Armored thermometer for reactor coolant pump

A technology for coolant pumps and reactors, applied in the field of armored thermometers, which can solve problems such as oil leakage from the outer protective layer of PTFE, affecting the safe and stable operation of reactor coolant pumps, and broken wires of thermometer leads. The impact ability of mechanical equipment, which is conducive to coiling and fixing, and the effect of enhancing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

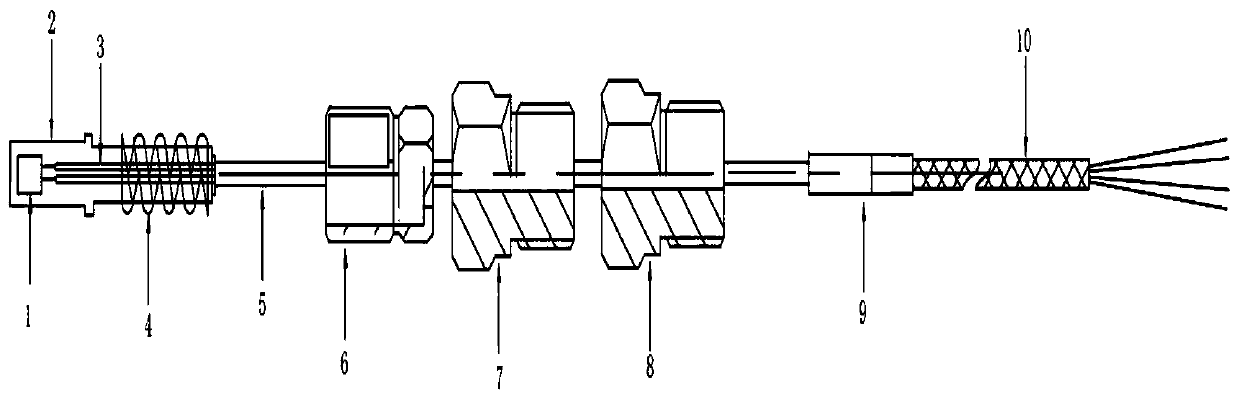

[0020] The armored thermometer for reactor coolant pumps provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] Such as figure 1 As shown, a kind of armored thermometer for reactor coolant pump provided by the present invention comprises a Pt100 thermal resistance 1, a metal protective sleeve 2, a four-core lead wire 3, a spring sleeve 4, an armored outer protective layer 5, an installation Bolt 6, through hole A bolt 7, through hole B bolt 8, cold end joint 9, polytetrafluoroethylene outer protective layer 10,

[0022] The Pt100 thermal resistance 1 and one end of the four-core lead wire 3 are connected together by welding, and the Pt100 thermal resistance 1 is packaged inside the metal protective sleeve 2,

[0023] The resistance value of the Pt100 thermal resistance 1 changes with temperature, and the metal protection sleeve 2 is made of stainless steel, and the inside of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com