High-nickel ternary positive electrode material, and preparation method and application thereof

A cathode material, high nickel technology, applied in chemical instruments and methods, electrical components, battery electrodes, etc., can solve the problem of not effectively reducing the amount of residual alkali on the surface of high nickel ternary cathode materials, and improve processing performance and safety performance problem, the effect of reducing the amount of residual alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

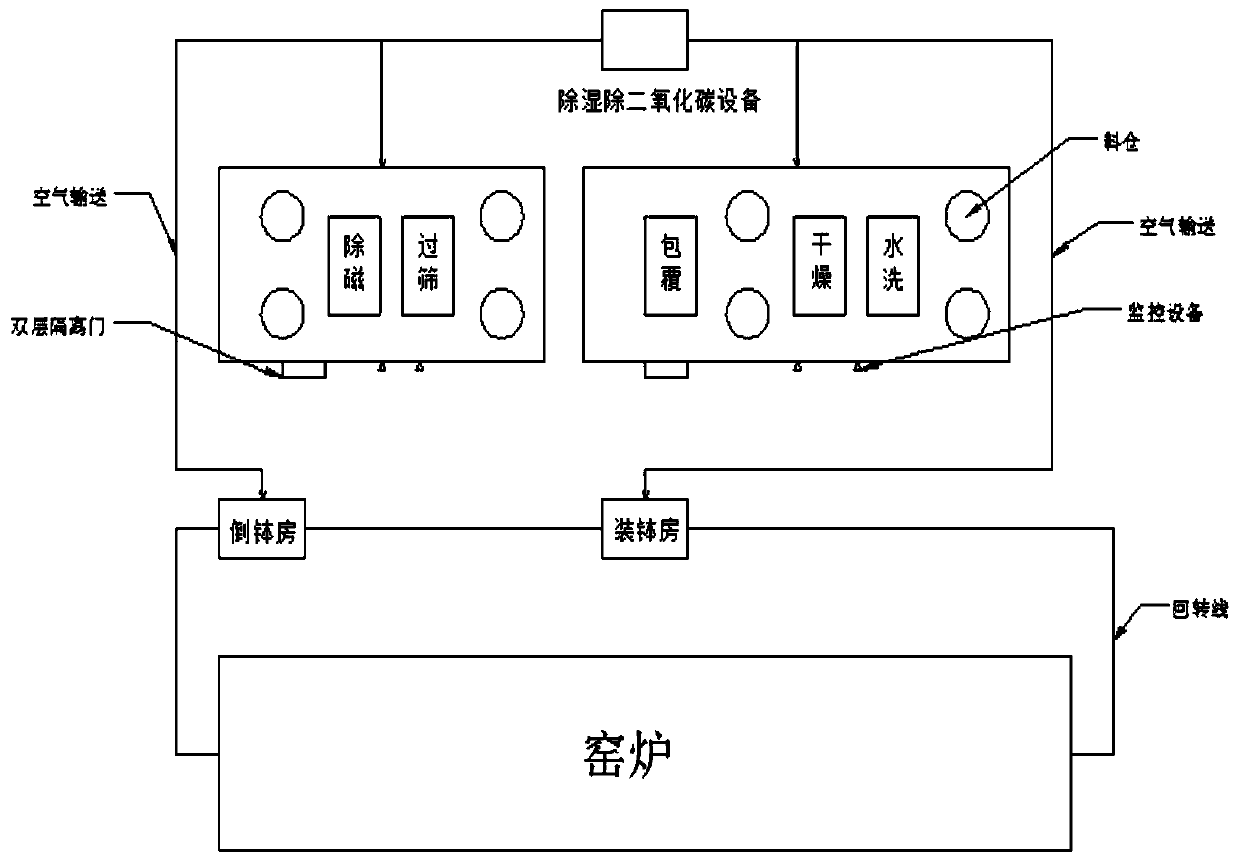

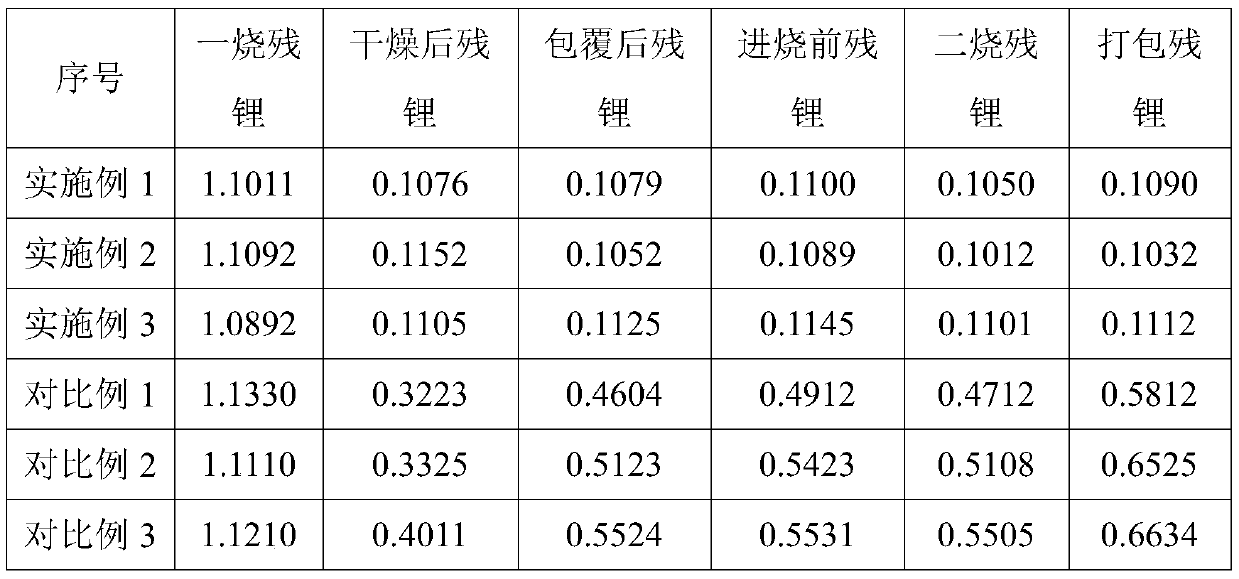

[0029] A method for preparing a high-nickel ternary positive electrode material, comprising the steps of:

[0030] (1) Add 811 ternary precursor and lithium hydroxide to a high-speed mixer and mix for 20 minutes according to the metal to lithium molar ratio of 1:1.045;

[0031] (2) Put the mixed materials into a sagger, put them into a primary sintering furnace, set the sintering temperature curve, and feed oxygen at the same time to carry out high-temperature sintering. The sintering temperature is 810°C, and the holding time is 14 hours;

[0032] (3) After the primary sintering is completed and the temperature is lowered, the material is crushed to obtain a primary sintered product, and the residual lithium is measured;

[0033] (4) Turn on the dehumidification and carbon dioxide removal equipment, and continuously pass the dehumidified and decarbonated air into the airtight drying room. The monitoring equipment in the drying room shows that the moisture content is 8.32ppm, ...

Embodiment 2

[0038] A method for preparing a high-nickel ternary positive electrode material, comprising the steps of:

[0039] (1) Add 811 ternary precursor and lithium hydroxide to a high-speed mixer and mix for 20 minutes according to the metal to lithium molar ratio of 1:1.045;

