Microplate sample injection indicating system

A technology of micro-orifice plates and instructions, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as easy to add wrong holes, increase error rate of sample addition, and reduce test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

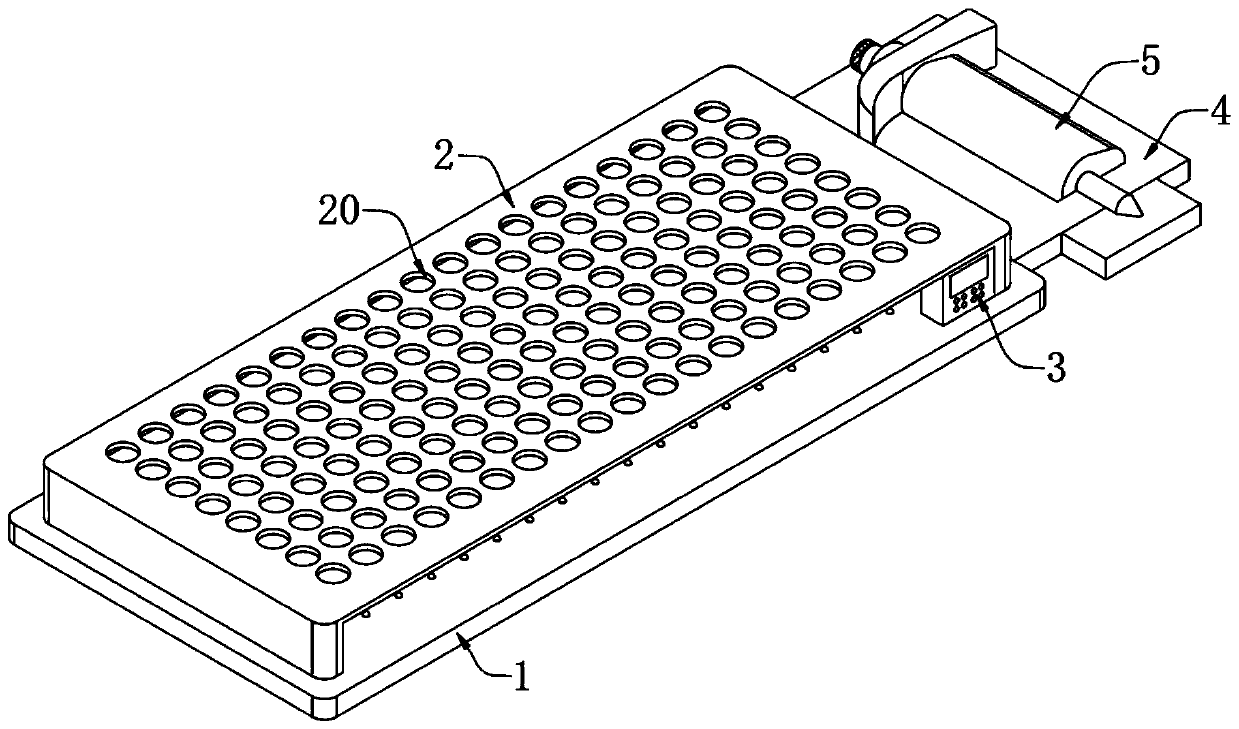

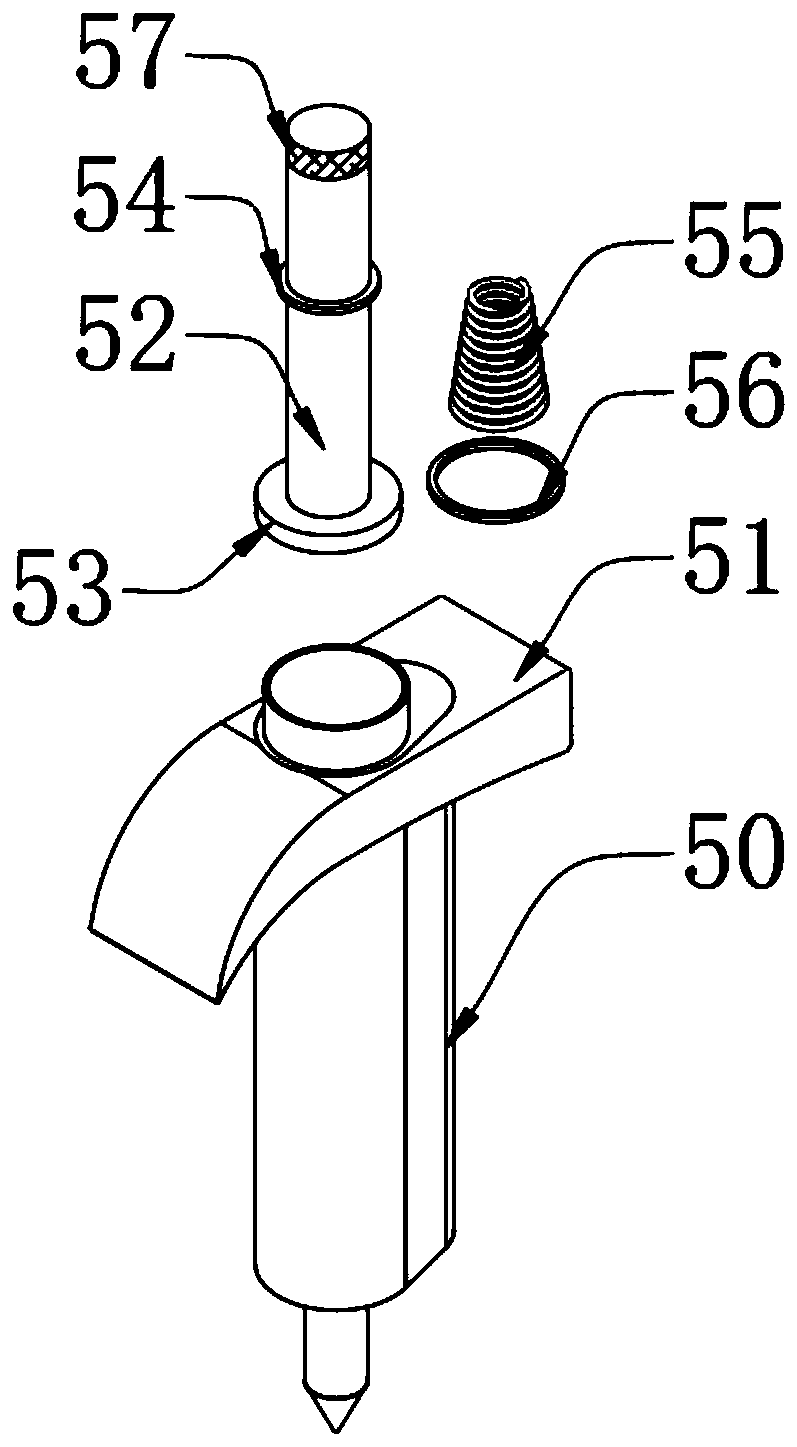

[0101] A microplate loading indicator system, such as Figure 1 to Figure 3 As shown, including the base 1, the top of the base 1 is provided with a placement box 2, the rear side of the base 1 is provided with a placement plate 4, and the upper surface of the placement plate 4 is provided with a gun slot 40, and a sample addition is embedded in the gun slot 40. The gun 5, the sample adding gun 5 comprises a gun barrel 50, the position of the side wall of the gun barrel 50 near the end is provided with an arc-shaped plate 51, an injection rod 52 is installed in the gun barrel 50, and a piston 53 is arranged at the end of the injection rod 52, The injection rod 52 is covered with a spring 55 , and the two ends of the spring 55 are respectively installed with a first fixing ring 54 and a second fixing ring 56 .

[0102] In this embodiment, the arc-shaped plate 51 and the gun barrel 50 are integrally formed to ensure the stability of the connection between the arc-shaped plate 51...

