Device and method for removing grease from wax gourd seeds

A technology for wax gourd seeds and granules, which is applied in the field of wax gourd seed granule oil removal devices, can solve the problems of poor particle fluidity, inability to measure bulk density, and inability to sub-pack.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0032] It should be noted that the structures, proportions, sizes, etc. shown in the drawings attached to this specification are only used to match the content disclosed in the specification, for those who are familiar with this technology to understand and read, and are not used to limit the implementation of the present invention Any modification of the structure, change of the proportional relationship or adjustment of the size shall still fall within the scope of the technical content disclosed in the present invention without affecting the effect and the purpose of the present invention. within the scope covered.

[0033] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the...

Embodiment 1

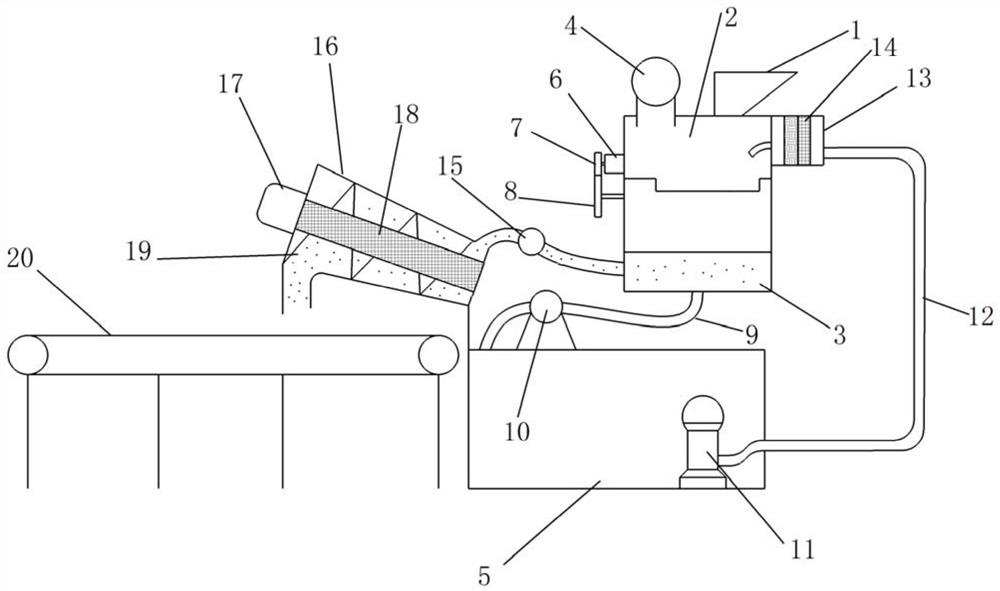

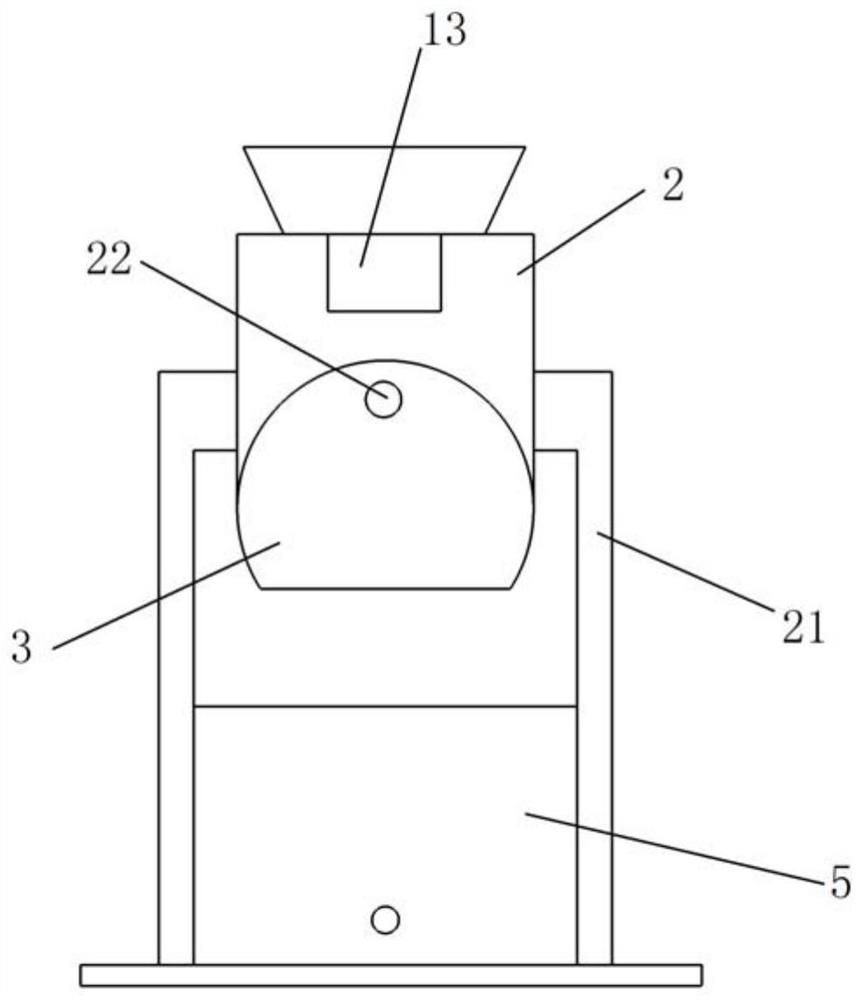

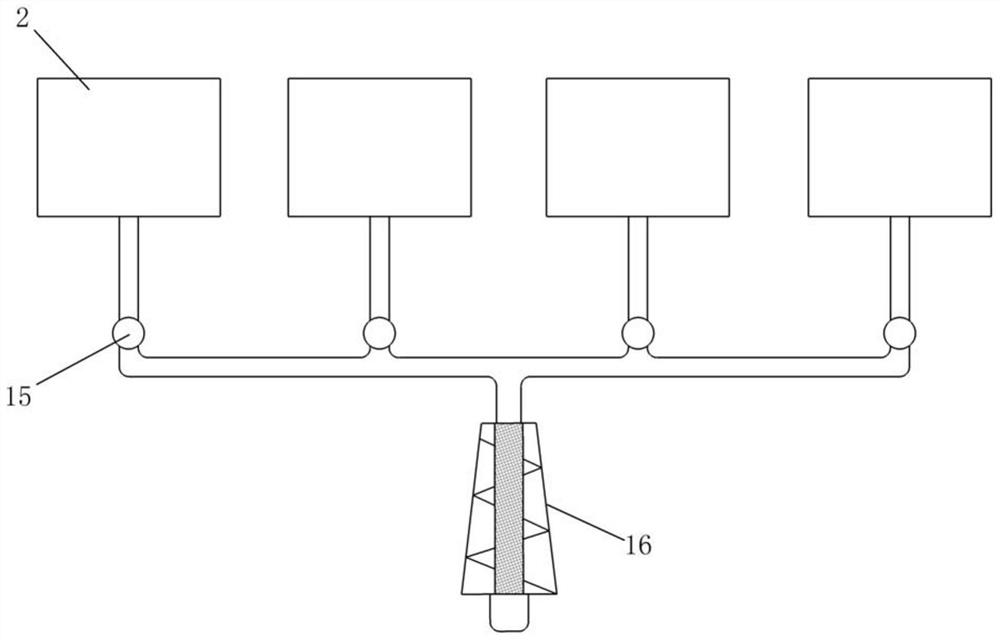

[0035] A kind of wax gourd seed particle grease removal device, comprises operating cabin, liquid storage tank 5, pneumatic conveyer 16 and transmission device 20; Described operating cabin comprises upper box body 2 and lower box body 3, and described upper box body 2 lower ends and The upper end of the lower box 3 is hinged and fixed by the rotating shaft 22 and the upper part of the lower box 3 is embedded in the inner cavity