Heracleum barbatum Ledeb instant powder obtained by vacuum freezing and drying

A technology of vacuum freeze-drying and instant powder, applied in the field of freeze-drying, can solve the problems of high production costs, achieve the effects of reducing production costs, stimulating economic development, and easy control of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

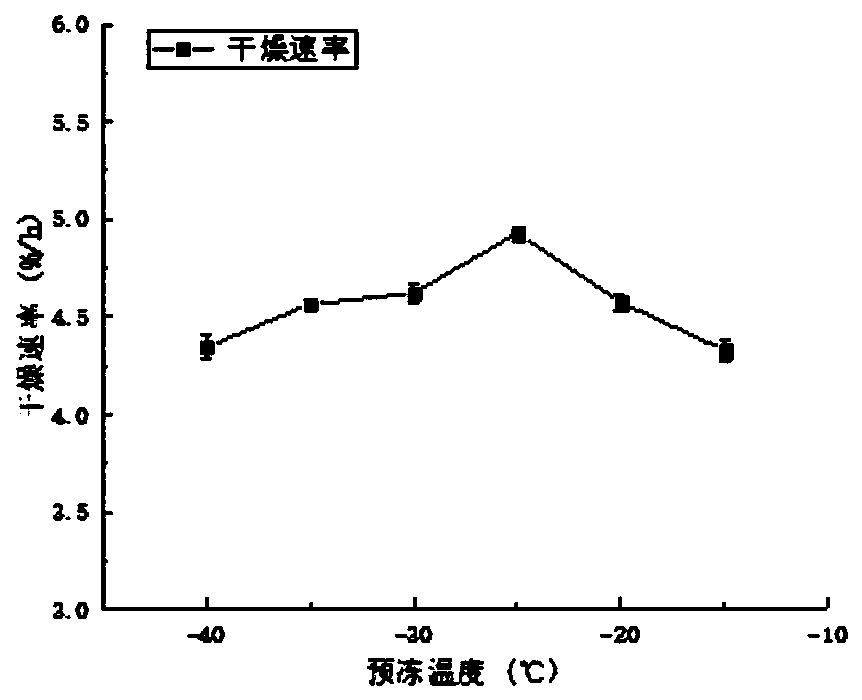

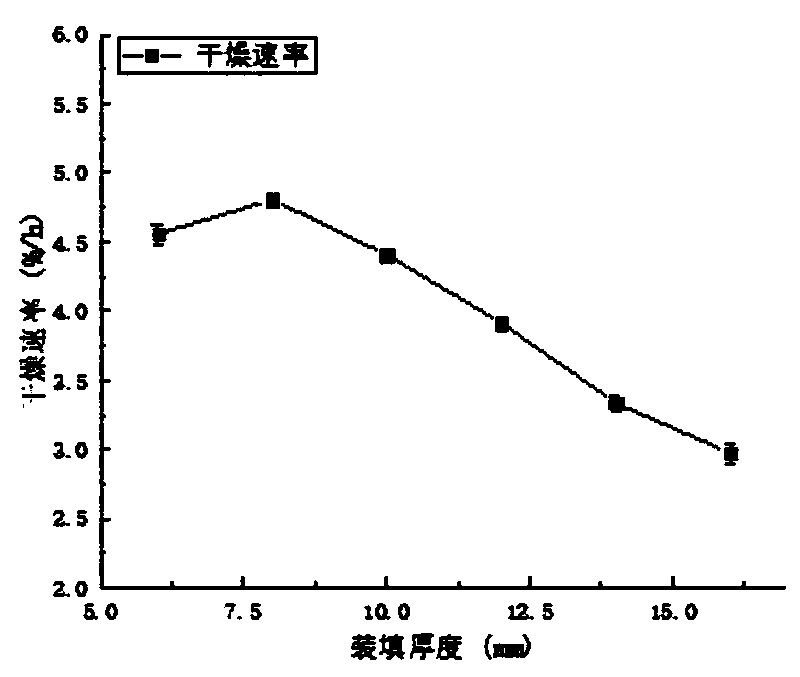

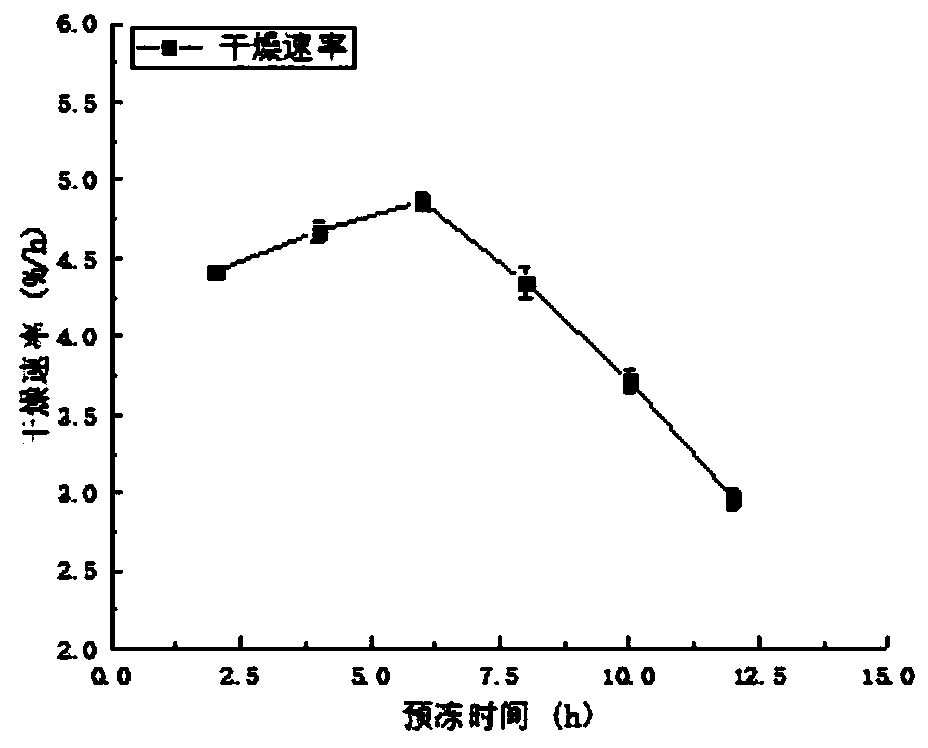

[0044] Add the freshly squeezed and filtered old celery into the old celery preparation in proportion for later use. Clean the material tray of the freeze dryer and dry it in a ventilated place. Pour the old celery preparation liquid onto the material tray. Use a ruler to accurately measure the liquid height to 8mm, and the page is regular and stable, and there is no residual liquid on the tray wall. Pre-freezing: place the material tray containing the old celery liquid on the plate in the freeze-drying chamber of the vacuum freeze-drying machine, and cover the freeze-drying cover. Start the compressor of the vacuum freeze dryer to refrigerate, the temperature of the material is lowered to -25°C, and maintained for 6 hours. Vacuum drying: Turn on the cold trap refrigeration mode, and turn on the vacuum pump and vacuum gauge to evacuate the freeze-drying chamber. The refrigeration temperature of the cold trap device is controlled at -60°C, and the vacuum degree is maintained at...

Embodiment 2

[0046] Add the freshly squeezed and filtered old celery into the old celery preparation in proportion for later use. Clean the material tray of the freeze dryer and dry it in a ventilated place. Pour the old celery preparation liquid onto the material tray. Use a ruler