Excavation method of tunnel shaft

A shaft and tunnel technology, applied in shaft equipment, drilling equipment and methods, well sinking and other directions, can solve the problems of long safety risk period, low construction efficiency, high safety risk, etc., to reduce safety risks, improve construction efficiency, The effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

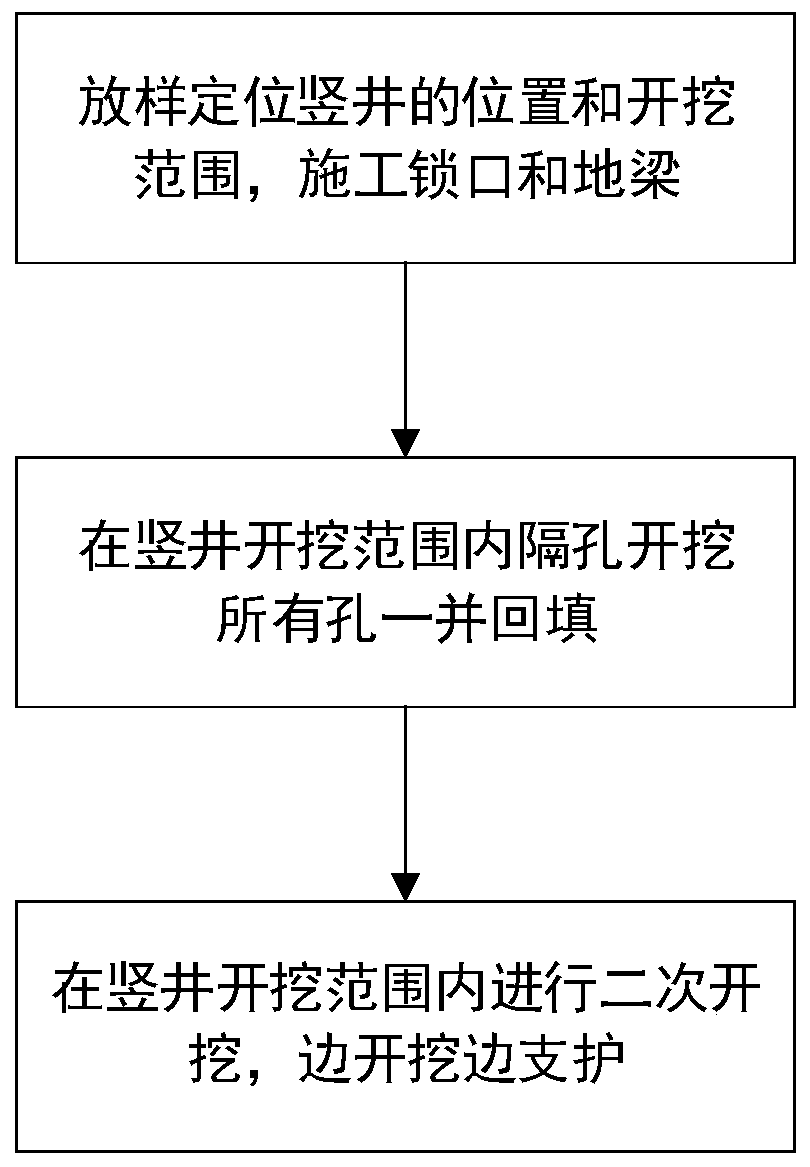

