Easy-to-clean spraying-free polypropylene material and preparation method thereof

A polypropylene material, easy-to-clean technology, applied in the field of materials, can solve the problems of inability to melt, high melting point of polytetrafluoroethylene micropowder, appearance pitting, etc., to improve water contact angle, improve processing stability, and low equipment requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

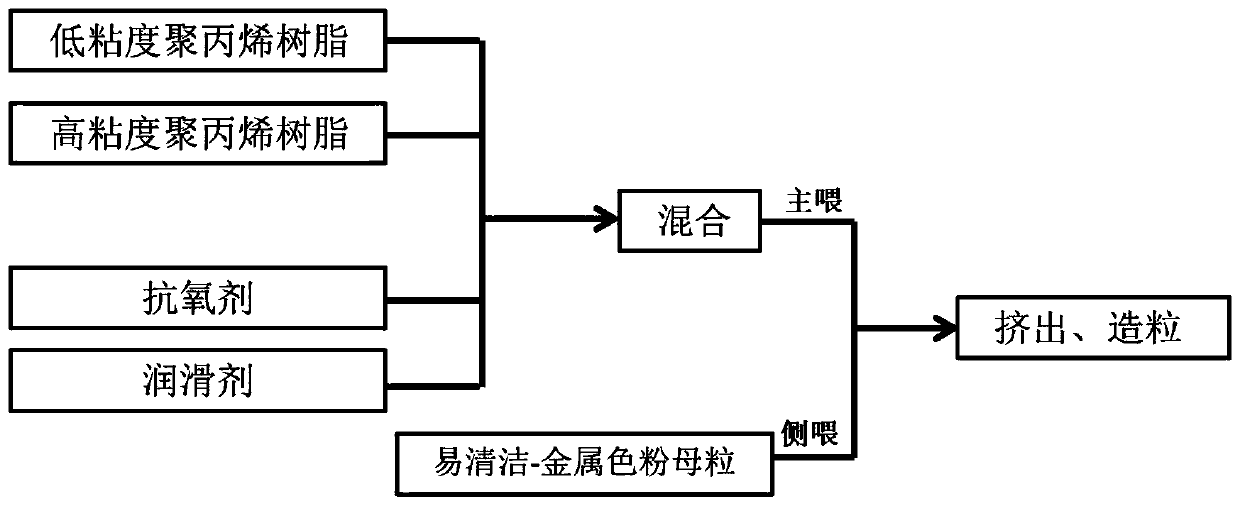

Method used

Image

Examples

Embodiment 1

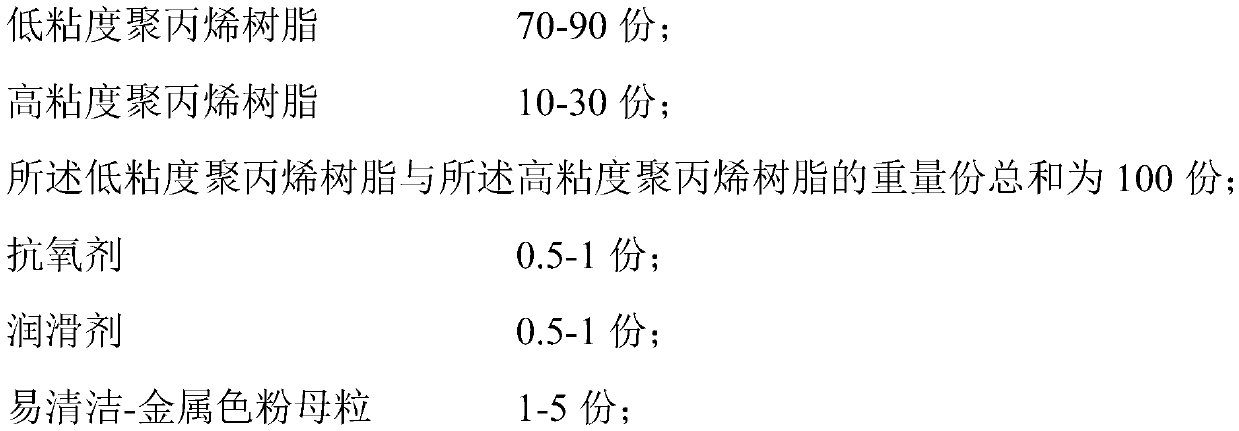

[0068] In this embodiment, an easy-to-clean and spray-free polypropylene material is prepared from the following raw materials by weight:

[0069]

[0070] Wherein, the preparation method of easy-to-clean-metallic toner masterbatch is as follows: 1) metal toner aluminum powder and trifluoropropyltriethoxysilane are mixed in a blender according to a mass ratio of 1:10, and the The rotation speed is 100r / min, and the mixing time is 1min; 2) According to the ratio of the total mass of the material to the polypropylene powder mass in step 1) of 1:1, continue to add polypropylene powder to the high mixer, and then continue to mix with the mixer, The rotation speed of the mixer is 100r / min, and the mixing time is 1min; 3) Add the mixed material in step 2) into the twin-screw extruder through side feeding, and then melt and extrude to granulate to obtain the easy-to-clean-metallic toner masterbatch . The process parameters of twin-screw extruder melt extrusion granulation are as ...

Embodiment 2

[0077] In this embodiment, an easy-to-clean and spray-free polypropylene material is prepared from the following raw materials by weight:

[0078]

[0079] Wherein, the preparation method of easy-to-clean-metallic color powder masterbatch is as follows: 1) metal color powder silver powder and trifluoropropyl trimethoxysilane are mixed in the mixer according to the ratio of 1:5 according to mass ratio, and the rotating speed of mixer is 200r / min, the mixing time is 2min; 2) according to the ratio of the total mass of the material to the polypropylene powder mass in step 1) of 1:1, continue to add polypropylene powder to the high mixer, and then continue to mix with the mixer. The rotation speed is 200r / min, and the mixing time is 2min; 3) The material mixed in step 2) is fed into the twin-screw extruder through side feeding, and then melted and extruded to granulate, and the easy-to-clean-metallic toner masterbatch is obtained. The process parameters of twin-screw extruder m...

Embodiment 3

[0085] An easy-to-clean spray-free polypropylene material, comprising the following components by weight:

[0086]

[0087] Among them, the preparation method of the easy-to-clean-metallic toner masterbatch is as follows: 1) Mix the metallic toner copper powder and all (17) fluorodecyltrimethoxysilane in a mixer according to the mass ratio of 1:1 , the rotating speed of the mixer is 300r / min, and the mixing time is 3min; 2) According to the ratio of the total mass of the material to the polypropylene powder mass in step 1) as 1:1, continue to add polypropylene powder to the high mixer, and then continue to use Mixing with a mixer, the speed of the mixer is 300r / min, and the mixing time is 3min; 3) Add the mixed material in step 2) into the twin-screw extruder through side feeding, and then melt and extrude to granulate, that is, the easy-to-clean-metallic color Powder masterbatch. The process parameters of twin-screw extruder melt extrusion granulation are as follows: the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com