Water stop structure applied to concrete foundation construction and construction method

A construction method and concrete technology, which is applied in the direction of infrastructure engineering, protection devices, buildings, etc., can solve the problems of not being able to ensure the high cost of middle telescopic balls, steel plates and supporting components, and not being able to firmly fix waterstops, etc. Achieve the effect of simple structure preparation and assembly, improve labor productivity, and light overall material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

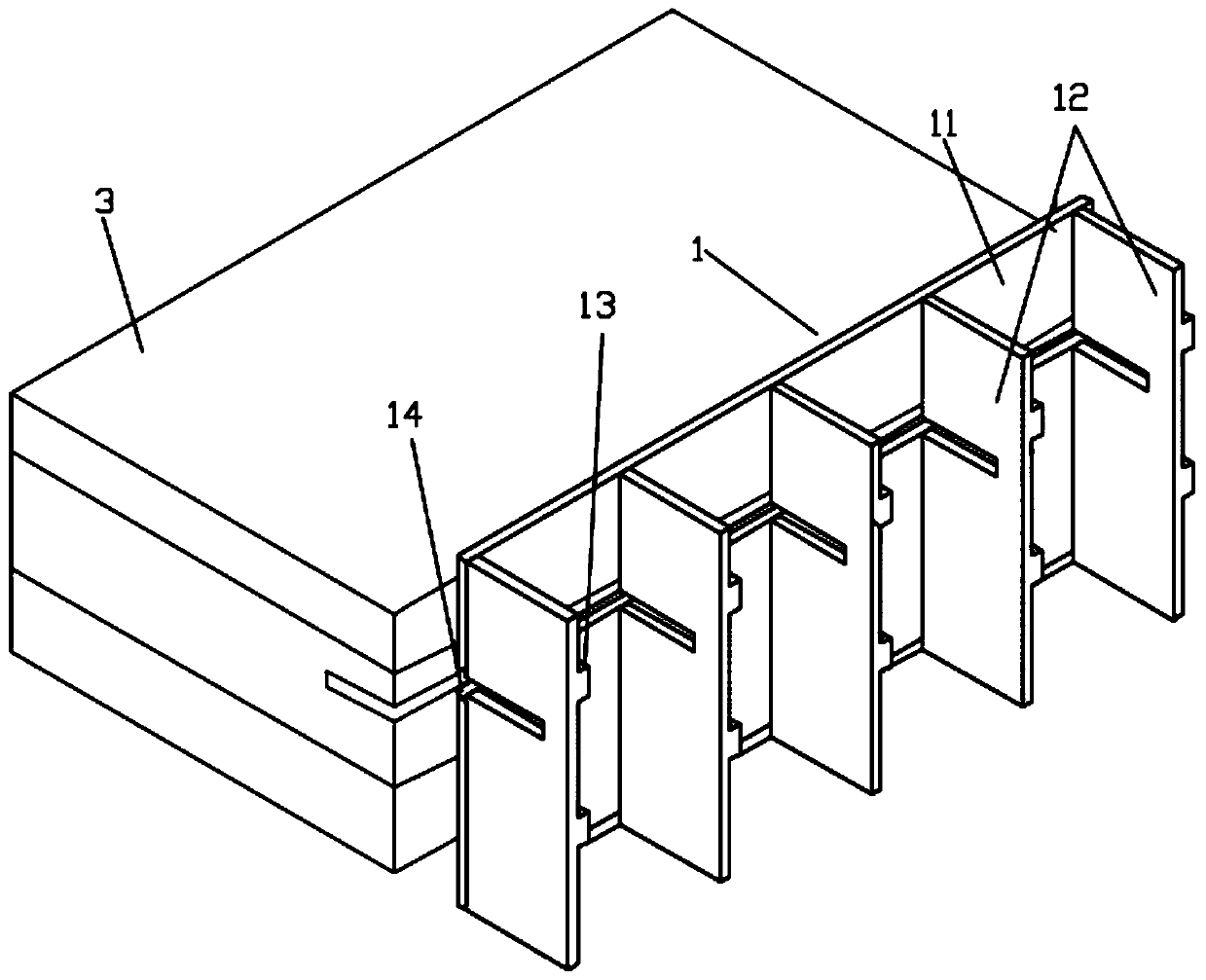

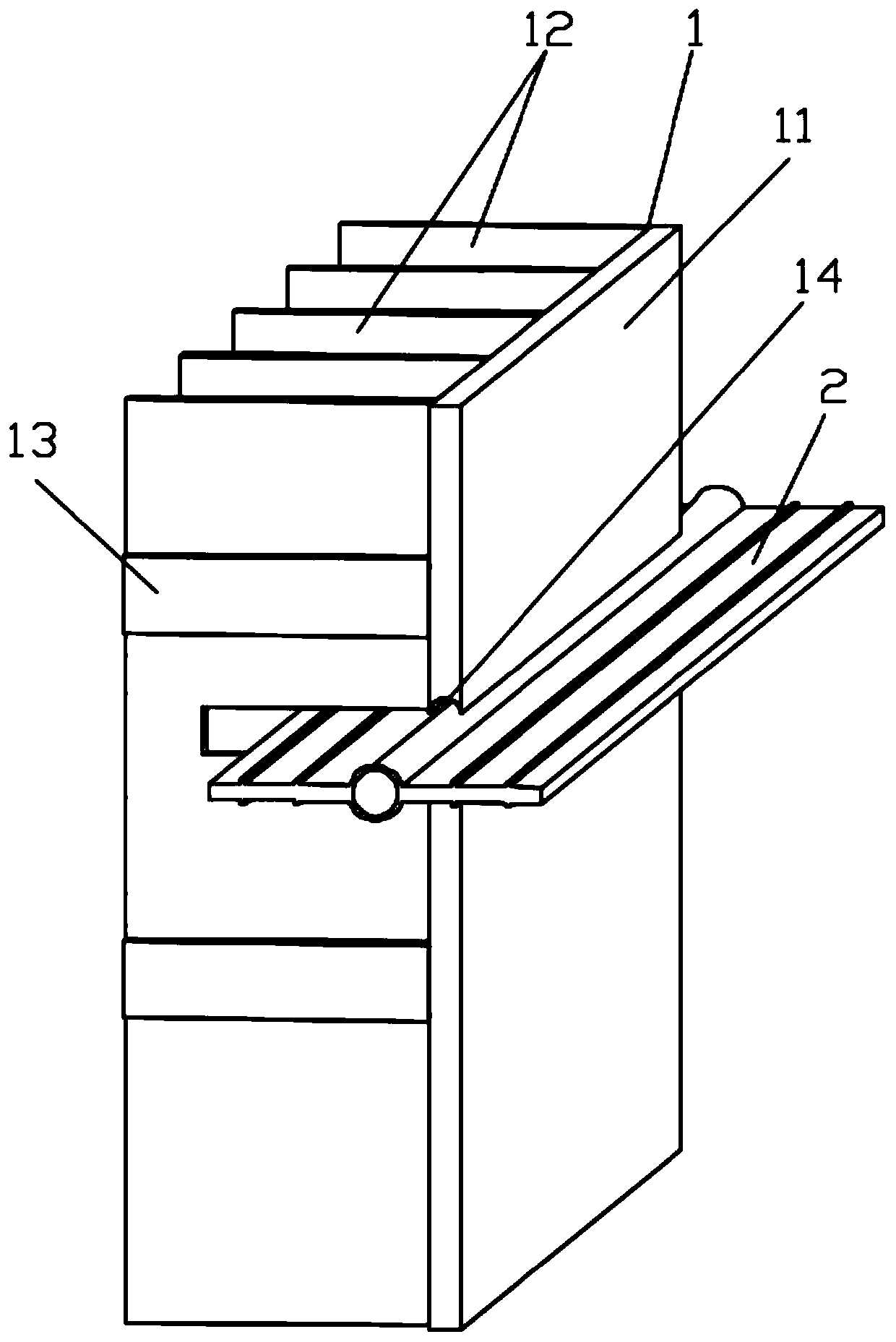

[0029] A water stop system construction method for concrete foundation construction, the construction method mainly includes steps:

[0030] 1) Determine the position of the expansion joint: Before binding the steel bars and pouring the concrete, pop up the positioning line of the expansion joint between the cushion and the reinforced concrete to determine the position of the expansion joint;

[0031] 2) Positioning of the waterstop: When the installation of the steel bars is completed, install the waterstop at the predetermined expansion joint position, and insert it from one long side of the waterstop to the Bottom reinforcement and surface reinforcement Bending notches;