[0040] (2) Put the mixed materials into a sagger, put them into a primary sintering furnace, set the sintering temperature curve, and feed oxygen at the same time to carry out high-temperature sintering. The sintering temperature is 810°C, and the holding time is 14 hours;

[0041] (3) After the primary sintering is completed and the temperature is lowered, the material is crushed to obtain a primary sintered product, and the residual lithium is measured;

[0042] (4) Turn on the dehumidification and carbon dioxide removal equipment, and continue to pass the dehumidified and decarbonated air into the airtight drying room. The monitoring equipment in the drying room shows that the moisture content is 6.89ppm, t...

Embodiment 3

[0047] A method for preparing a high-nickel ternary positive electrode material, comprising the steps of:

[0048] (1) Add 811 ternary precursor and lithium hydroxide to a high-speed mixer and mix for 20 minutes according to the metal to lithium molar ratio of 1:1.045;

[0049] (2) Put the mixed materials into a sagger, put them into a primary sintering furnace, set the sintering temperature curve, and feed oxygen at the same time to carry out high-temperature sintering. The sintering temperature is 810°C, and the holding time is 14 hours;

[0050] (3) After the primary sintering is completed and the temperature is lowered, the material is crushed to obtain a primary sintered product, and the residual lithium is measured;

[0051] (4) Turn on the dehumidification and carbon dioxide removal equipment, and continue to pass the dehumidified and decarbonated air into the airtight drying room. The monitoring equipment in the drying room shows that the moisture content is 7.31ppm, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com