Calculation method for automatically monitoring water surface evaporation capacity by active drainage method

A technology of automatic monitoring and water surface evaporation, which is applied in the direction of instruments, etc., can solve the problems that cannot meet the measurement accuracy requirements, cannot be popularized and applied, and the water is easy to decay and deteriorate, and achieves the reduction of manual intervention, high economic and social benefits, and simple methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

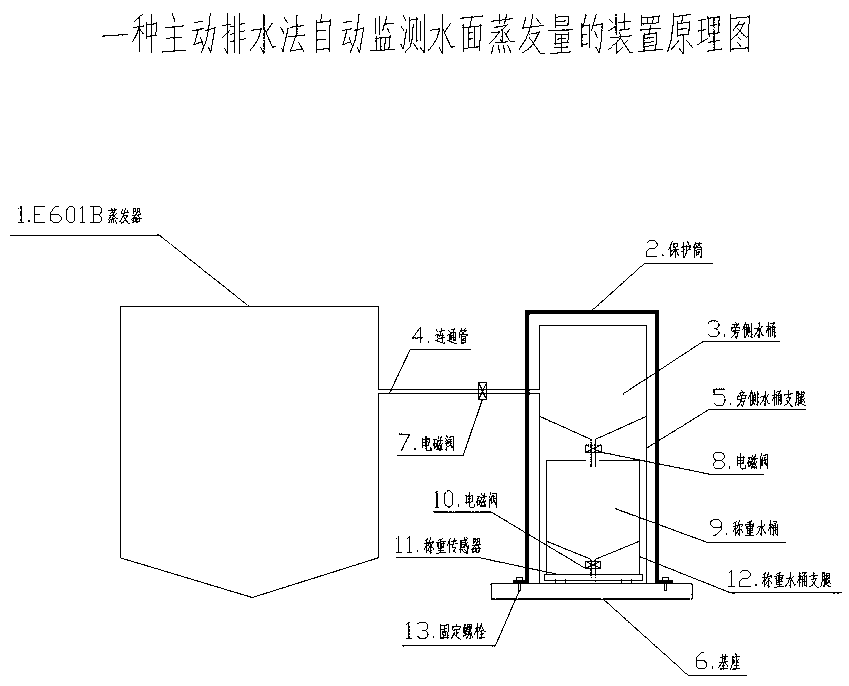

[0037] In the figure, 1-evaporator, 2-protective cylinder, 3-side bucket, 4-connecting pipe, 5-leg of side bucket, 6-base, 7-connecting pipe solenoid valve, 8-outlet pipe solenoid valve , 9-weighing bucket, 10-drain solenoid valve, 11-load sensor, 12-weighing bucket leg, 13-fixing bolt.

[0038] A protection cylinder 2 is installed beside the E601B evaporator 1, and a side bucket 3 with a diameter of 200 mm is installed inside the protection cylinder 2. The lower part of the side bucket 3 communicates with the evaporator 1 through a communication pipe 4. Legs 5 and supporting legs 5 are fixed on the base 6, and the protective tube 2 is installed on the base 6; a solenoid valve 7 is set on the connecting pipe 4, and the upper part of the side bucket 3 is cylindrical, and the lower part is a funnel, and the outlet pipe of the funnel is Electromagnetic valve 8 is installed; Weighing bucket 9 is set under the outlet pipe, and the outlet pipe goes deep into the inside of weighing b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com