Preparation process of tea extract

A tea extract and preparation process technology, applied in the field of tea extract preparation, can solve the problems of loss of aroma components, low extraction efficiency, slow solvent reflux, etc., and achieve the effects of mild extraction process, bright color and easy batch amplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

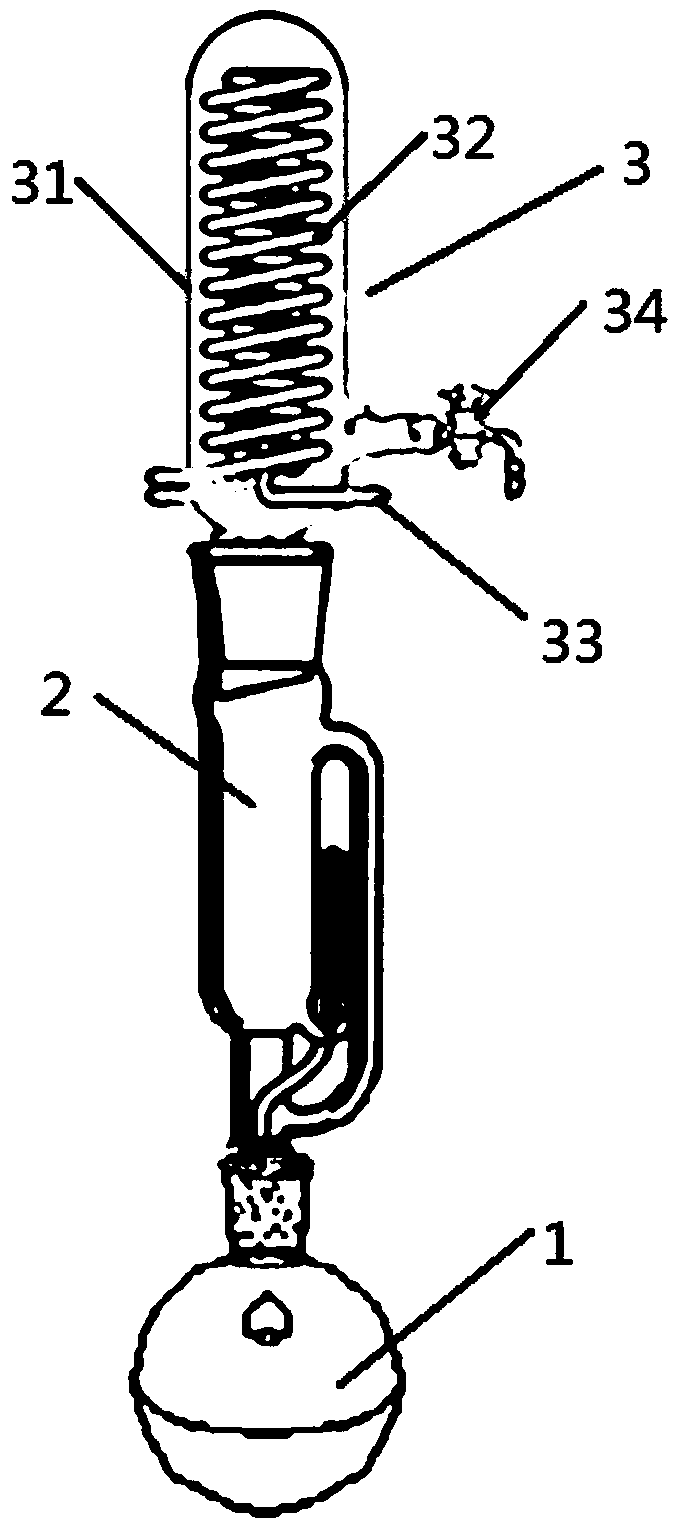

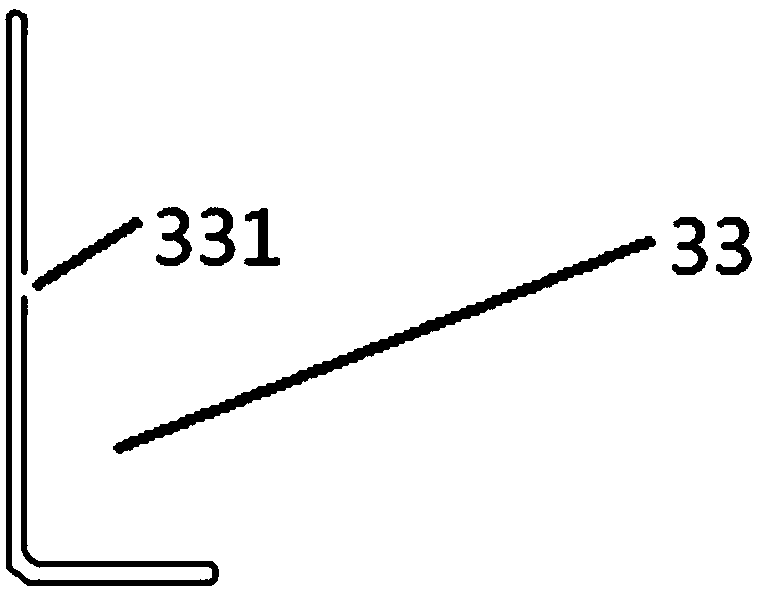

[0033] The present embodiment provides a kind of decompression Soxhlet extractor, and its structure schematic diagram is as follows figure 1 As shown, it includes a flask 1 for containing the extraction solvent, an extraction tube 2 and a condenser 3, the flask 1, the extraction tube 2 and the condenser 3 are connected in sequence, and the condenser 3 includes a shell 31 and a double-layer serpentine in the shell 31 The cooling liquid inlet and the cooling liquid outlet of the condensing coil 32 and the serpentine condensing coil 32 are located outside the shell; a vacuum pipe 33 is arranged inside the shell 31 and extends to the outside of the shell for connecting with a vacuum pump ( figure 2 ), the opening 331 of the vacuum pipe 33 inside the housing is located inside the serpentine condensing coil 32 . Vacuumizing pipeline 33 is an L-shaped pipeline ( figure 2 ), the vertical part of the L-shaped pipe is located inside the serpentine condensing coil. The L-shaped pipe ...

Embodiment 2

