Derusting equipment for hardware processing

A kind of hardware and equipment technology, applied in the field of rust removal equipment, can solve the problems of mechanical properties of metal materials decline, affect material strength, increase workload, etc., achieve obvious rust removal effect, prolong service life, and increase the effect of friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

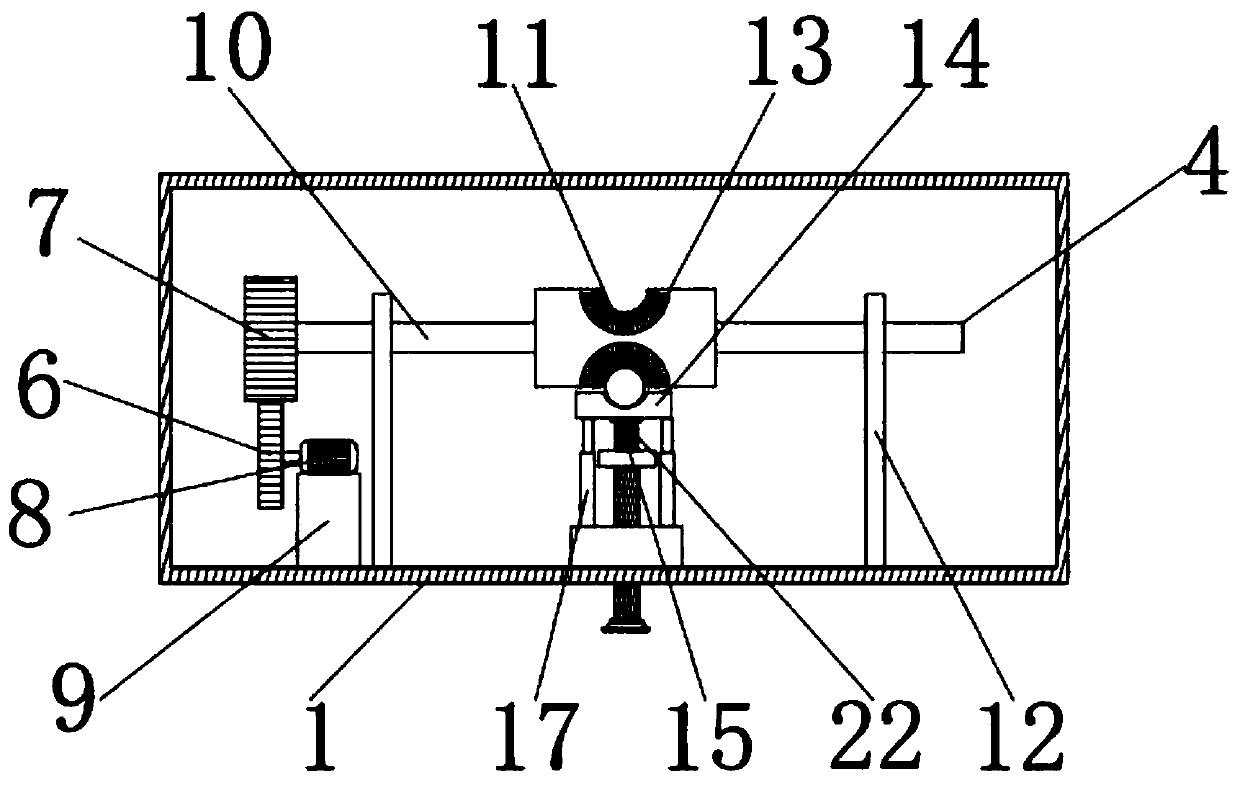

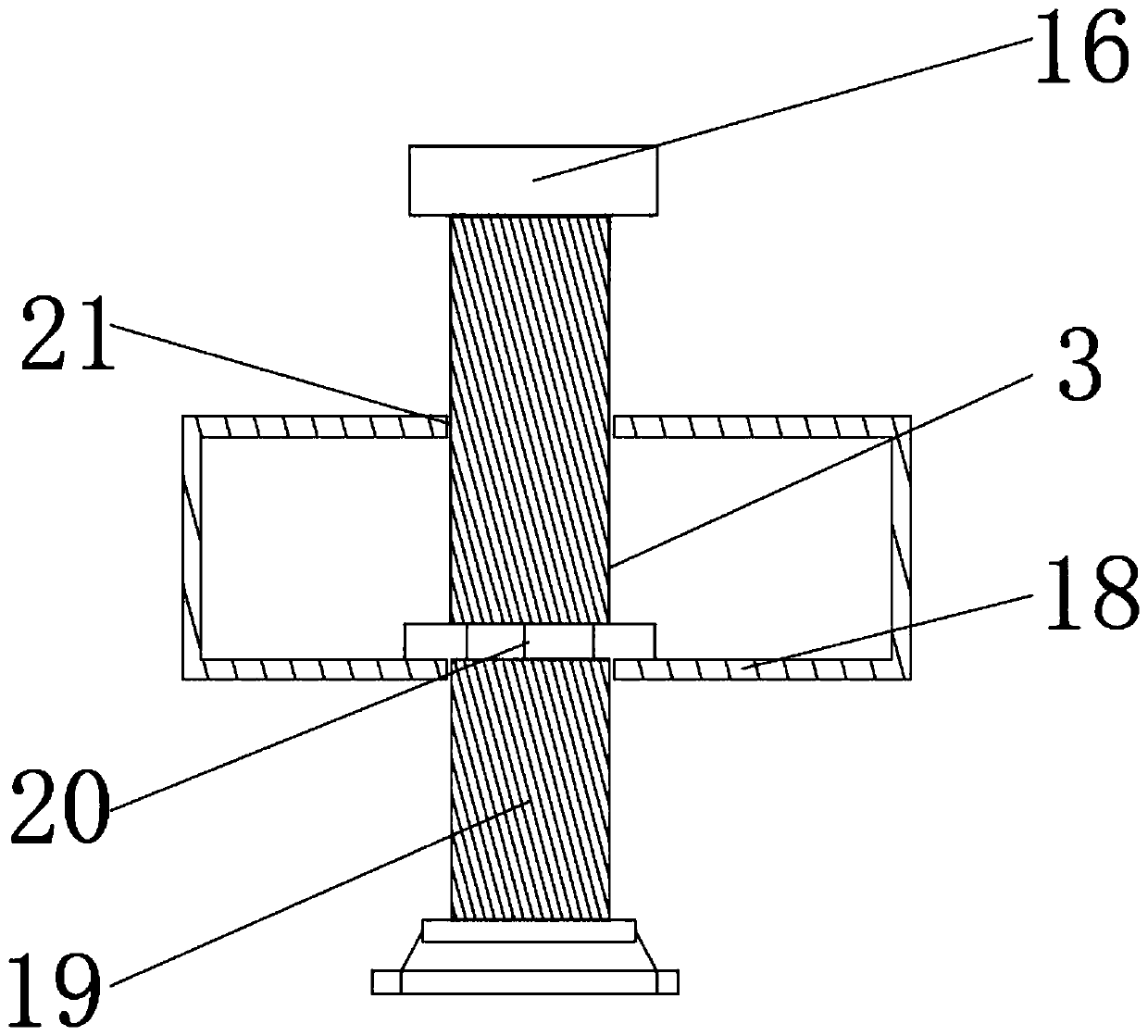

[0022] Concrete embodiment: When we need to derust the steel bar, the steel bar is inserted in the box body 1, and the steel bar is moved forward slowly at a uniform speed, and the motor 8 in the derusting device 4 drives the rotating shaft 10 to rotate rapidly, so that the derusting brush 11 and The steel bar is constantly rubbed, and the rust around the steel bar and the inside of the thread is cleaned up. The threaded rod 19 adjusts the height according to the thickness of the steel bar, and presses the fixing plate 16 upwards. Reaching the effect of increasing frictional force, telescopic rod 17 prevents lifting assembly 3 from shaking left and right when adjusting up and down, and spring 15 makes this lifting assembly have certain elasticity, and derusting effect is better, easy to operate, convenient and practical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com