Adsorbent and application thereof to wool dyeing wastewater recycling technology

A technology for dyeing wastewater and adsorbents, which is used in adsorption water/sewage treatment, textile industry wastewater treatment, water pollutants, etc., to achieve the effects of easy treatment, cost reduction, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

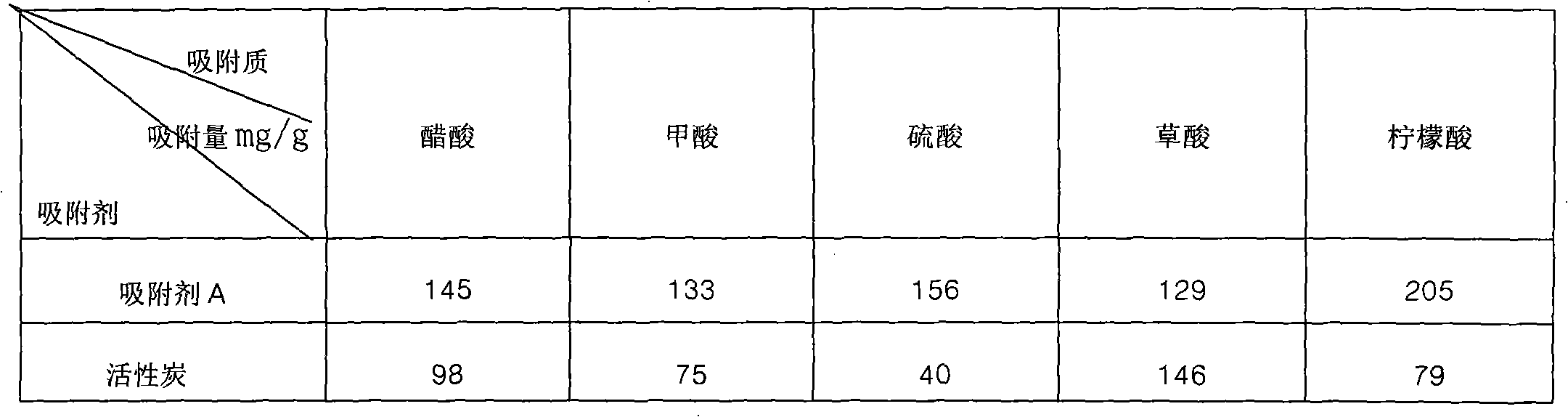

[0021] Embodiment 1: adopt the mode of operation in the summary of the invention (2), adsorbent A and 35 mesh activated carbons, adsorbent quality 1g, adsorbate initial concentration 0.2mol / L, under the condition of temperature 30 ℃, time 30 minutes, to acetic acid, Formic acid, sulfuric acid, oxalic acid, and citric acid were adsorbed, and the results are shown in Table 1.

[0022] Table 1 Adsorption of acid by adsorbent A and 35 mesh activated carbon

[0023]

