Knife edge device for measuring focal length in adjustment of reflection long-focus telescope and measuring method

A telescope and knife edge technology, which is used in measuring devices, optical instrument testing, testing optical performance and other directions, can solve the problems of low optical installation and adjustment efficiency of large-diameter telescope systems, installation accuracy affecting test accuracy, etc., to improve test repeatability and improve Test efficiency, easy-to-build effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

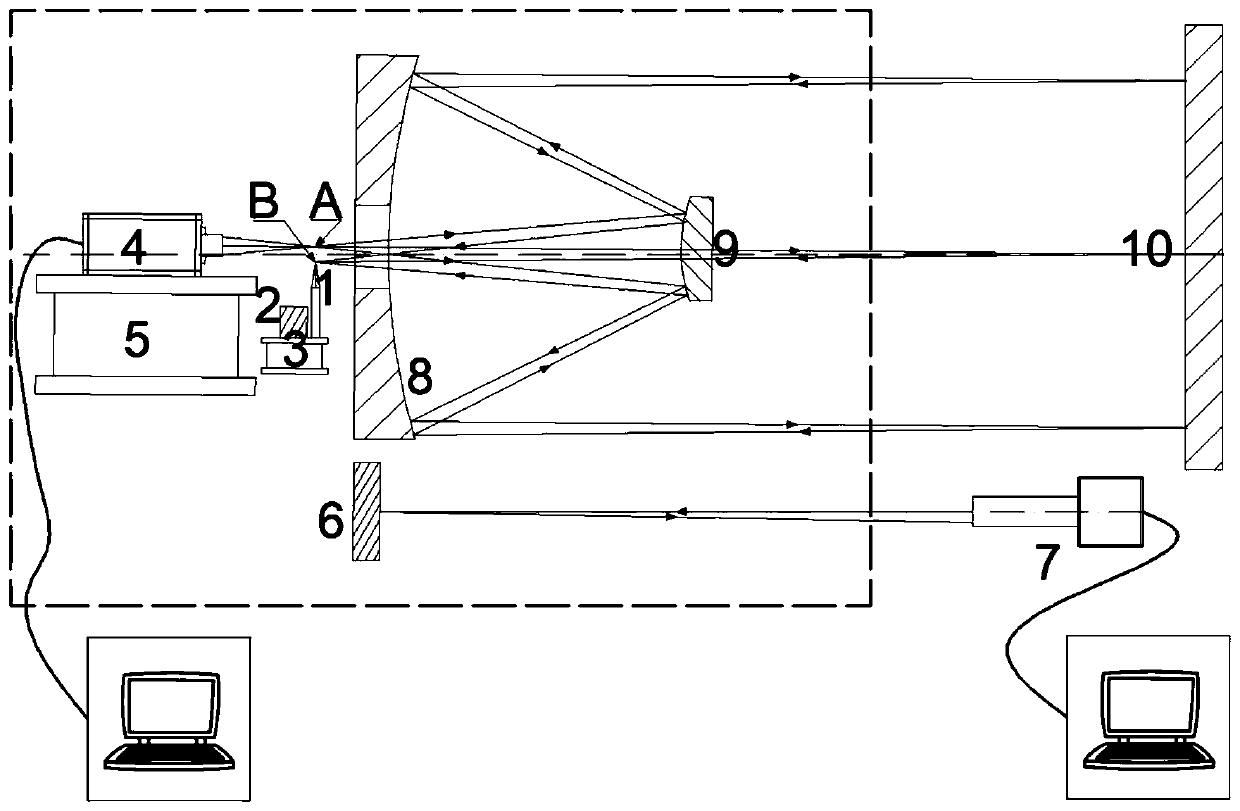

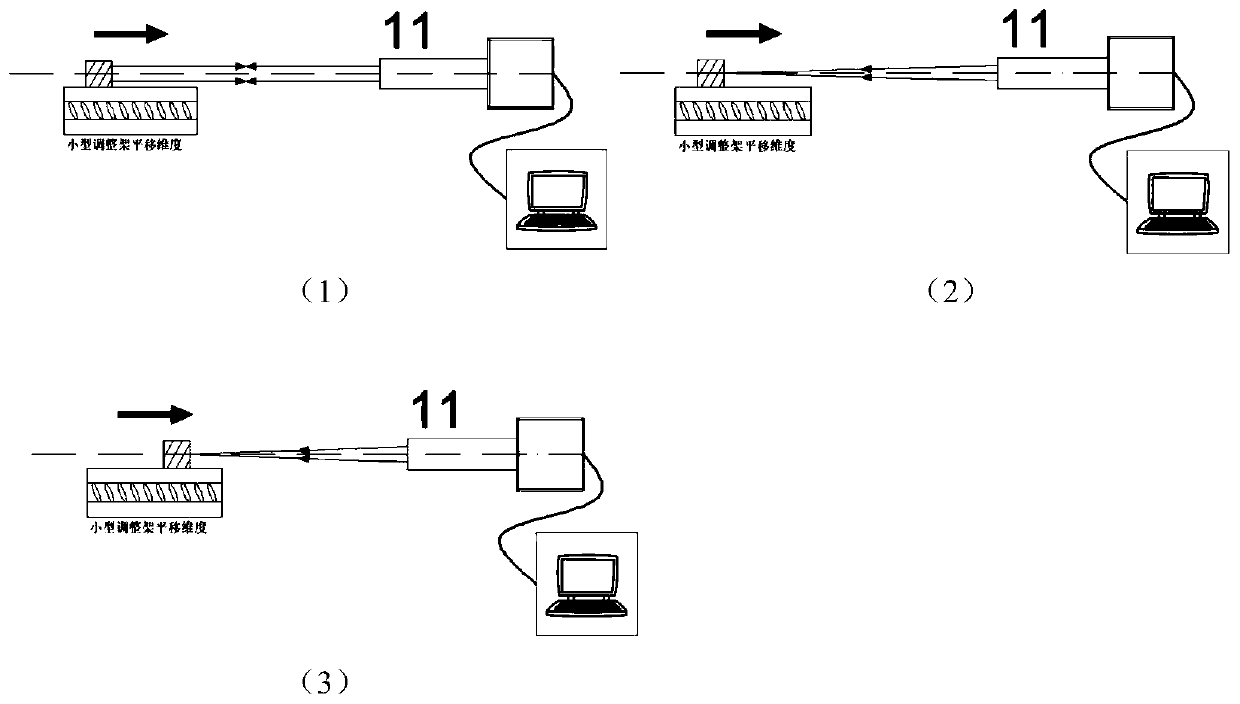

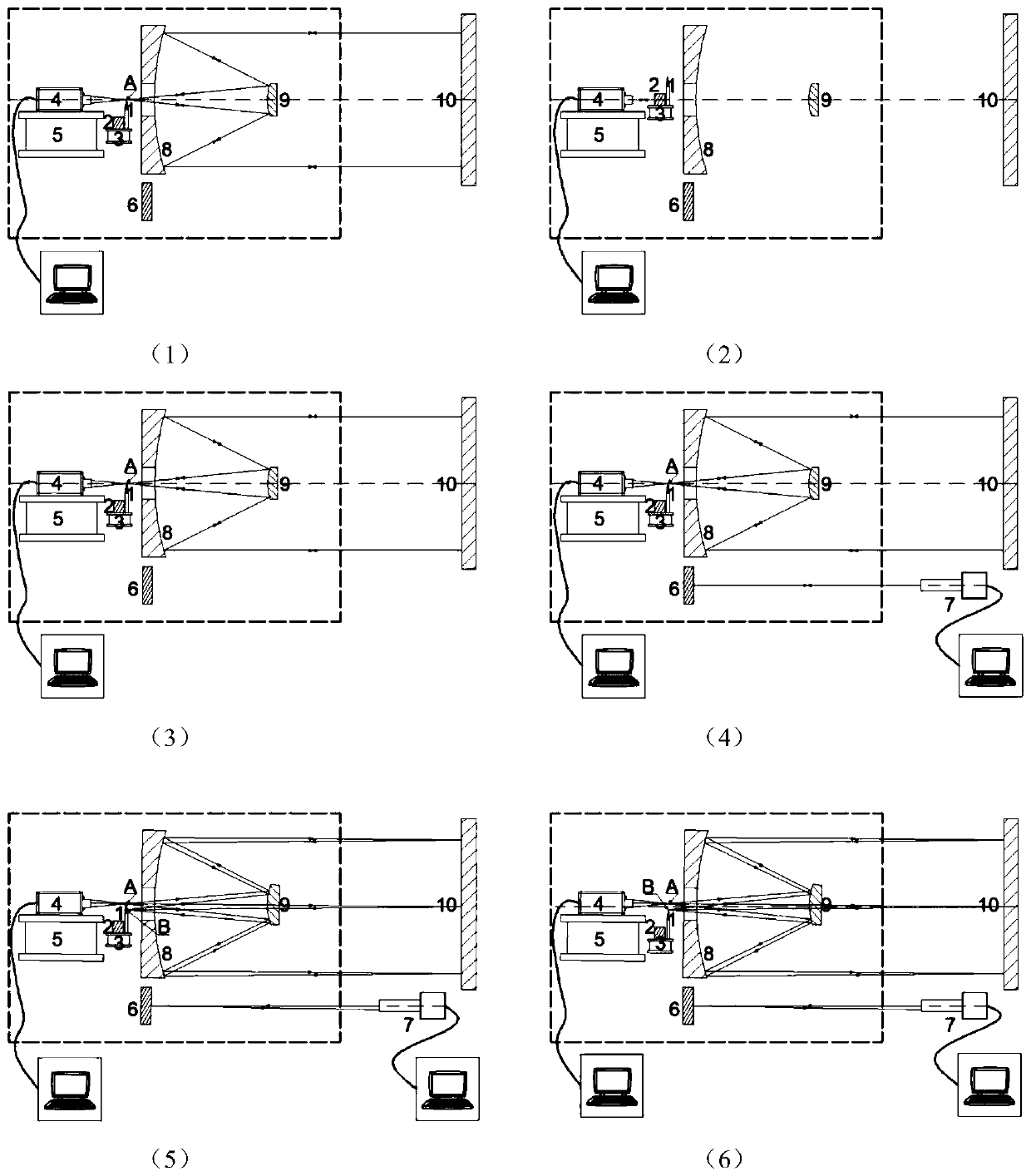

[0018] The implementation examples of the patented method will be described in detail below in conjunction with the accompanying drawings.

[0019] The main components used in the present invention are described:

[0020] Cube prism 2: customized processing, side length 35mm, 90-degree angle difference and pyramid difference are better than 3 seconds, each surface type RMS is better than 1 / 15 wavelength@633nm, six-sided aluminum-coated reflective film, one of which is engraved with Reticle, material K9.

[0021] Photoelectric autocollimator 8: TriAngle's model is TA500-57 photoelectric autocollimator, with a light aperture of 50mm, a field of view of 1300X950 seconds, a resolution of 0.02 seconds, and a repeatability of ±0.05 seconds.

[0022] Readable and high-precision five-dimensional adjustment frame 3: used to adjust the orientation of the knife edge, including horizontal dimension adjustment, front and rear dimension adjustment, high and low dimension adjustment, pitch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com