Dry paper pulp production method

A production method and pulp technology, applied in pulp beating methods, chemical instruments and methods, papermaking, etc., can solve the problems of high pulp prices, waste paper mixed with other garbage, and failure to pass customs inspections, etc., to achieve small investment and high production efficiency. The effect of short process and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Embodiment: a kind of dry pulp production method.

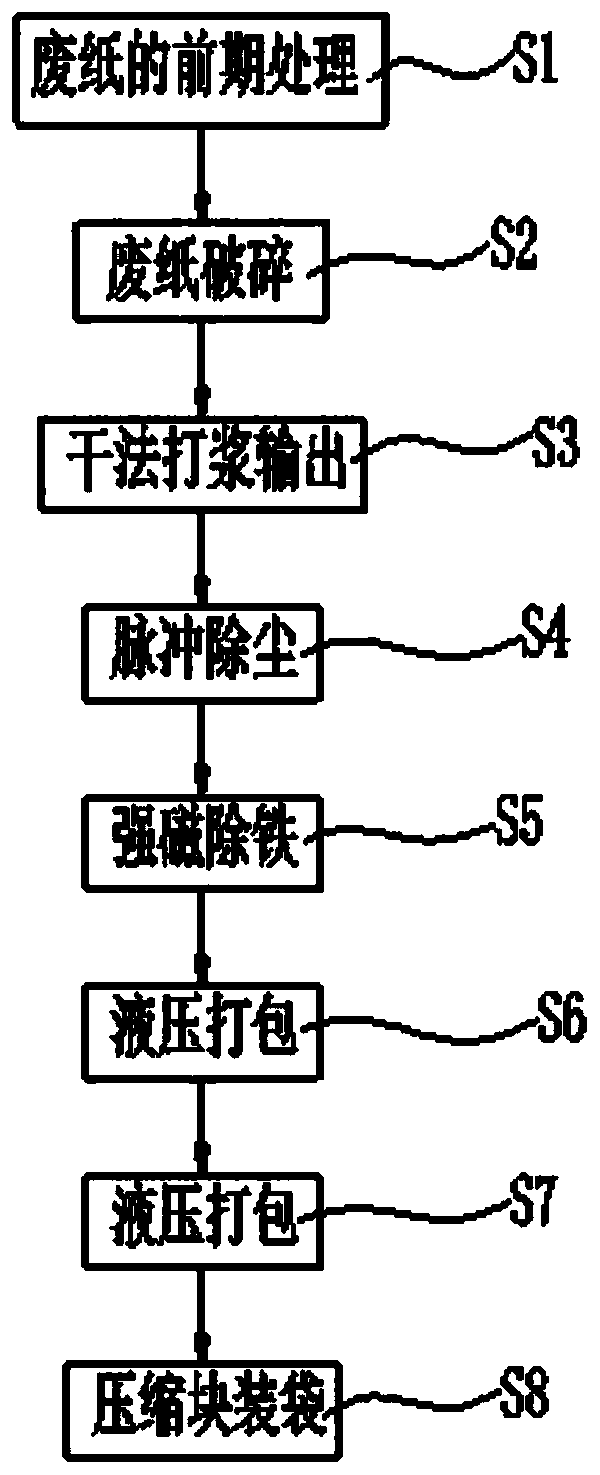

[0036] refer to Figure 1 to Figure 8 Shown, a kind of dry pulp production method specifically comprises the steps:

[0037] S1. Pre-treatment of waste paper. After the waste paper is transported to the factory for weighing, it is transported to the manual sorting area by a forklift, and the large impurities such as gummed paper and metal in the waste paper are removed by manual sorting.

