Prefabricated broken bridge partition wall module

A prefabricated, bridge-breaking technology, applied in the direction of walls, sound insulation, insulating layers, etc., can solve the problems of poor reliability and stability of the structure, and achieve the effect of less pollution and less noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

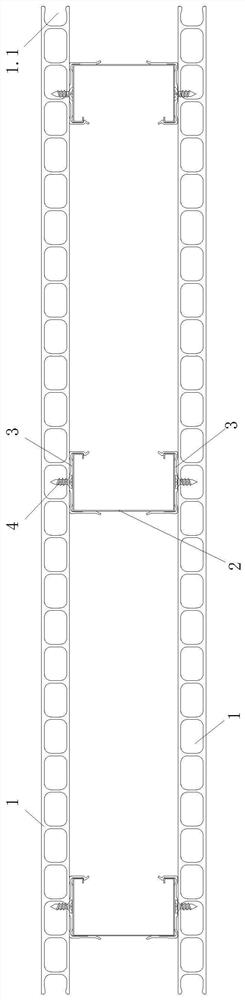

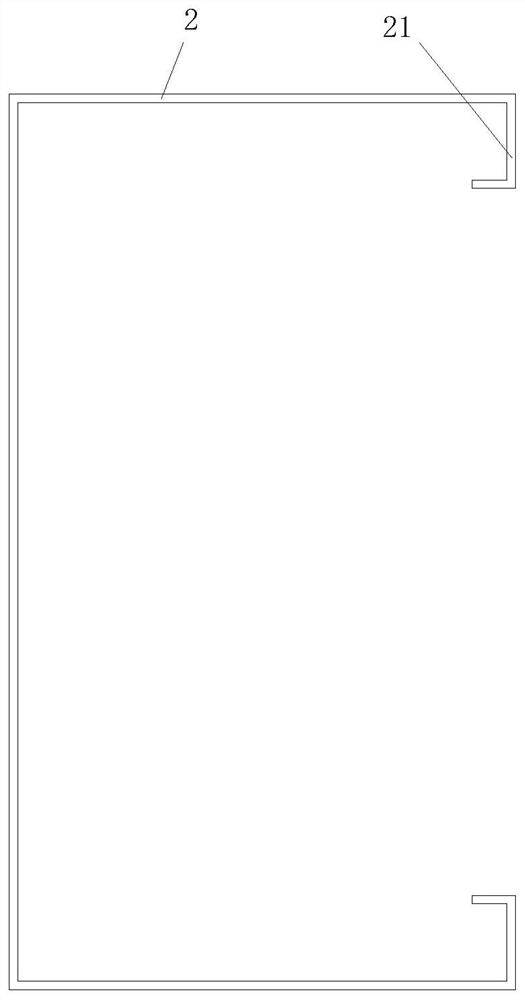

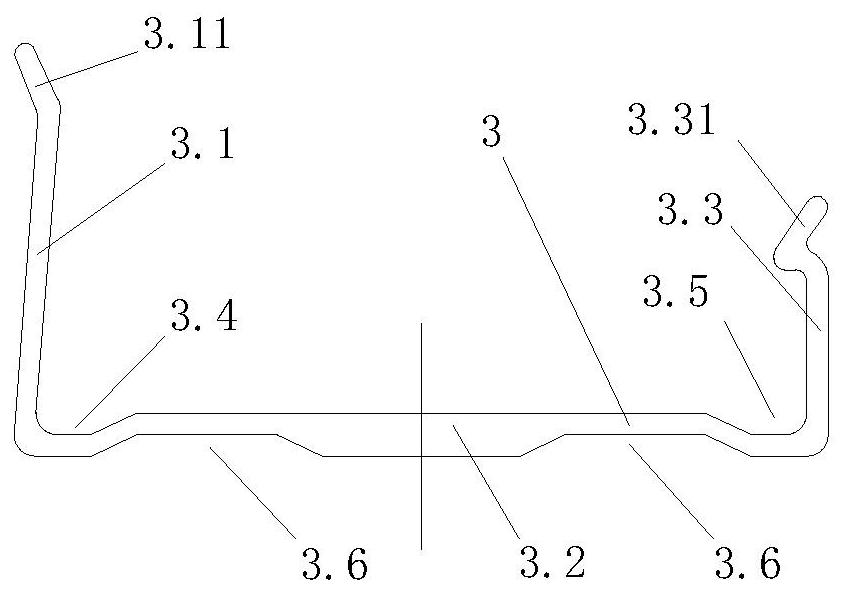

[0017] Such as Figure 1-3 As shown, the present invention includes a partition wall stone-plastic panel 1, a keel 2, a U-shaped clip 3, and a sound insulation felt not shown in the figure. The sound insulation felt and the backboard of the partition wall stone-plastic panel 1 are fixed together by air gun nails not shown in the figure. Countersunk holes are provided on the U-shaped fasteners 3, and several U-shaped fasteners 3 are respectively fixed on the corresponding positions of the two partition wall stone-plastic panels 1 by countersunk screws 4, and the two ends of corresponding several keels 2 are respectively clamped on the corresponding to the bayonet of the U-shaped clip 3. Both ends of each partition wall stone-plastic panel 1 are provided with a card slot 1.1. Wherein, the keel 2 is an integrated light steel keel, and the U-shaped free edge of the keel 2 is bent to form a side groove 21 to increase rigidity. The U-shaped clip 3 is composed of the first side 3....

Embodiment 2

[0019] Such as Figure 2-4 As shown, the difference between the second embodiment and the first embodiment is that the keel 2 in the second embodiment is composed of the first keel 2.1, the connecting keel 2.2, and the second keel 2.3 connected in sequence. The cross-section of the connecting keel 2.2 is groove-shaped. The cross section of the first keel 2.1 includes a first inner section 2.11, a first middle section 2.12, and a first outer section 2.13. The cross section of the second keel 2.3 includes a second inner section 2.31, a second middle section 2.32, and a second outer section 2.33. Both the free edges of the first outer section 2.13 and the second outer section 2.33 are bent to form a side groove 21 for increasing rigidity. The first inner section 2.11 and the first middle section 2.12 are connected at right angles, and the first inner section 2.11 is inserted into the groove connecting the keel 2.2; the free end of the second inner section 2.31 is groove-shaped,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com