Thermal-insulation and heat-preservation material for special-type carriage or square cabin and structure

A technology for thermal insulation and compartments, which is applied in the direction of thermal insulation protection of pipelines, thermal insulation, pipeline protection, etc., can solve the problems of thick thermal insulation materials, affecting internal safety performance, affecting protection performance, etc., to achieve heat insulation, insulation Good thermal insulation effect and high installation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

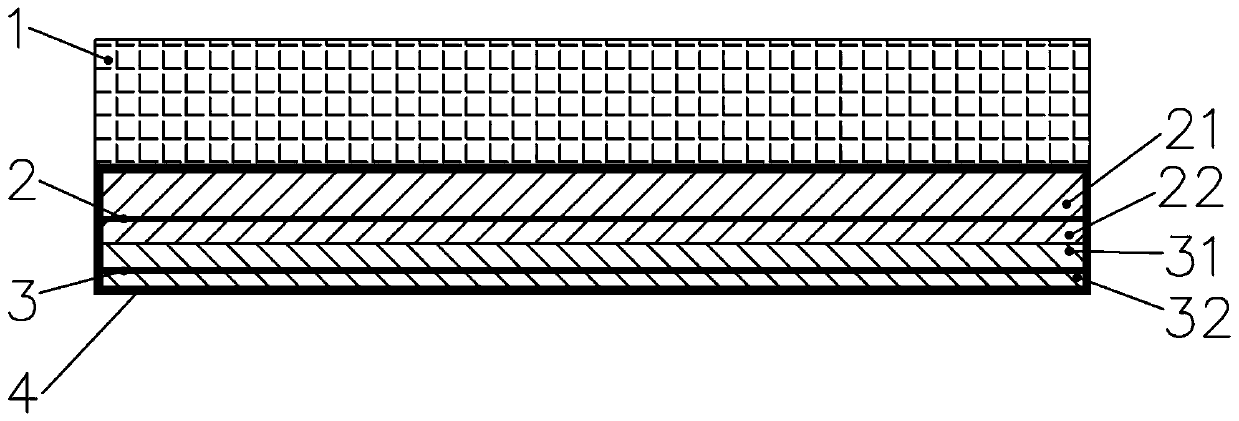

[0020] Such as figure 1 As shown, a thermal insulation material and structure for special carriages or shelters, coated on the inner wall surface of the carriage or shelter steel plate 1, is characterized in that it is heat-resistant sequentially from the inner surface of the carriage or shelter steel plate 1 inward Thermal insulation layer 2, low thermal conductivity thermal insulation layer 3; wherein the high temperature resistant thermal insulation layer 2 is a multi-layer laminated structure, from the surface of the cabin or shelter steel plate 1 inward, there are a high reflection layer a 21 and a high thermal resistance layer a 22 Alternate stacking (due to the need to ensure the clarity of the drawings, there are only two layers in the drawings, which are actually multi-layer stacks); the low thermal conductivity insulation layer 3 is a multi-layer stack structure, from the surface of the high temperature heat insulation layer 2 inward The high reflective layer b 31 and...

Embodiment 2

[0025] Such as figure 1 As shown, a thermal insulation material and structure for special carriages or shelters, coated on the inner wall surface of the carriage or shelter steel plate 1, is characterized in that it is heat-resistant sequentially from the inner surface of the carriage or shelter steel plate 1 inward Thermal insulation layer 2, low thermal conductivity thermal insulation layer 3; wherein the high temperature resistant thermal insulation layer 2 is a multi-layer laminated structure, from the surface of the cabin or shelter steel plate 1 inward, there are a high reflection layer a 21 and a high thermal resistance layer a 22 Alternate stacking (due to the need to ensure the clarity of the drawing, only two layers are stacked in the drawing, which is actually a multi-layer stack); the low thermal conductivity insulation layer 3 is a multi-layer stack structure, from the surface of the high temperature heat insulation layer 2 inward The high reflective layer b 31 and...

Embodiment 3

[0030] Such as figure 1 As shown, a thermal insulation material and structure for special carriages or shelters, coated on the inner wall surface of the carriage or shelter steel plate 1, is characterized in that it is heat-resistant sequentially from the inner surface of the carriage or shelter steel plate 1 inward Thermal insulation layer 2, low thermal conductivity thermal insulation layer 3; wherein the high temperature resistant thermal insulation layer 2 is a multi-layer laminated structure, from the surface of the cabin or shelter steel plate 1 inward, there are a high reflection layer a 21 and a high thermal resistance layer a 22 Alternate stacking (due to the need to ensure the clarity of the drawing, only two layers are stacked in the drawing, which is actually a multi-layer stack); the low thermal conductivity insulation layer 3 is a multi-layer stack structure, from the surface of the high temperature heat insulation layer 2 inward The high reflective layer b 31 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com