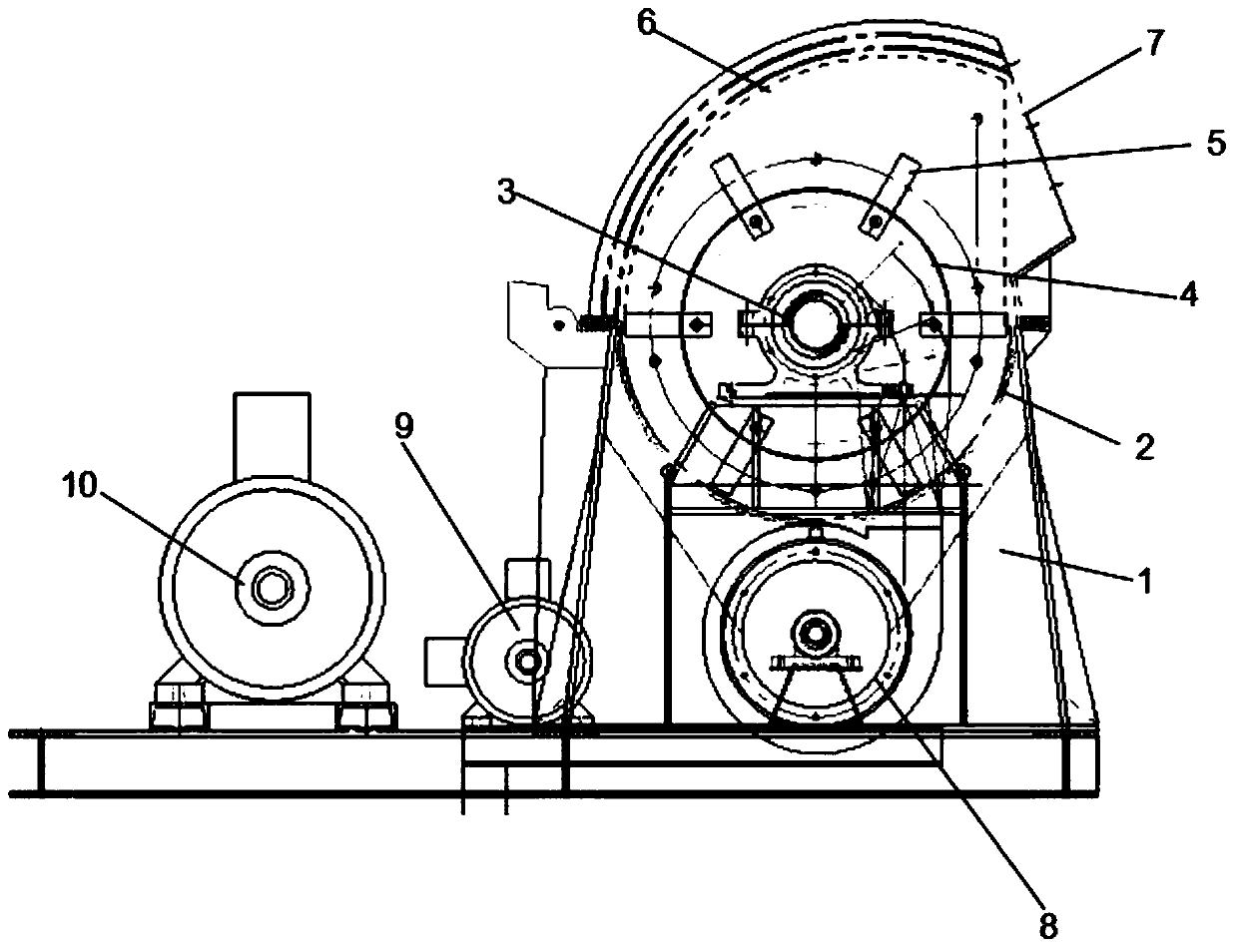

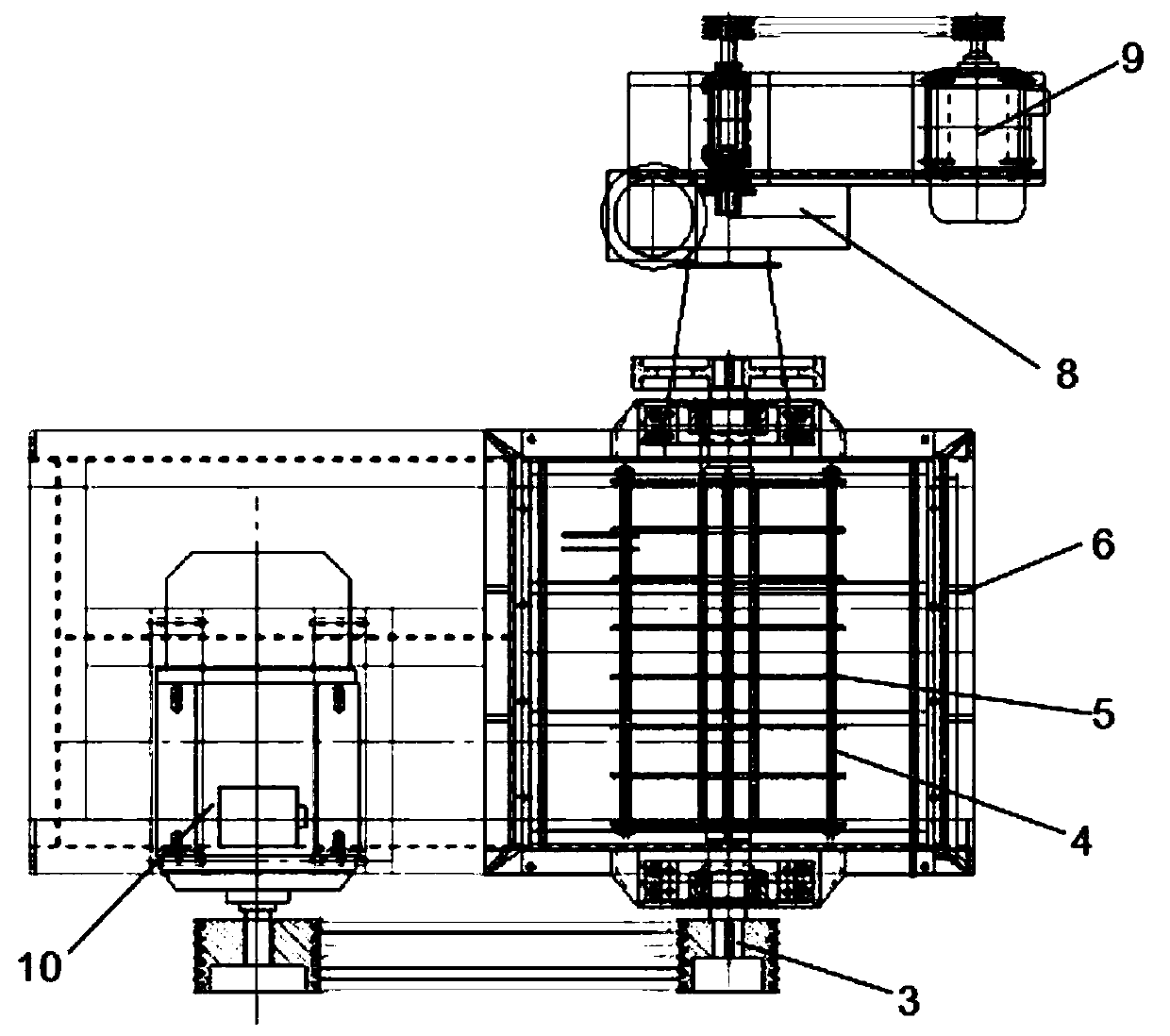

[0038] S2. Waste paper shredding. Use a waste paper shredder to preliminarily shred the waste paper, so that the waste paper decomposes into fluffy fluffy pieces. In this embodiment, the waste paper shredder is designed by itself. figure 2 and image 3 As shown, the waste paper shredder includes a frame 1, a crushing cylinder 2 is installed on the frame 1, a crushing roller 4 is installed in the crushing cylinder 2, and crushing knives 5 are uniformly installed on the crushing roller 4 A cover 6 is installed above the crushing roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com