Water-based internal drag-reducing epoxy coating for pipelines and its preparation method, anti-corrosion coating, and application

A technology for drag-reducing rings and pipes, applied in epoxy resin coatings, pipeline anti-corrosion/rust protection, anti-corrosion coatings, etc., can solve the problem of reducing the corrosion resistance of cross-linking density coatings and reducing the cross-linking density of water-based epoxy coatings , Affect the adhesion between the coating and the substrate, etc., to achieve the effect of improving adhesion, improving cathodic disbonding resistance, and improving anti-corrosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

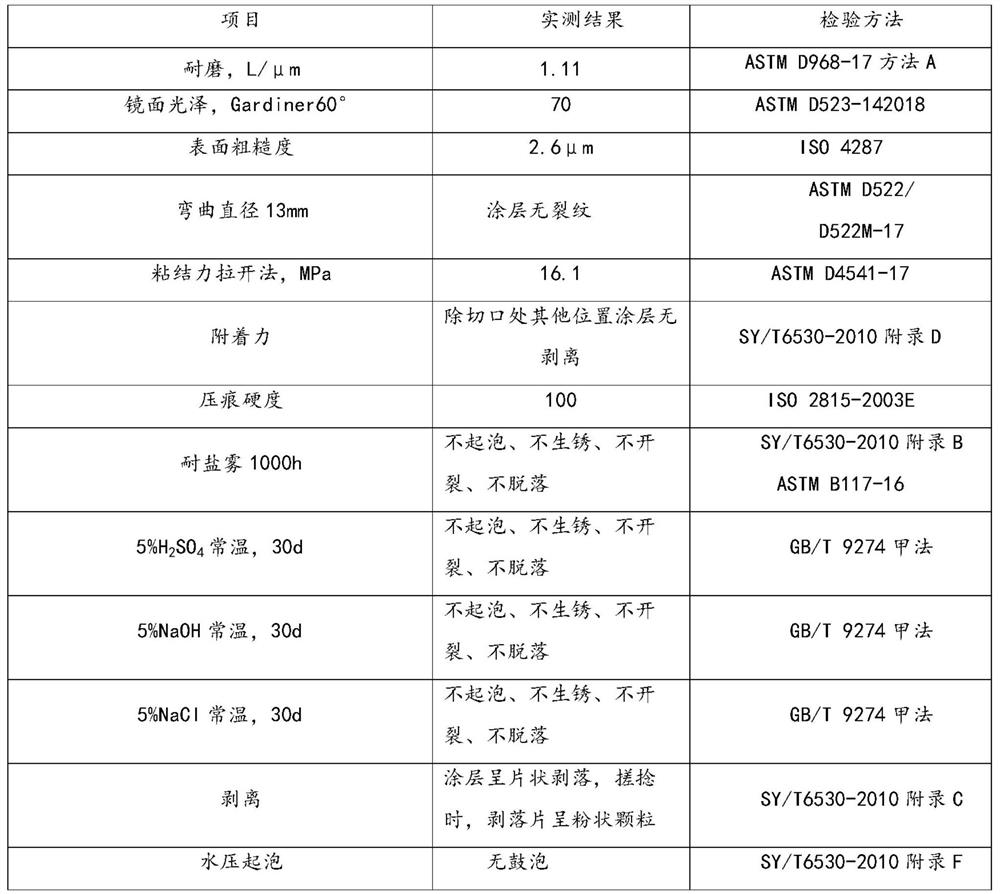

Embodiment 1

[0095] In the present embodiment, the steps of the manufacturing method of the drag-reducing epoxy coating in the water-based pipeline are as follows, and the ratio of each component is parts by weight:

[0096] Step 1, mix 0.5 parts of deionized water, 0.02 parts of AFCONA2501 defoamer, 0.03 parts of BYK181 dispersant, 0.02 parts of BYK333 wetting and leveling agent, 0.02 parts of synthro-cor C E660 B anti-flash rust agent, 0.02 parts of COATOSIL MP200 silane After mixing the coupling agent and 0.02 part of Densil P fungicide, stir at room temperature, add 0.6 part of barium sulfate, 0.5 part of micaceous iron oxide ash, 0.4 part of zinc aluminum phosphate, 0.008 part of clay, and 0.01 part of modified graphite while stirring Alkene and 0.1 part of modified nano-SiO 2 , continue to stir at high speed for 1 hour, so that the components are uniformly dispersed, and water slurry is obtained;

[0097] Step 2, mixing 1 part of water-based epoxy resin emulsion with the obtained wa...

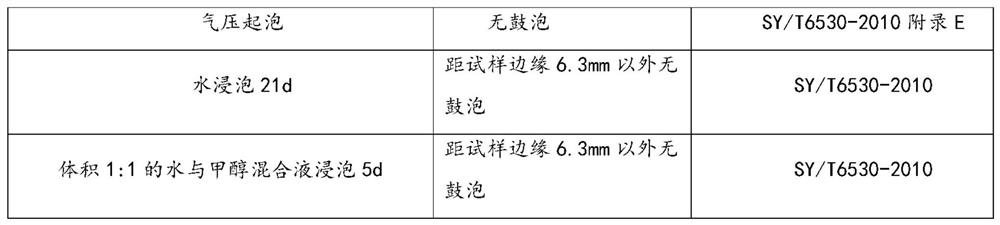

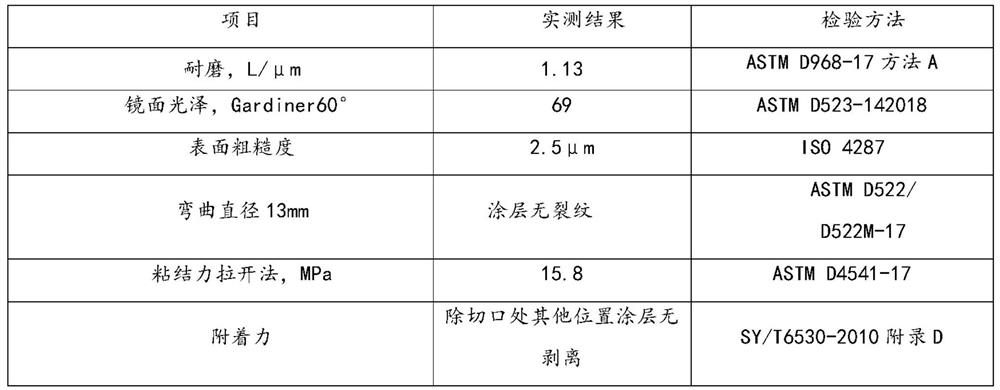

Embodiment 2

[0105] The manufacture method step of the drag-reducing epoxy coating in the water-based pipeline of present embodiment 2 is as follows, and the ratio of each component is parts by weight:

[0106] Step 1, add 0.5 parts of deionized water, 0.02 parts of AFCONA2505 defoamer, 0.03 parts of AFCONA5065 dispersant, 0.02 parts of BYK378 wetting and leveling agent, 0.02 parts of anti-flash rust agent 9079, 0.02 parts of COATOSIL MP200 silane coupling agent, 0.02 parts 1 part of Densil ZOD bactericide was mixed and stirred at normal temperature, and 0.5 part of barium sulfate, 0.6 part of micaceous iron oxide ash, 0.5 part of zinc aluminum phosphate, 0.009 part of pottery clay, 0.01 part of modified graphene and 0.1 part of modified Nano-SiO 2 , continue to stir at high speed for 1 hour, so that each component is dispersed evenly, and a water slurry is obtained;

[0107]Step 2, mixing 1 part of water-based epoxy resin emulsion with the obtained water slurry and stirring evenly, and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com