Embodiment 2

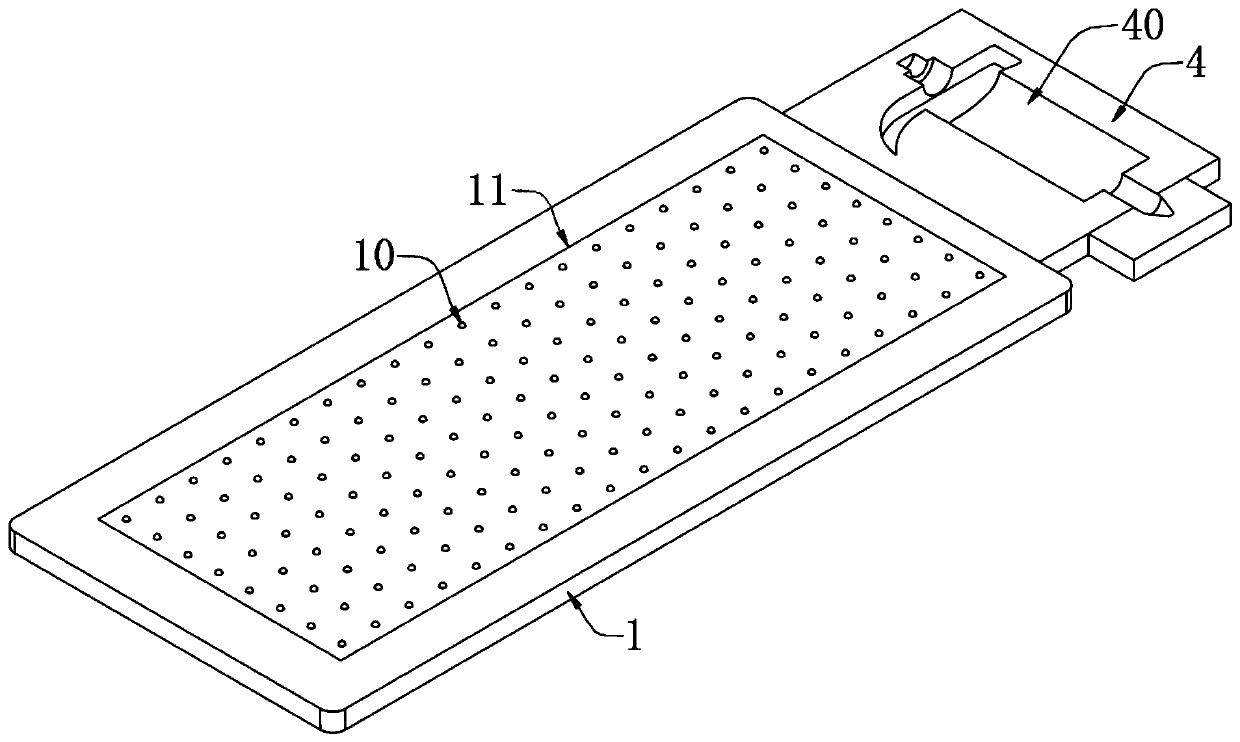

[0108] As the second embodiment of the present invention, in order to reduce the error rate and improve the experimental efficiency, the inventor sets the control system, as a preferred embodiment, such as Figure 4 to Figure 10 As shown, there is an induction device 11 installed inside the base 1, a number of indicator lights 10 are arranged at equal intervals on the upper surface of the base 1, a number of placement grooves 20 are arranged at equal intervals on the placement box 2, and a pressure sensor is installed on the top of the side wall of the injection rod 52. 57. A display panel 3 is installed on the right side wall of the storage box 2 close to the rear side, and a control system is installed inside the display panel 3. The control system includes a control module, a key module, a display module, a sensor module and a power module. The module is used to collect pressure signals and palm signals; the button module is used to count the signal data and switch the worki...

Embodiment 3

[0247] As a third embodiment of the present invention, in order to facilitate the monitoring of the sample addition process and improve the accuracy of sample addition, the inventors set up a defined successful sample addition module. As a preferred embodiment, the display panel 3 is also provided with a defined success module. The sample adding module is used for monitoring the sample adding process.

[0248] In this embodiment, the defined successful sample addition module uses an autoregressive model to process and calculate the monitored data signals.

[0249] Further, a copper plate is provided on the upper surface of the base 1, and the copper plate completely covers the placement groove 20, which facilitates subsequent monitoring of the sample addition process and prevents errors in sample addition.

[0250] The introduction of the autoregressive model includes the following poses:

[0251] Posture 1: From the simple pendulum system, let x t is the swing amplitude dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com