System wind resistance characteristic simulation method

A technology of wind resistance characteristics and simulation methods, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve problems such as increasing fan selection, system thermal simulation workload, difficulty in finding suitable fans, and increasing time costs. Achieve the effect of shortening the product development cycle, improving the one-time pass rate, and reducing the R&D cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

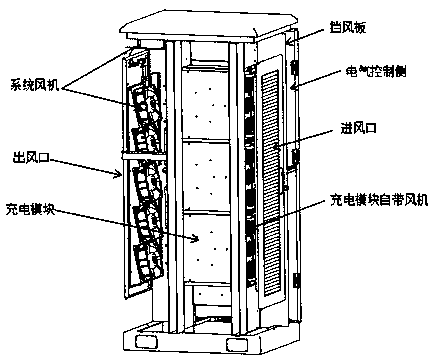

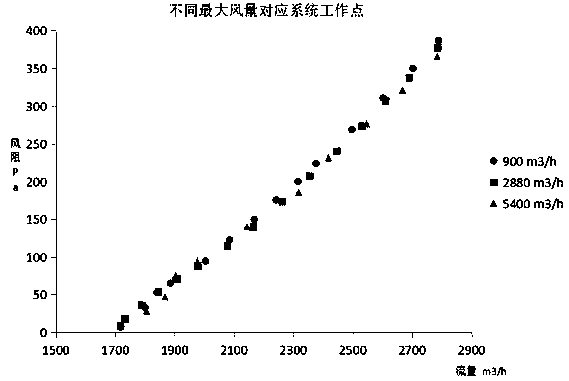

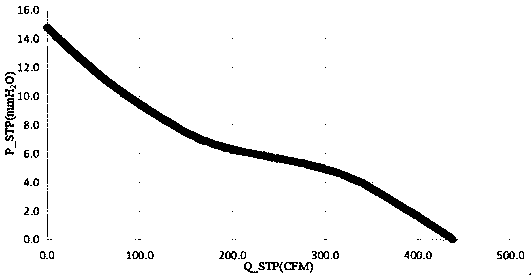

[0043] In the CFD simulation of the in-band fan electronic equipment system with a single system fan, when the air inlet and outlet are determined, the effective ventilation area of the fan is estimated; based on the 3D structural model of the electronic equipment, the relevant filter cotton, module wind resistance data and the PQ of the internal fan For parameters such as curves, modeling and parameter setting are carried out in the CFD simulation software. Among them, the system fan can be given with reference to the parameters of similar fan diameters or can be estimated; the above-mentioned model is meshed, and if the system is more complicated, it can be divided into blocks Use the method to refine the grid locally, adjust the grid according to the convergence situation, try the calculation until the residual curve converges, and continue to refine the grid until it has no effect on the simulation results; the maximum flow rate and maximum static pressure in the system fa...

Embodiment 2

[0045] In the CFD simulation of the in-band fan electronic equipment system with multi-system fan parallel connection, in the case of determining the air inlet and outlet, the effective ventilation area of the fan and the number of installed system fans are estimated; from the 3D structural model of the electronic equipment, related filter cotton, modules Parameters such as wind resistance data and PQ curve of the internal fan are modeled and parameterized in the CFD simulation software. The parameters of the system fan can be given with reference to the parameters of similar fan diameters or can be estimated; the above models are meshed , if the system is relatively complex, the grid can be locally refined by the block method, and the grid can be adjusted according to the convergence situation, and the trial operation can be performed until the residual curve converges, and the grid can be further refined until it has no effect on the simulation results; One of the maximum f...

Embodiment 3

[0047]In the CFD simulation of the in-band fan electronic equipment system with multi-system fans connected in series, when the air inlet and outlet are determined, the effective ventilation area of the fan and the number of fans installed in the system are estimated; the 3D structural model of the electronic equipment, the relevant filter cotton, and the wind resistance of the module Data and parameters such as the PQ curve of the internal fan are modeled and parameterized in the CFD simulation software. In addition, the outermost fan is regarded as the system fan, and the other fans are regarded as the internal fan. The internal fan required by the specified system that falls in the best working area, the selected system fan parameters can be given with reference to the parameters of similar fan diameters or can be estimated; the above model is meshed, and if the system is more complex, it can be divided into blocks Carry out local refinement of the grid, and adjust the gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com