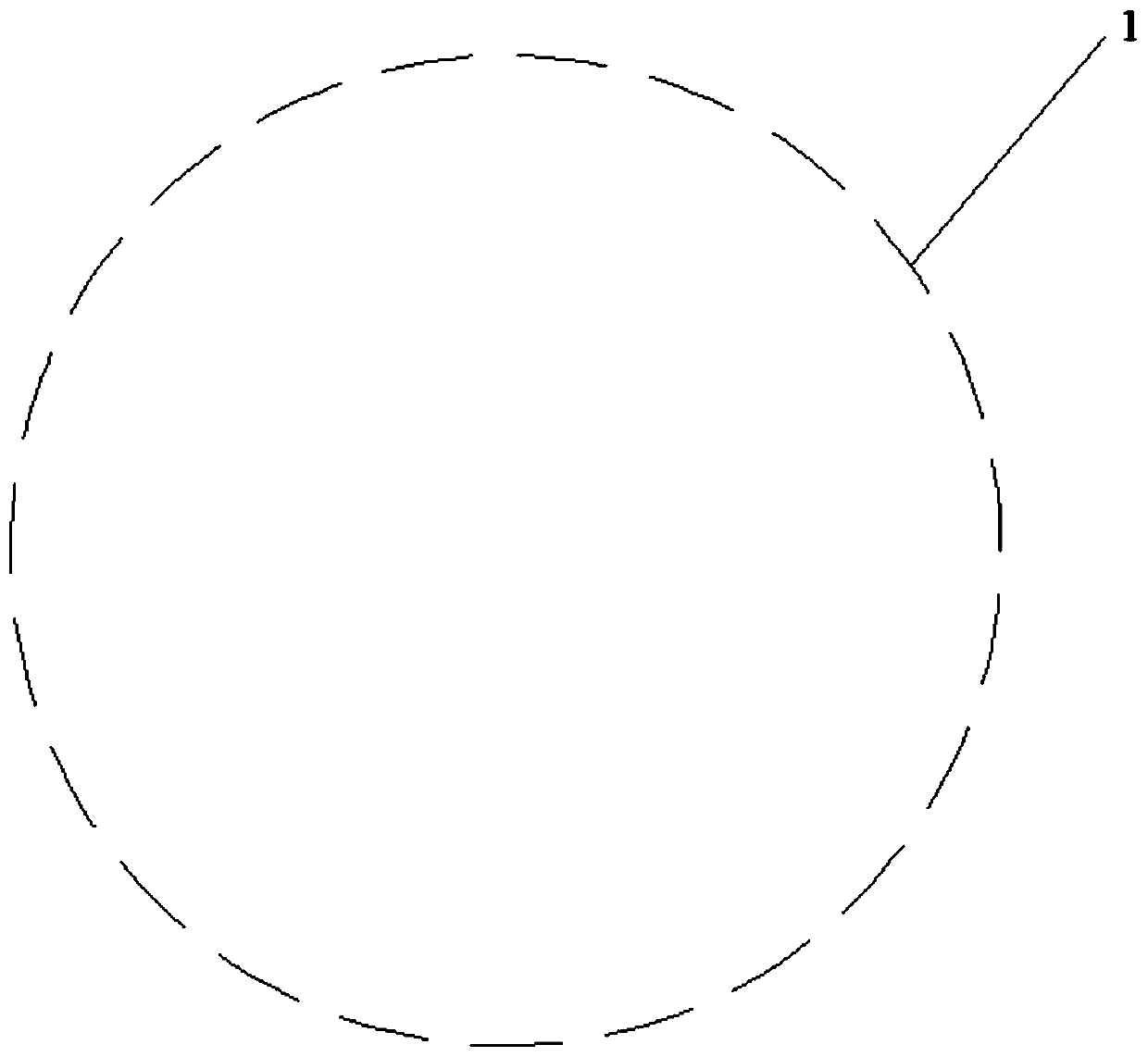

[0039] Such as figure 1 As shown, a method for excavating a tunnel shaft according to the present invention comprises the following steps:

[0040] a, stake out the central position of the vertical shaft 1, mark the excavation range of the vertical shaft 1 according to the positioning center point, and then construct the reinforced concrete lock and the ground beam at the wellhead of the vertical shaft 1;

