Steel-side-rib light shock-resistant energy-saving wallboard and construction method thereof

A steel edge and wall panel technology, which is applied in the field of earthquake-resistant energy-saving wall panels and their construction, can solve the problems of difficult installation of snap-in fasteners, difficulty in leveling the panels, and lack of integrity, so as to achieve an even appearance and easy alignment of the panels The effect of leveling and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Examples see Figure 1-6 as shown,

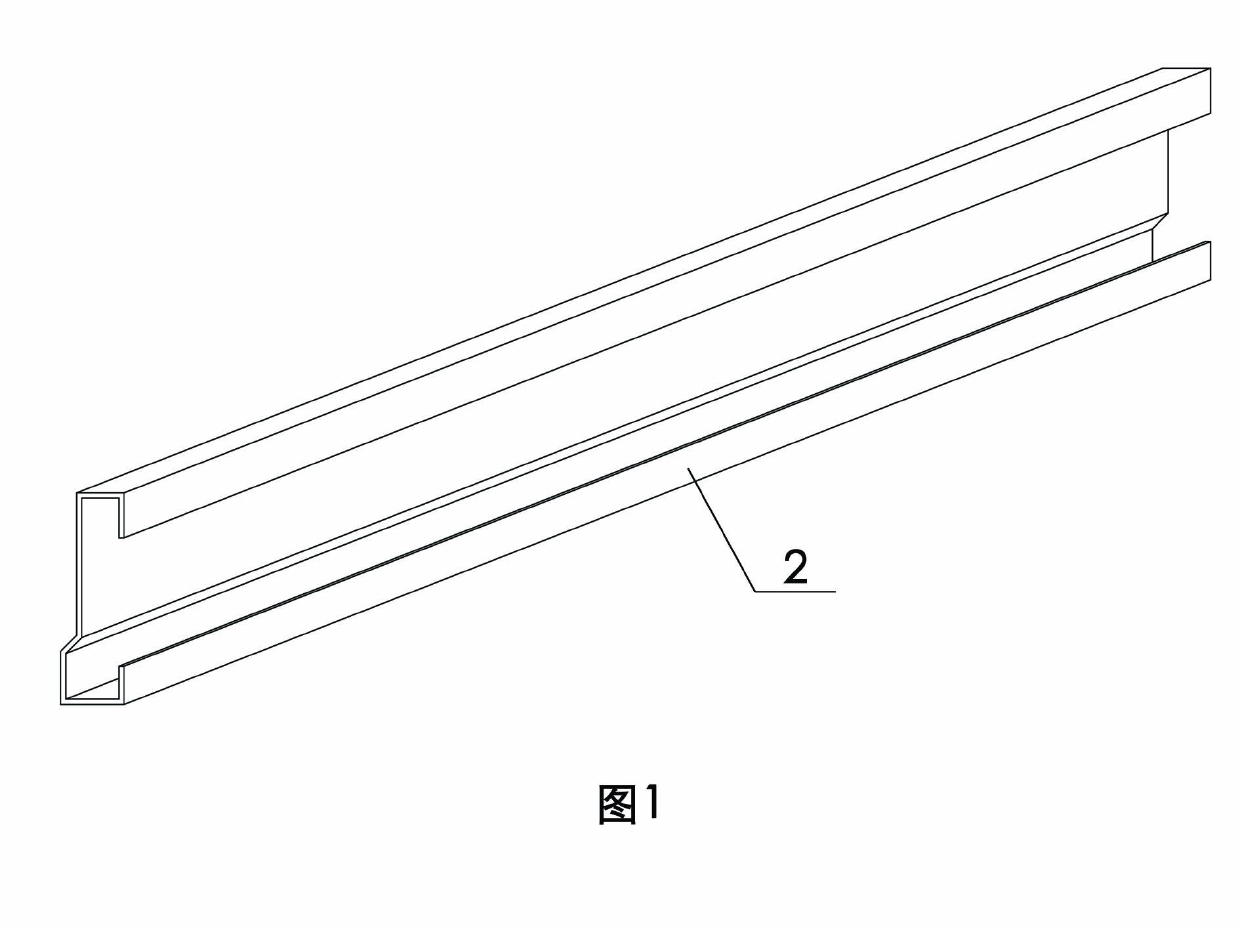

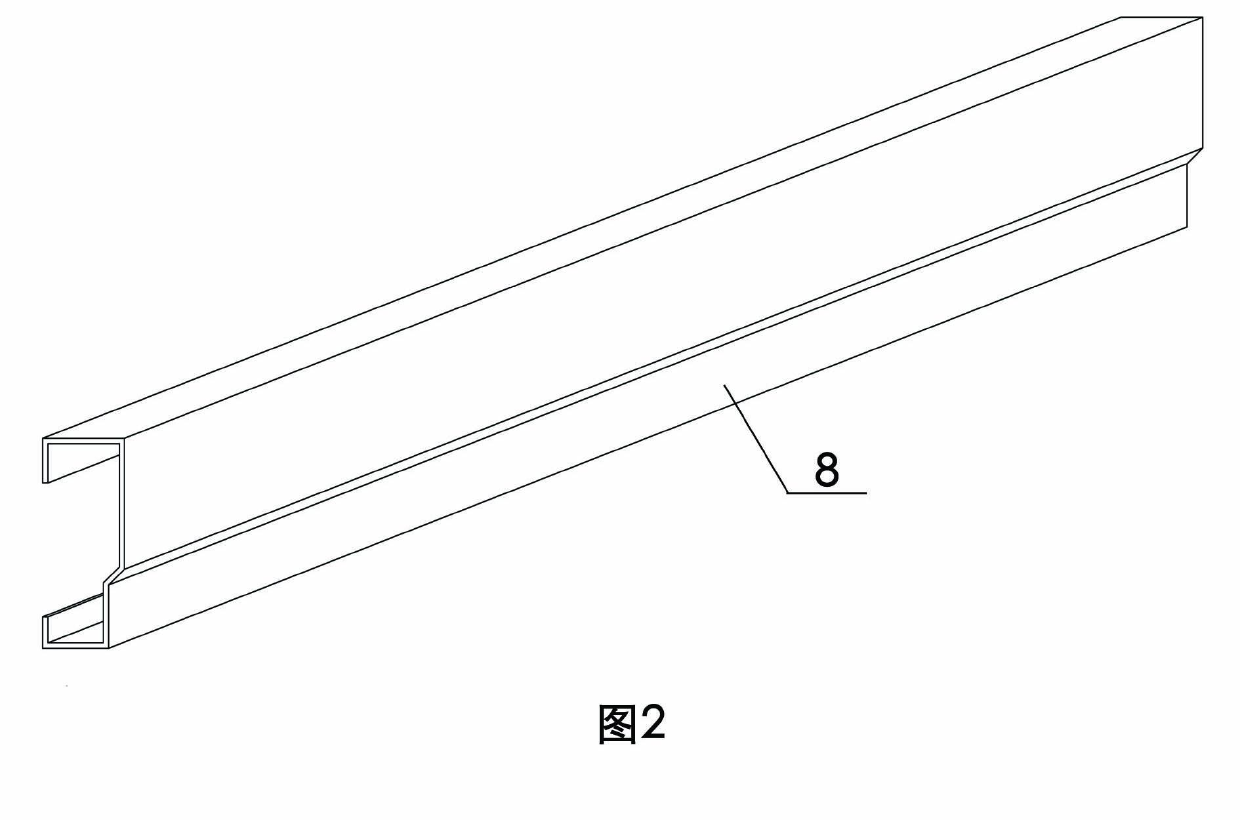

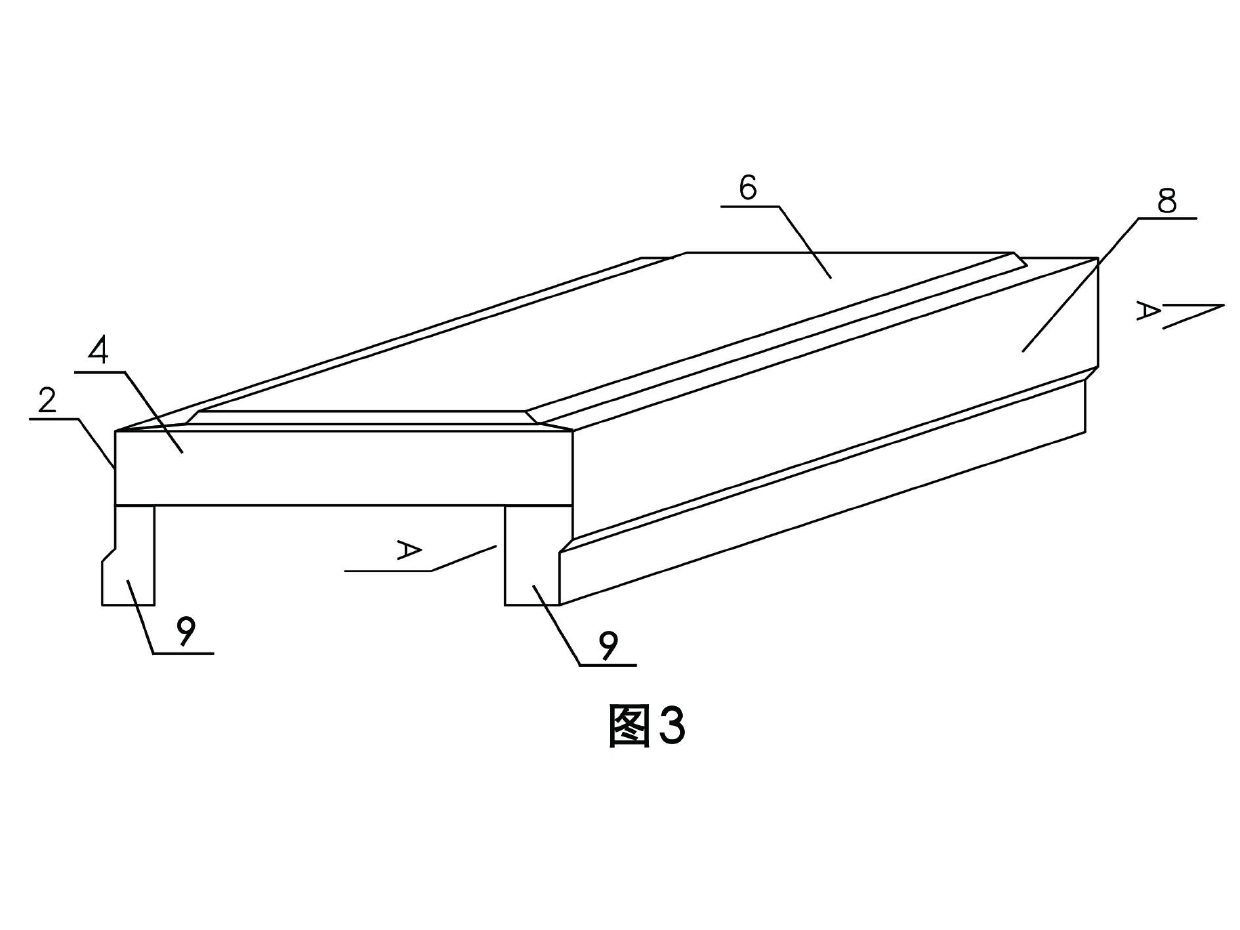

[0038] A light-weight anti-seismic energy-saving wall panel with steel ribs, comprising a reinforced concrete panel 1, the reinforced concrete panel 1 is formed by consolidation of lightweight concrete and steel wire mesh 5, and the surrounding protection of the reinforced concrete panel 1 There are steel side ribs, the steel side ribs are formed by connecting the left rib 2, two end ribs 4 and the right rib 8 end to end, the end rib 4 is arranged along the short side of the plate body 1, the left rib 2 and the right side Rib 8 is arranged along the long side of plate body 1, and described left rib 2 is " "Type, the right rib 8 is " ” type, the shapes of the two fit each other.

[0039] Stiffening ribs 3 parallel to the end ribs 4 are arranged at intervals between the end ribs 4 , and the ends of the stiffening ribs 3 are connected with the left rib 2 and the right rib 8 .

[0040] The left rib 2 and the end rib 4, the right ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com