Preparation method of thin composite nano-scale coating

A flake and nano technology, applied in the field of preparation of thin composite nano flake coatings, can solve the problems affecting the application of nano flake coatings, the coating cannot be made too thin, and the protective performance of the coatings is reduced, and achieves good lamination labyrinth effect, excellent adhesion and so on. The effect of focusing on and eliminating internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] A preparation method of thin composite nano-scale coating, the preparation method is as follows:

[0054] (1) Choose resin base material, described resin base material comprises epoxy resin base material, epoxy phenolic resin base material, polyphenylene sulfide resin base material, polyurethane resin base material, polyfluorine resin base material, fluorocarbon One or more of resin base material, acrylic base material, chlorinated rubber base material, perchlorethylene base material, alkyd base material.

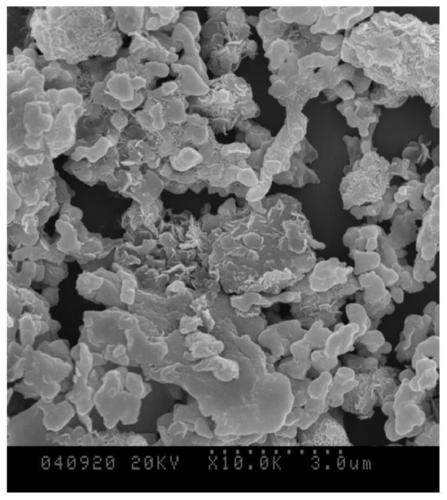

[0055] Composite nano-scale materials are selected, the composite nano-scales have a thickness of 1-40nm, and the size of the planar direction of the sheet is 0.2-50 μm; it is uniform, active, multi-functional, highly dispersed, fully chemically bonded with the compounding agent, The one-dimensional composite nano-scale material coated with a protective agent is not only an active filler of a paint, but also a modifier and a coupling agent.

[0056] Selection of add...

preparation Embodiment 1

[0134] In this example, nanoscale flakes composited with PTFE and graphene are prepared. The primary grinding uses a batch planetary ball mill, and the composite uses a continuous planetary ball mill. The main basic materials processed are 100 mesh PTFE powder and auxiliary basic materials. Multilayer graphene , the grinding ball is zirconia ball, the coupling agent, anti-settling agent, dispersant, protective agent and solvent are 3-(methacryloyloxy)propyltrimethoxysilane (KH-570), styrylphenol Polyoxyethylene ether, dimethylhydrochlorosilane, vinyl acetate, deionized water.

[0135] 1. Weigh 100g of the main base material PTFE, 50g of the auxiliary base material multilayer graphene, 3g of 3-(methacryloyloxy)propyltrimethoxysilane (KH-570), 3g of styrylphenol polyoxyethylene Vinyl ether 4.5g, vinyl acetate 3g, deionized water 60g.

[0136] 2. For the intermittent planetary ball mill, five specifications of zirconia balls are selected (13 / 16)"; (19 / 32)"; (3 / 8)"; (5 / 16)"; (7 / 3...

preparation Embodiment 2

[0142] In this example, iron and cobalt composite nanoscale flakes are prepared. The primary grinding uses an intermittent planetary ball mill, and the composite uses a continuous planetary ball mill. The main basic material processed is 200-mesh iron powder and the auxiliary basic material 300-mesh cobalt powder. The grinding balls are steel balls. The agent, protective agent and solvent were triethanolamine; sodium hexametaphosphate; deionized water.

[0143] 1. According to the main basic material iron powder 100g; the auxiliary basic material cobalt powder 100g; triethanolamine 10g; sodium hexametaphosphate 1g; water 200g for ingredients.

[0144] 2. For the intermittent planetary ball mill, five specifications of zirconia balls are selected (13 / 16)"; (19 / 32)"; (3 / 8)"; (5 / 16)"; (7 / 32) ". According to the volume of the ball mill work cylinder, the weights of various steel balls are (13 / 16)"350g; (19 / 32)"160g; (3 / 8)"110g; (5 / 16)"20g; (7 / 32) "20g.

[0145] 3. Put it into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com