to accurately measure the liquid height to 8mm, and the page is regular and stable, and there is no residual liquid on the tray wall. Pre-freezing: place the material tray containing the old celery liquid on the plate in the freeze-drying chamber of the vacuum freeze-drying machine, and cover the freeze-drying cover. Start the compressor of the vacuum freeze dryer to refrigerate, the temperature of the material is lowered to -30°C, and maintained for 5 hours. Vacuum drying: Turn on the cold trap refrigeration mode, and turn on the vacuum pump and vacuum gauge to evacuate the freeze-drying chamber. The refrigeration temperature of the cold trap device is controlled at -60°C, and the vacuum degree is maintained at...

Embodiment 3

[0048] Add the freshly squeezed and filtered old celery into the old celery preparation in proportion for later use. Clean the material tray of the freeze dryer and dry it in a ventilated place. Pour the old celery preparation liquid onto the material tray. Use a ruler to accurately measure the liquid height to 8mm, and the page is regular and stable, and there is no residual liquid on the tray wall. Pre-freezing: place the material tray containing the old celery liquid on the plate in the freeze-drying chamber of the vacuum freeze-drying machine, and cover the freeze-drying cover. Start the compressor of the vacuum freeze dryer to refrigerate, the temperature of the material is dropped to -28°C, and maintained for 5.5 hours. Vacuum drying: Turn on the cold trap refrigeration mode, and turn on the vacuum pump and vacuum gauge to evacuate the freeze-drying chamber. The refrigeration temperature of the cold trap device is controlled at -60°C, and the vacuum degree is maintained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com