Beam column or beam-beam butt joint node structure suitable for assembly type PEC and construction method thereof

A joint structure and assembly technology, which is applied in the direction of building structure and construction, can solve the problems of easy slurry leakage pollution, easy corbels, and high construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

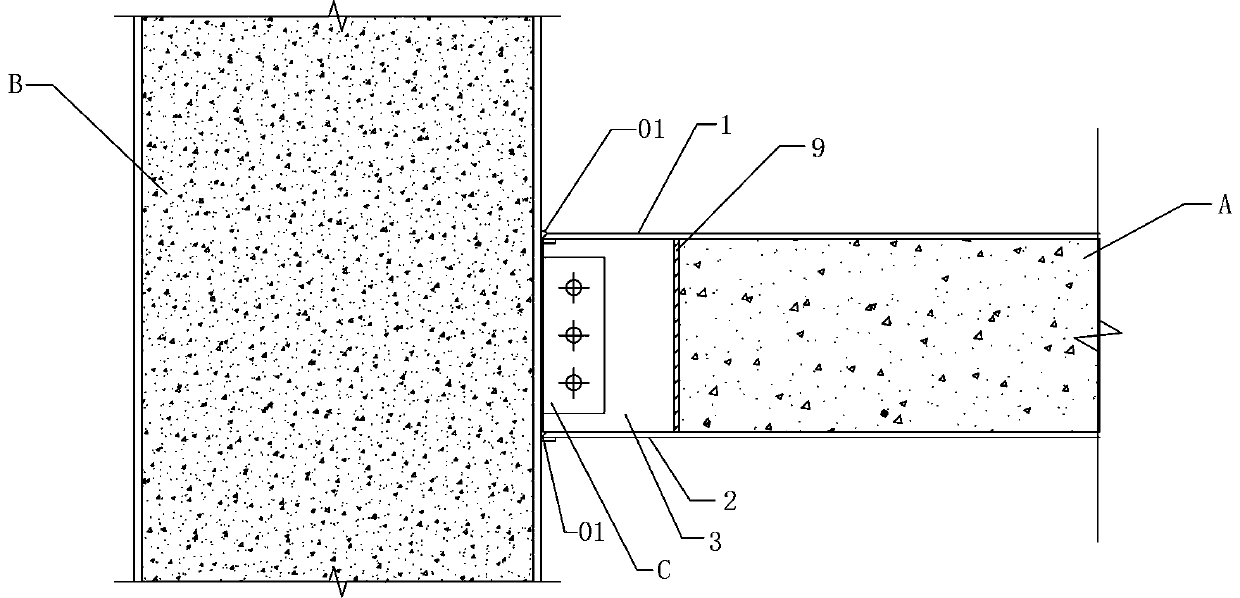

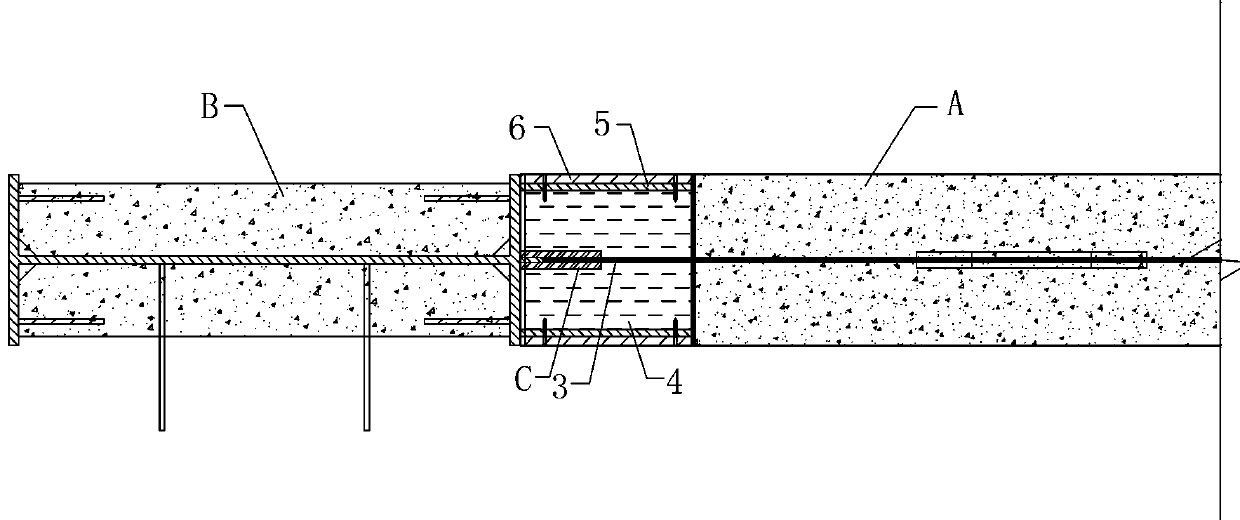

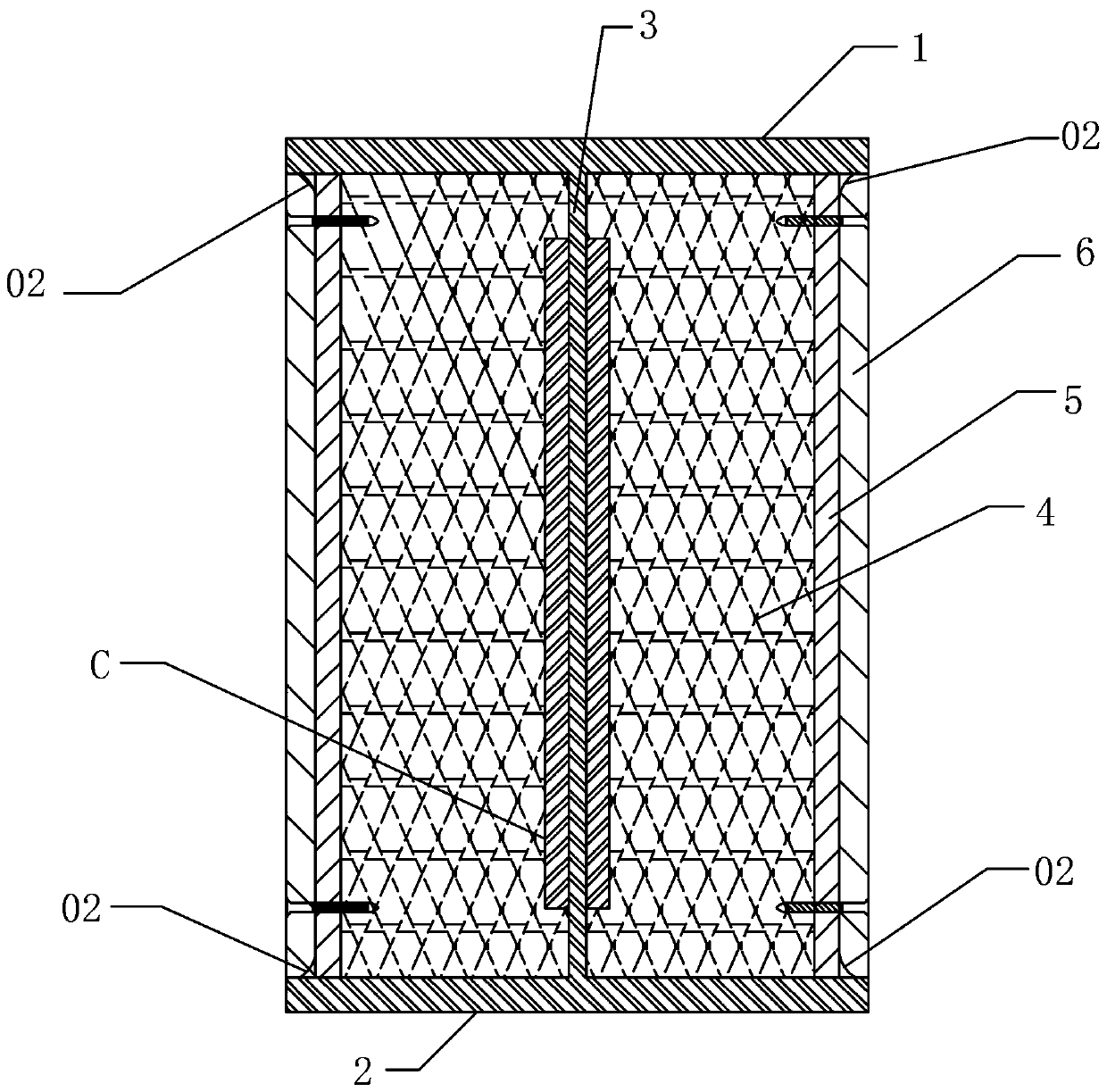

[0035] Below in conjunction with accompanying drawing, the present invention will be further described by specific embodiment:

[0036] This embodiment is different from the traditional wet construction, but is suitable for the dry construction scheme of the node structure of the fabricated PEC structure, whether it is beam-column butt joint or beam-beam butt joint, it can be implemented.

[0037] See figure 1 , figure 2 , image 3 , Figure 4 , taking beam-column butt joint as an example in the figure, the step ① is to reserve the "H" joint steel section, and set stiffening ribs near the end of a prefabricated beam steel member A to form "H" type node steel section and the main body of prefabricated beam steel member A; the existing prefabricated beam steel member A is usually "H" type steel member, prefabricated column steel member B can also be this kind of steel member, "H The "type node steel structure section is integrally formed at one end of the "H"-shaped steel m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com