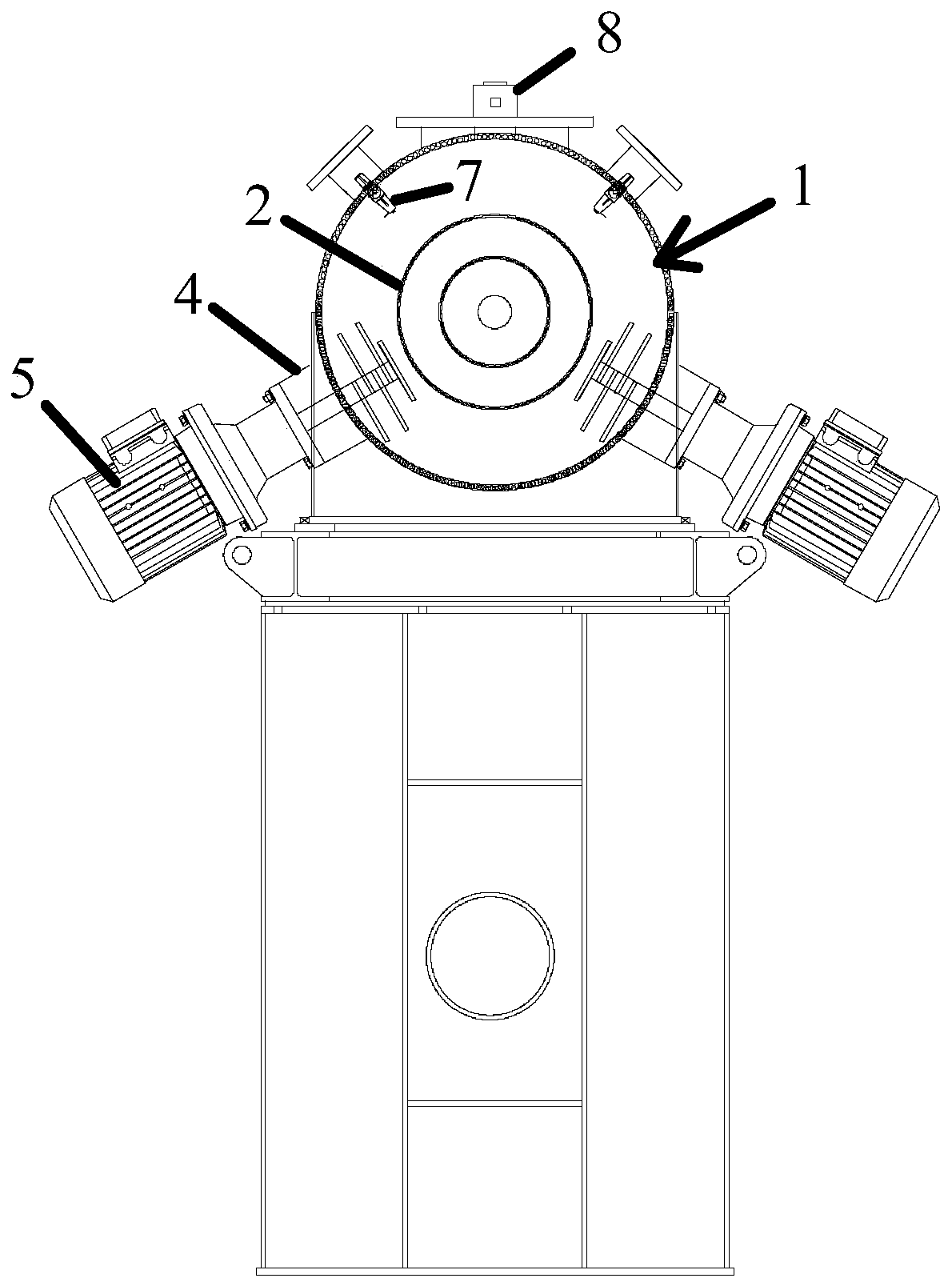

[0043] A kind of powder mixer is recorded, and the powder mixer is a powder metallurgy friction material mixer that can realize the function of segmented feeding, such as Figure 1 to Figure 3 As shown, the powder mixer includes:

[0044] A mixing bin 1, the mixing bin 1 is provided with a feed port 8 for the powder metallurgy friction material to enter;

[0045] The main screw reamer 2 is arranged in the mixing bin 1 and is driven to rotate along its circumferential direction. The first variable speed drive mechanism 3 is connected with the main screw reamer 2 to drive the main screw reamer 2 Variable speed rotation; the pitch value of the part of the helical main reamer 2 close to the feed port 8 is greater than the pitch value of the part of the helical main reamer 2 far away from the feed port 8 . Moreover, the pitch value of the helical main reamer 2 gradually increases toward the direction close to the feed port 8; because the feed port 8 must be set on the mixing bin 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com