of the upper box 2, and the upper box 2 and the lower box 3 can swing around the rotating shaft 22; the lower box 3 The liquid storage tank 5 is connected to the liquid storage tank 5 through the hose 9 and the first pump body 10, and a filter screen is provided at the connection between the hose 9 and the lower box 3, and the liquid storage tank 5 is connected to the upper tank 5 through the second pump body 11 and the pipe 12. The box body 2 is connected; the connection between the pipe 12 and the upper box body 2 is provided with a filter box 13; the...

Embodiment 2

[0045] A kind of method of wax gourd seed granule grease removal device,

[0046] S1. Add a certain amount of wax gourd seeds to be processed into the lower box 3 through the feeding port 1, and pump the liquid storage tank 5 into the lower box 3 through the second pump body 11 to 1.5 times the temperature heated to 30-60°C. petroleum ether;

[0047] S2. The driving motor 6 drives the lower box 3 to swing around the rotating shaft 22 for 3 hours;

[0048]S3. Pump the petroleum ether in the lower box 3 into the liquid storage tank 5 through the first pump body 10;

[0049] S4, start the dryer 4 to continuously dry the wax gourd seed particles, and at the same time swing the lower box 3 until the petroleum ether is evaporated to obtain dry wax gourd seed particles;

[0050] S5, start the pneumatic conveyor 16 to suck the wax gourd seeds in the lower box 3 into the cone-shaped conveying cylinder and centrifugally disperse them through the spiral channel 19, and then reach the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com