High-conductivity soft aluminum monofilament with good heat resistance and preparation method thereof

A technology with high conductivity and heat resistance, applied in the direction of conductive materials, conductive materials, cable/conductor manufacturing, etc., can solve the problems that heat resistance cannot meet the needs of power grid construction and development, and achieve excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

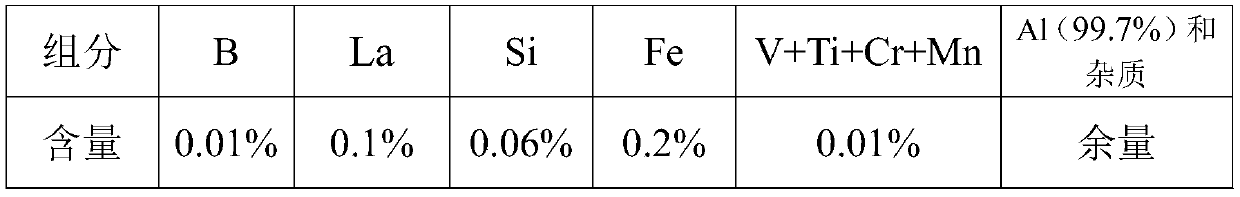

[0041] The components of the high-conductivity soft aluminum monofilament with good heat resistance provided in this example are shown in Table 1, and the preparation parameters and properties are shown in Table 2:

[0042] Table 1. Mass percentage of each component

[0043]

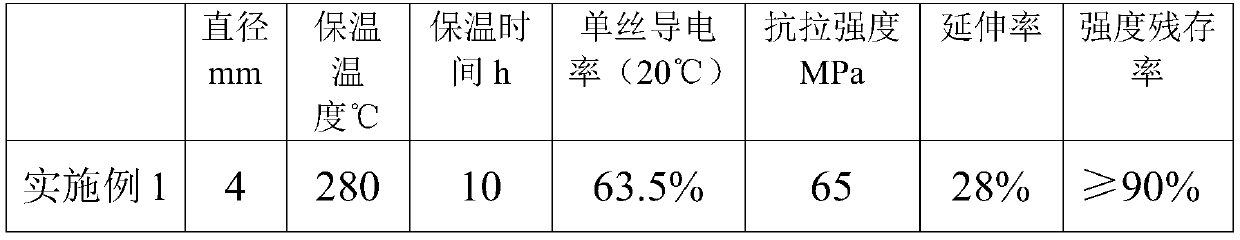

[0044] Table 2. Preparation process parameters and properties

[0045]

[0046] Among them, the strength residual rate after heat preservation at 230° C. for 1 hour is ≥90%, which proves that the heat resistance of this example is excellent.

Embodiment 2

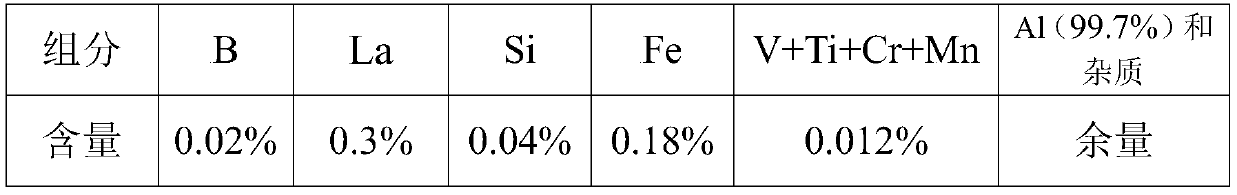

[0048] The components of the high-conductivity soft aluminum monofilament with good heat resistance provided in this example are shown in Table 3, and the preparation parameters and properties are shown in Table 4:

[0049] Table 3. Mass percentage of each component

[0050]

[0051] Table 4. Preparation process parameters and properties

[0052]

[0053] Among them, the strength residual rate after heat preservation at 230° C. for 1 hour is ≥93%, which proves that the heat resistance of this example is excellent.

Embodiment 3

[0055] The components of the high-conductivity soft aluminum monofilament with good heat resistance provided in this example are shown in Table 5, and the preparation parameters and properties are shown in Table 6:

[0056] Table 5. Mass percentage of each component

[0057]

[0058] Table 6. Preparation process parameters and properties

[0059]

[0060] Among them, the strength residual rate after heat preservation at 230° C. for 1 hour is ≥92%, which proves that the heat resistance of this example is excellent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com