[0036] Weigh 15g of green tea powder, measure 300mL of 95% ethanol aqueous solution and 10ml of propylene glycol, stir and mix the three and soak for 4 hours, extract according to the decompression Soxhlet device designed in this patent, the extraction temperature is 50°C, and the cooling liquid temperature is set to -10℃~-15℃, the round-bottomed flask connected to the extractor is not stirred first, after the temperature, vacuum and condensation have reached and stabilized, the solvent begins to evaporate and be condensed, observe the dripping speed of the solvent after cooling, and then turn on the magnetic force Stir, the magnet rotates in the round-bottom flask, and then observe the drop rate of the solvent after cooling. The experiment shows that the drop rate of the solvent is obviously accelerated when the solvent is stirred. It shows that adding a stirring device to the round-bottomed flask, other conditions remain unchanged, can improve the solvent evaporation rate ver...

Embodiment 3

[0038] Weigh 15g of green tea powder, measure 300 mL of 95% ethanol aqueous solution and 10ml of propylene glycol, stir and mix the three and soak for 4 hours, extract according to the decompression Soxhlet device designed in this patent, extract for 1 hour, the extraction temperature is 50°C, and the cooling liquid temperature Set at -10°C to -15°C until the tea bag soaking liquid becomes light and almost colorless, take out the tea bag, put 15g of fresh tea bags into it and continue to extract for 1 hour until the tea bag soaking liquid becomes light and close to colorless. When the extract is collected, the color is green and bright, and it has a very pure green tea aroma, and the tea leaves have an obvious fragrance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com