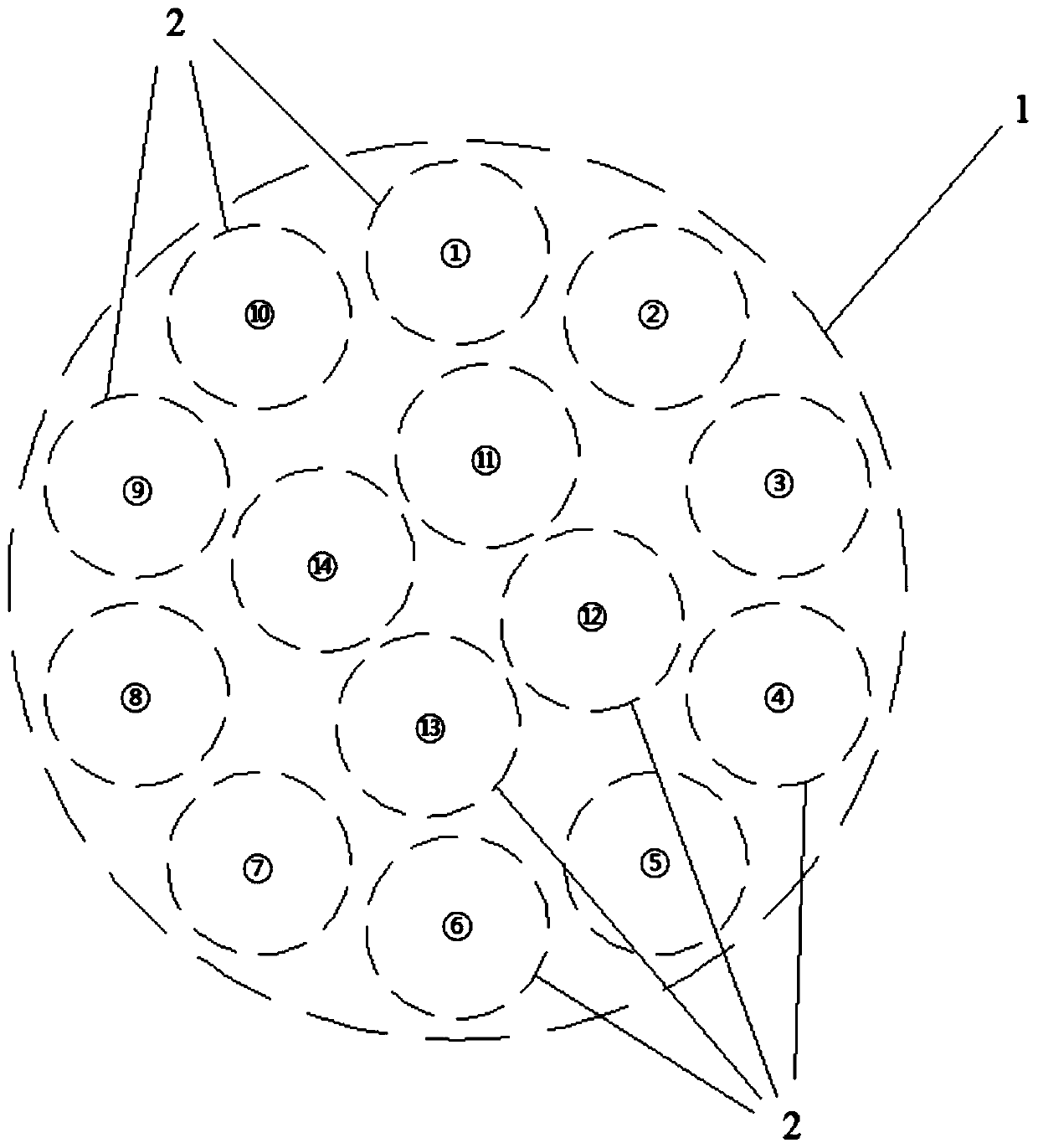

[0041] b. In the range to be excavated of the shaft 1, mark the range to be excavated of several holes-2, there is an interval between two adjacent holes-2, the interval is 10-20cm, and then use Excavate all the holes 1-2 sequentially in the order of the periphery first and then the center. When excavating all the holes 1-2, excavate every other hole. After each hole 2 is excavated to the bottom, mix the drilling slag with cement Backfilling back into the corresponding hole-2, and then excavating the next hole-2;

[0042] c. After the last hole-2 is backfilled, carry out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com