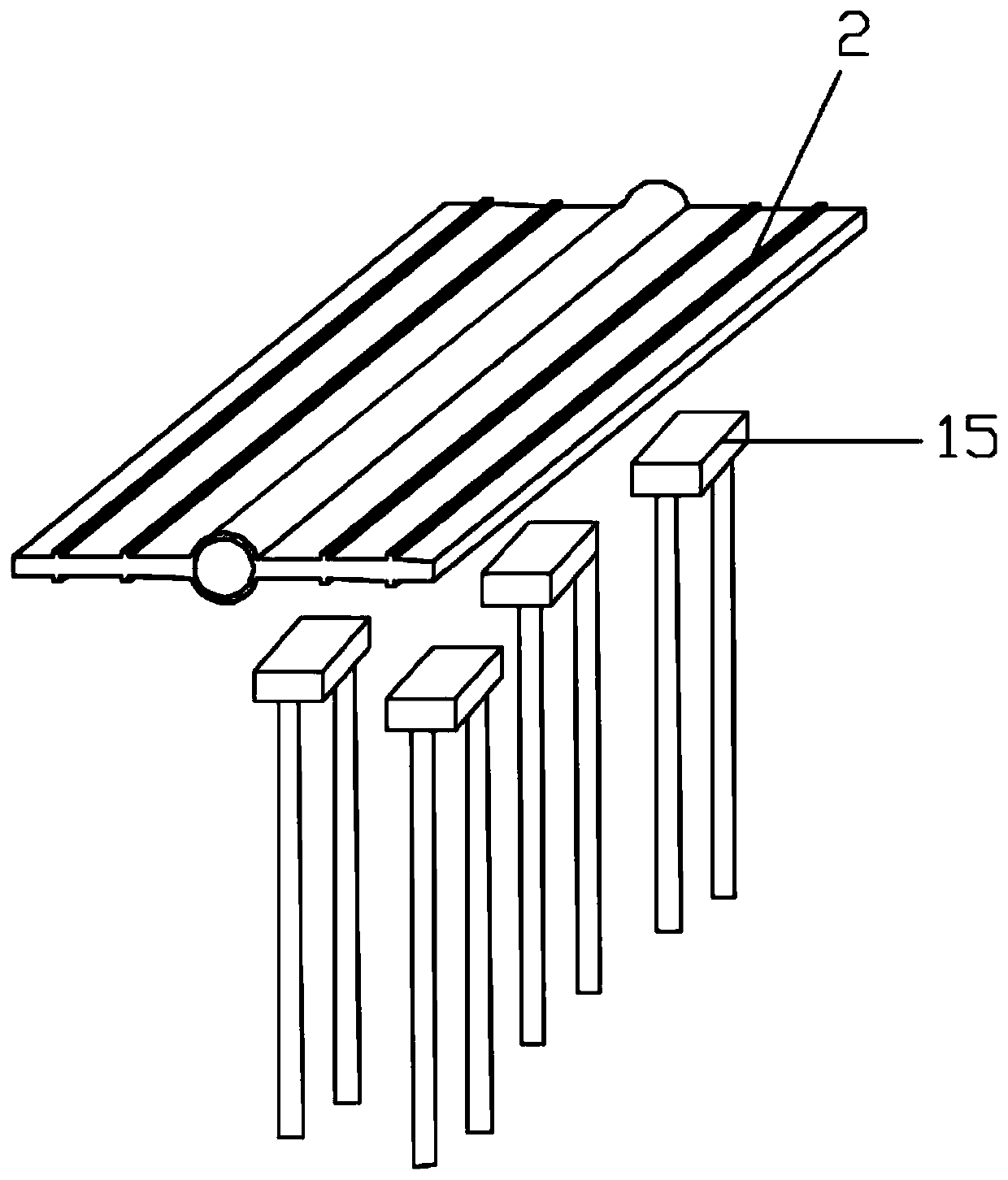

[0032] 3) Install the fixed pads 15: install shaped steel bars on both sides of the waterstop in the vertical direction to support the waterstop through the shaped steel bars, and at the same time bind several fixed pads 15 at intervals on the top of the shaped steel bars and pass the fixed pads 15 Suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com