Embodiment 2

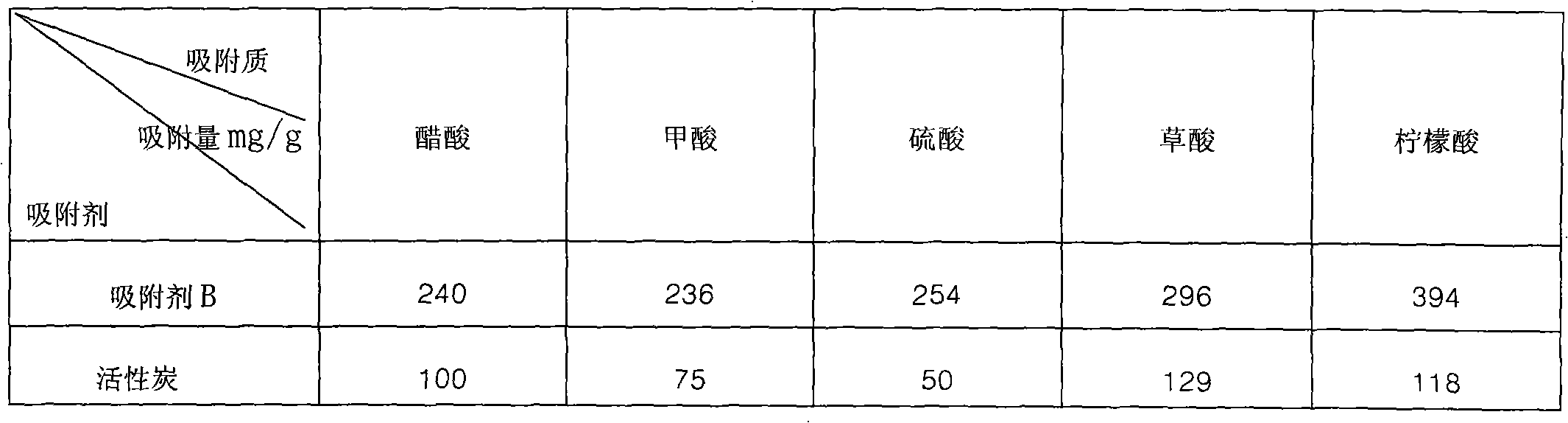

[0024] Embodiment 2: adopt the mode of operation in the content of the invention (2), adsorbent B and 120 mesh activated carbon, adsorbent quality 1g, adsorbate initial concentration 0.2mol / L, under the condition of temperature 30 ℃, time 30 minutes, to acetic acid, Formic acid, sulfuric acid, oxalic acid, and citric acid were adsorbed, and the results are shown in Table 2.

[0025] Table 2 Adsorption of acid by adsorbent B and 120 mesh activated carbon

[0026]

Embodiment 3

[0027] Embodiment 3: Adopt the mode of operation in the summary of the invention (2), adsorbent A, adsorbent mass 50g, initial concentration of adsorbate 0.4mol / L, under the condition of temperature 30 ℃, time 30 minutes, adsorbent A to acetic acid The adsorption capacity is 143 mg / g, the adsorption capacity for formic acid is 125 mg / g, the adsorption capacity for sulfuric acid is 154 mg / g, the adsorption capacity for oxalic acid is 108 mg / g, and the adsorption capacity for citric acid is 200 mg / g.

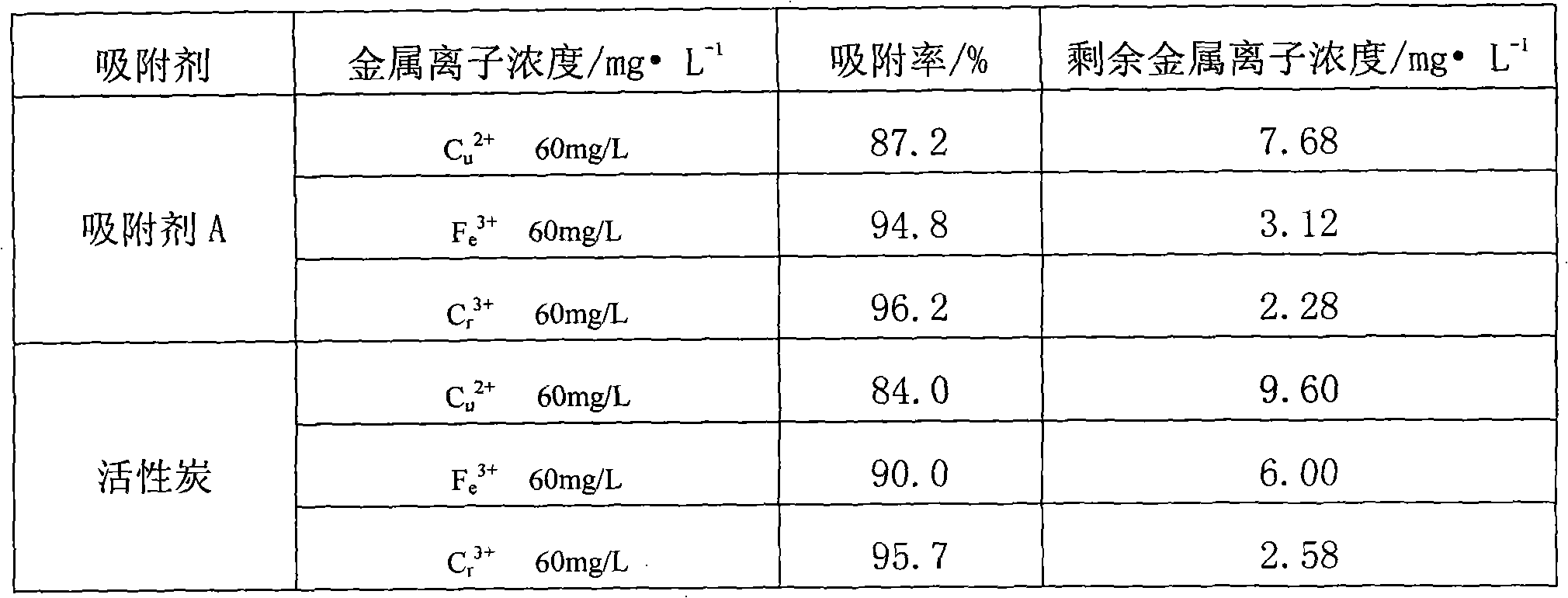

[0028] The data of embodiment 1-2 shows: adsorbent A and B are to the adsorption capacity of above-mentioned several acids greater than 50%-400% of the adsorption capacity of activated carbon to corresponding acid; High-quality adsorbents readily available at low cost.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com