Novel low-pressure air combustion supporting torch combustor

A torch combustion and air technology, which is applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve safety risks such as big explosions, steam combustion-supporting torches are not suitable for use, and block the torch outlet, etc., to reduce equipment operation cost, save low-pressure air volume, increase mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

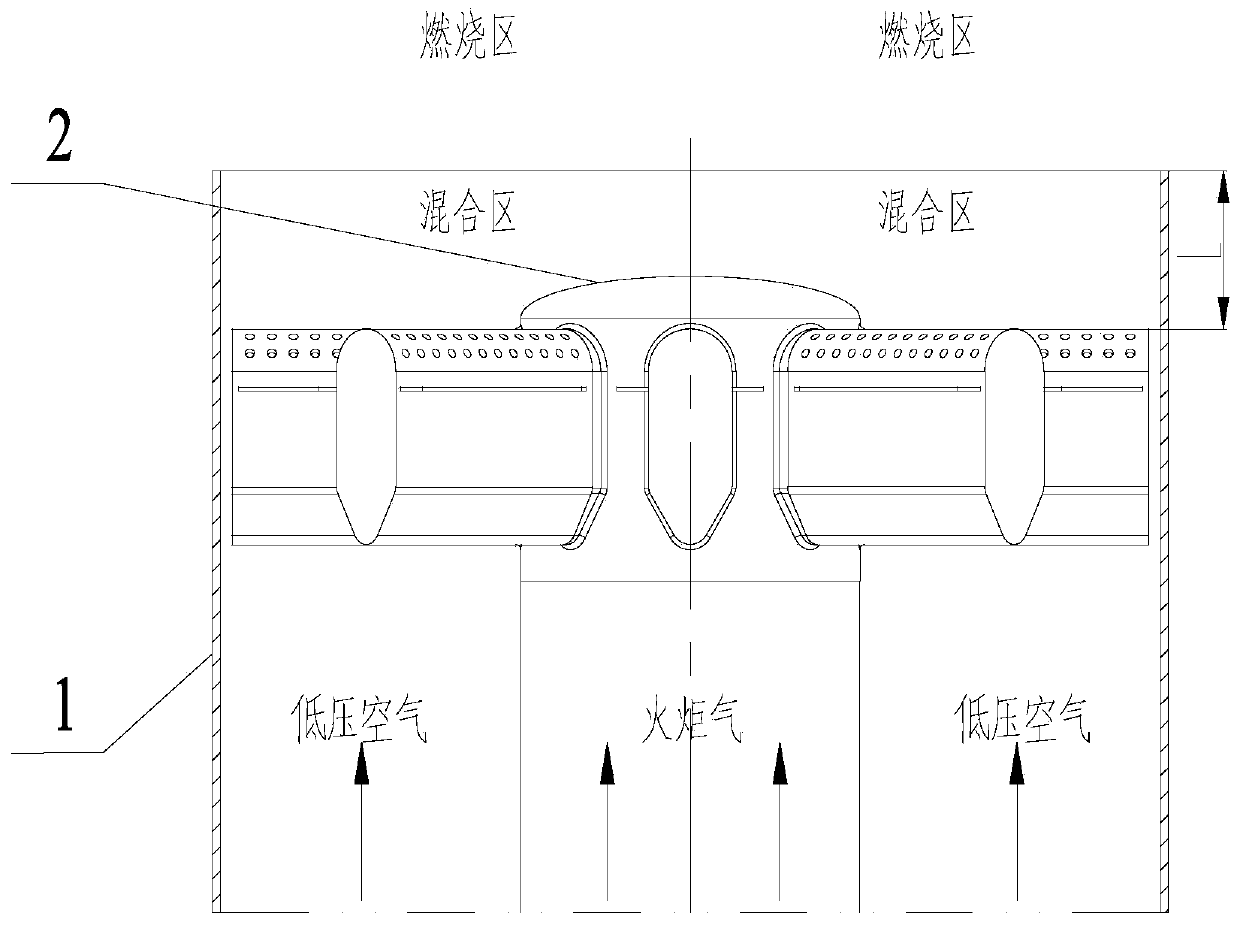

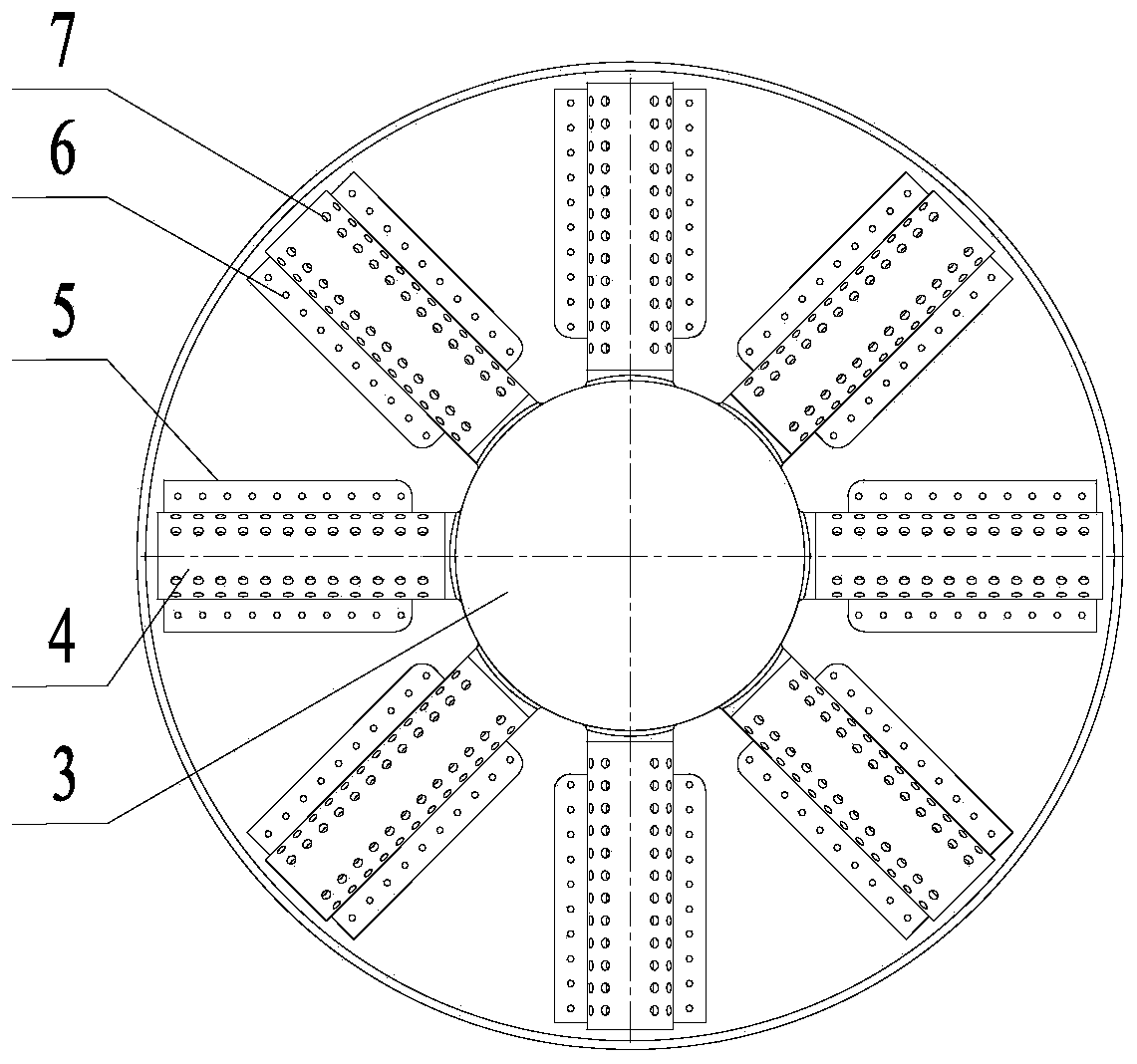

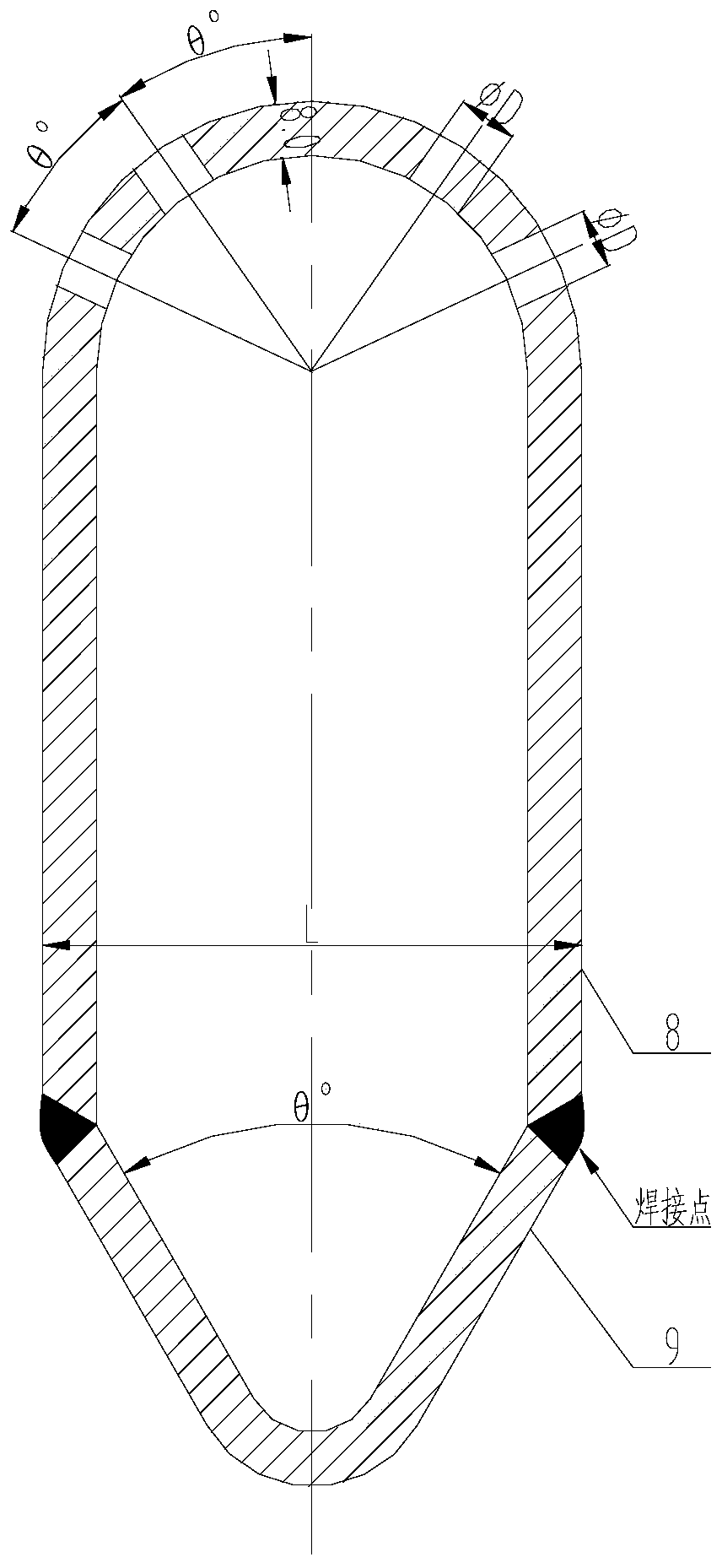

[0052] The invention relates to a novel low-pressure air combustion-supporting torch burner, which has the advantages of good smoke elimination effect, preventing burning loss and smoldering, and the like. Now with examples to illustrate as follows.

[0053] This burner is used in an elevated flare project, and the flare gas is oilfield associated gas. The setting of the torch burner is as follows: the air cylinder adopts DN900, the torch head cylinder adopts DN300, the gas distributor is equipped with 8 arms, and each arm is punched in 4 rows, and the holes in each row are aligned (non-staggered) , 12 holes in each column, 48 holes in total. The distance between the fin plate and the upper semicircle of the support arm is 10mm. Specifically, the distance from the intersection of the upper semicircle and the side straight line is 10mm. The distance between the fin plate and the arm is 3 holes shorter than the length of the support arm, that is, 8 holes are reserved as the fla...

Embodiment 2

[0056] The invention relates to a novel low-pressure air combustion-supporting torch burner, which has the advantages of good smoke elimination effect, high utilization rate of combustion-supporting medium, and saving public works consumption. Now with examples to illustrate as follows.

[0057] In the laboratory, the burner is compared with the jacket structure of the straight-through gas distributor. In this test, propylene is used as the main flare gas component. The amount of low-pressure air consumed when achieving the same smoke elimination effect (zero-level Ringelmann blackness), the burner with the structure of the invention can save 10% of air consumption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com