Intelligent steel slag detection method and system based on convolutional neural network

A convolutional neural network and neural network technology, applied in the field of intelligent steel slag detection, can solve the problems of unsatisfactory steel slag detection, high transformation and maintenance costs, and short coil service life, so as to avoid display feature extraction and realize effective distinction , Improve the effect of recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit this invention.

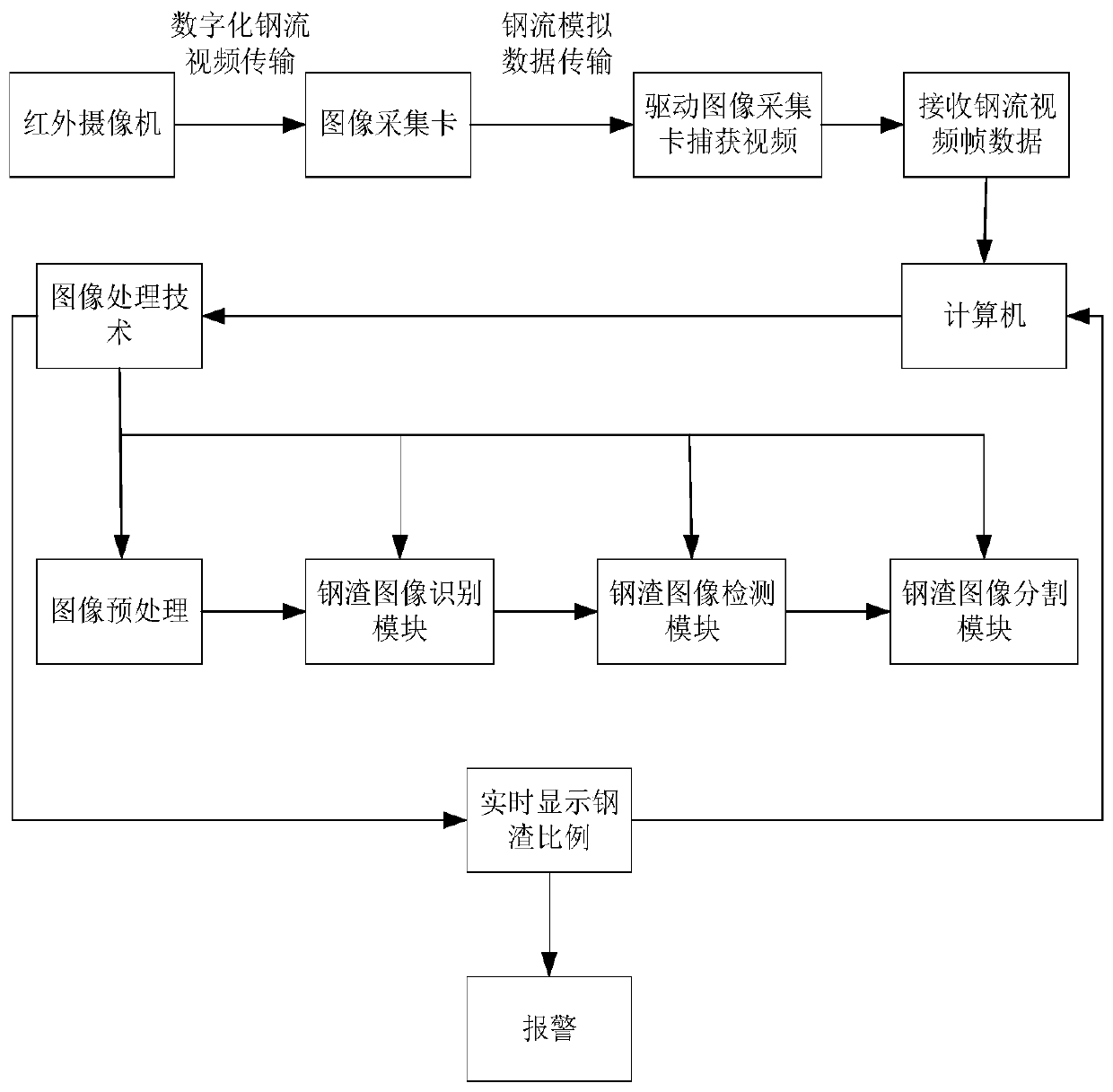

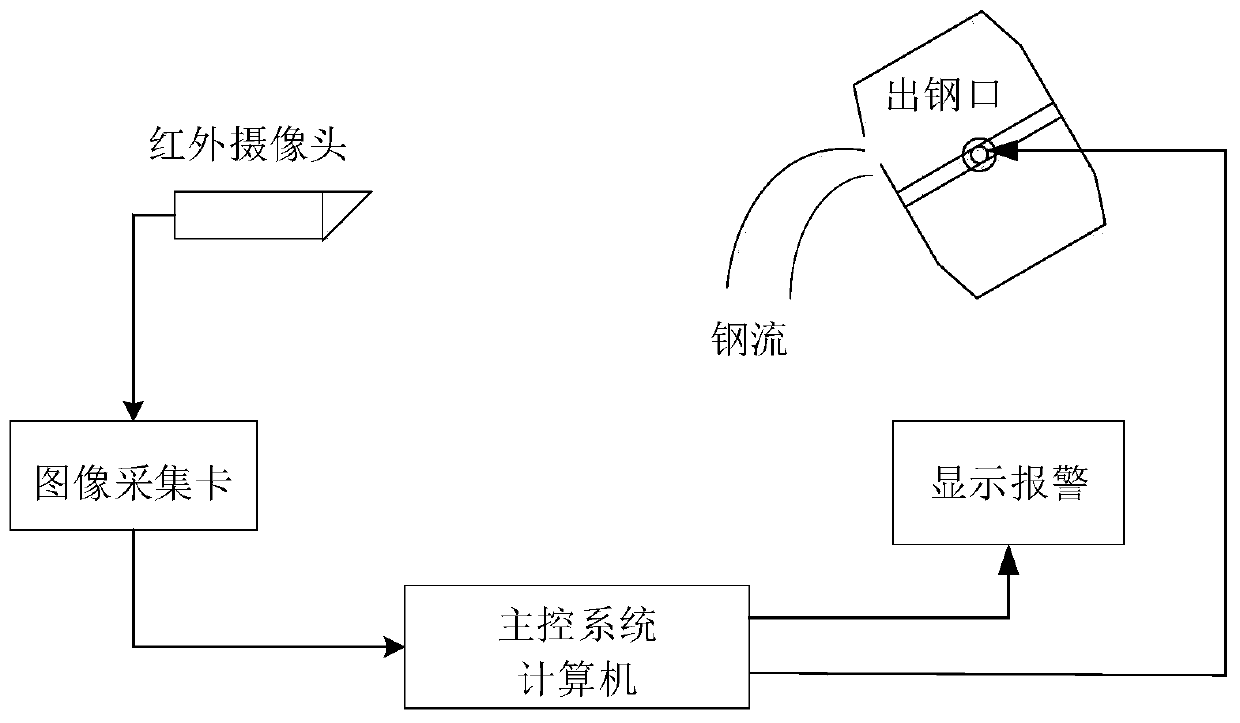

[0059] Figure 1-2 It is the overall structure diagram of the intelligent steel slag detection system based on the convolutional neural network according to the embodiment of the present invention; figure 2 Infrared camera) collects steel slag video images, and uses a notebook computer as the terminal control platform and display hardware, which has the advantages of flexible use and easy maintenance.

[0060] The basic configuration of the notebook terminal used in this embodiment is as follows:

[0061] (1) Processor: Intel Core i7-8550M, main frequency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com