Method for testing charging process

A charging process and charging station technology, which is applied to charging stations, testing electrical devices in transportation, measuring electricity, etc., can solve problems such as loss of testing time, prolonging inspection time, and increasing research and development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

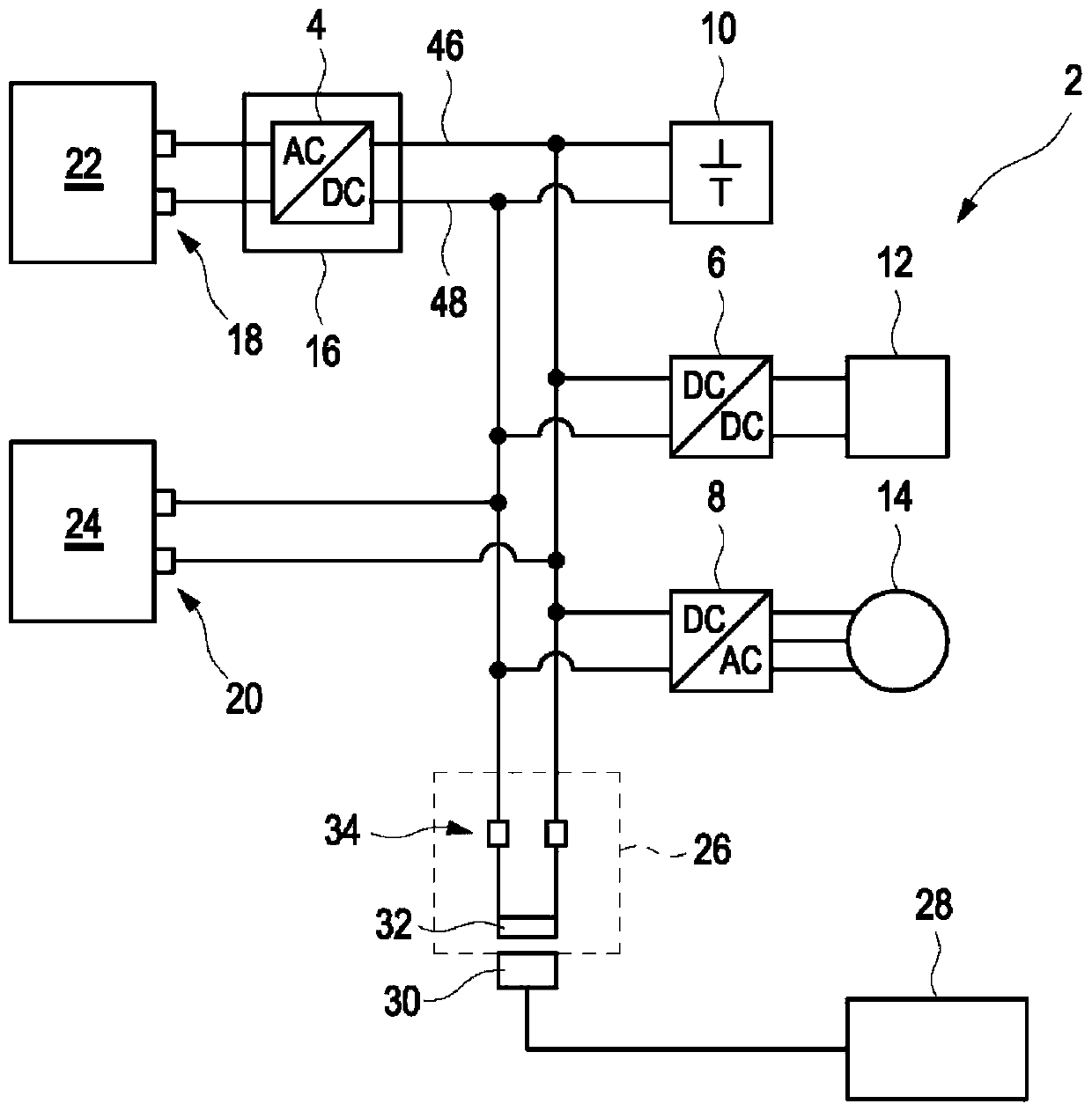

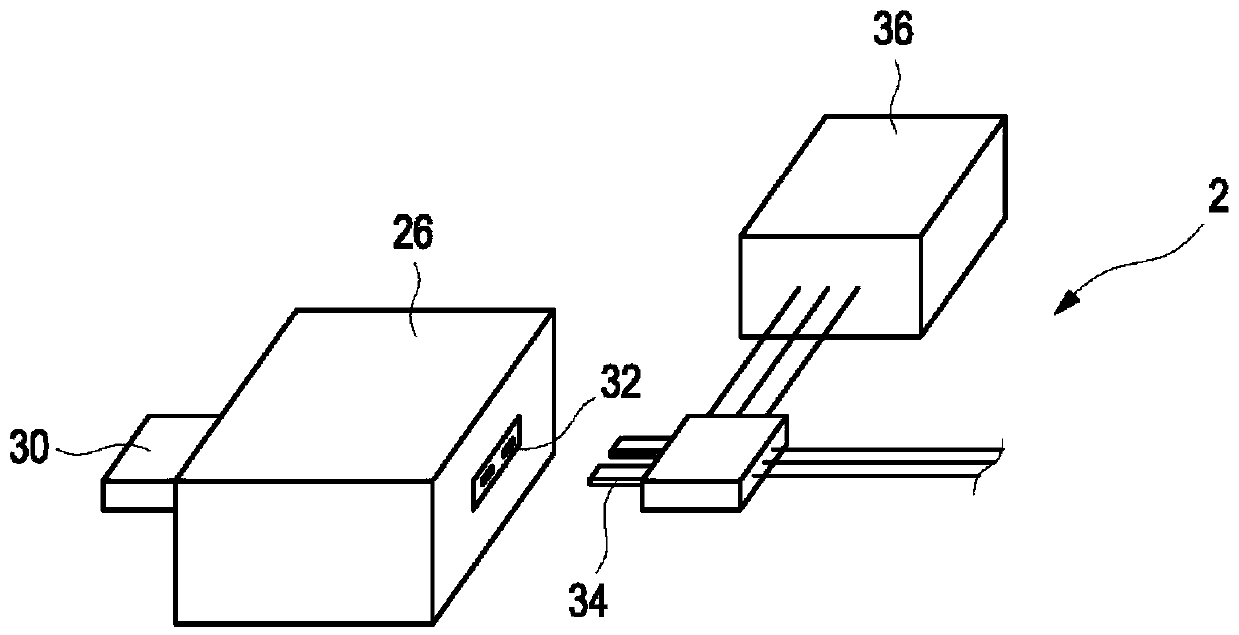

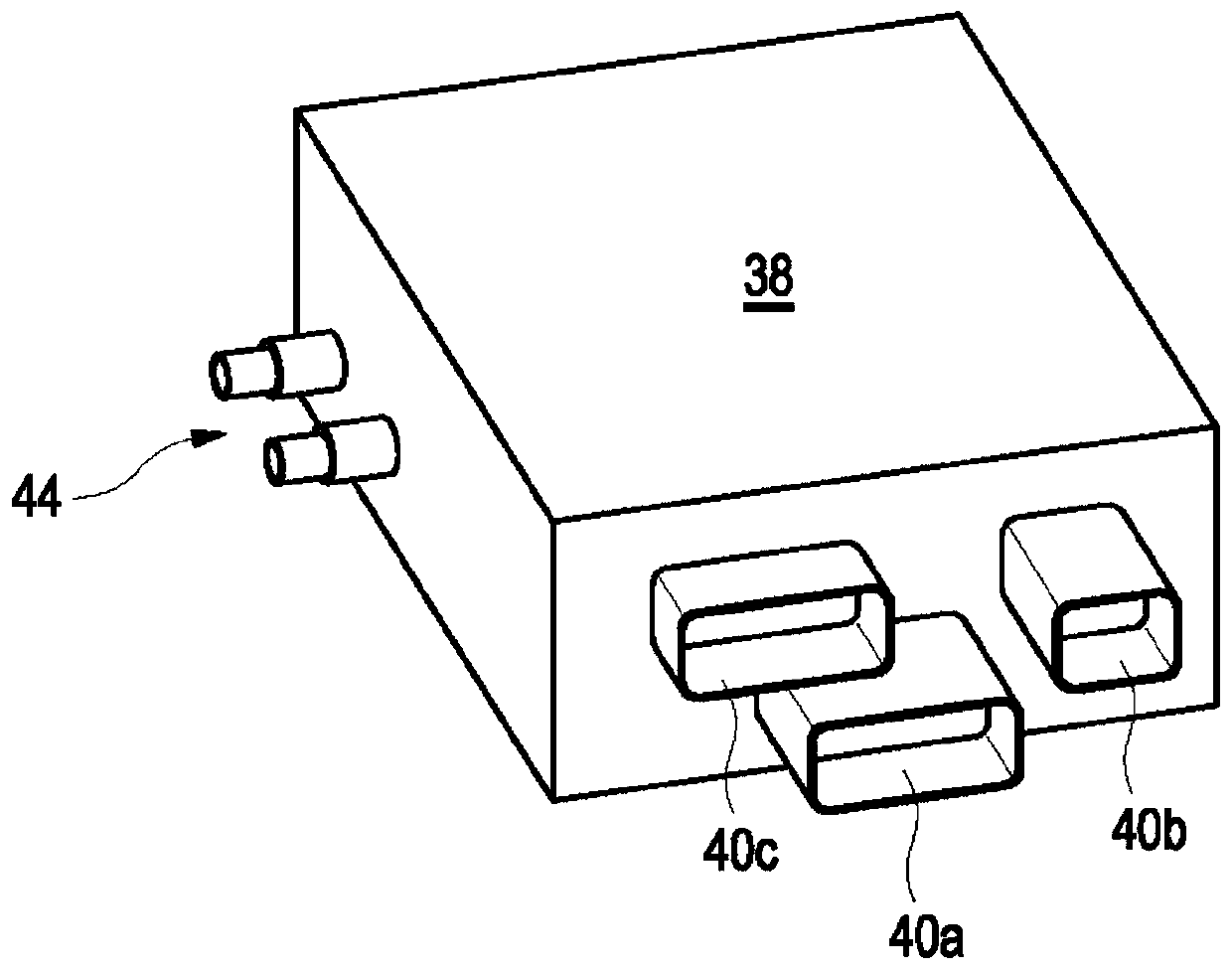

[0058] Figure 1a The schematic diagram shows an onboard electrical system 2 of a motor vehicle designed as a hybrid or electric vehicle, wherein the onboard electrical system 2 has a plurality of interconnected lines, in particular high-voltage lines, as components. Here, the first branch 46 comprises a plurality of interconnected lines for the positive high voltage (HV+), while the second branch 48 comprises a plurality of interconnected lines for the negative high voltage (HV−). As further components, the vehicle electrical system 2 has a first converter 4 , here an AC-DC converter; a second converter 6 , here a DC-DC converter; and a third converter 8 , here Designed as a DC-AC converter or inverter. An electrical energy store 10 or a corresponding battery, which is here designed as a high-voltage or high-voltage energy store, is connected to the vehicle electrical system 2 . At least one load 12 , for example an electrical device, is connected to vehicle electrical syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com