A kind of high safety electrolyte and lithium ion battery

A lithium-ion battery, high-safety technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve the problems of reducing battery energy density, increasing battery volume, weight, etc., to improve battery safety, The effect of reducing reduction reactions and side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

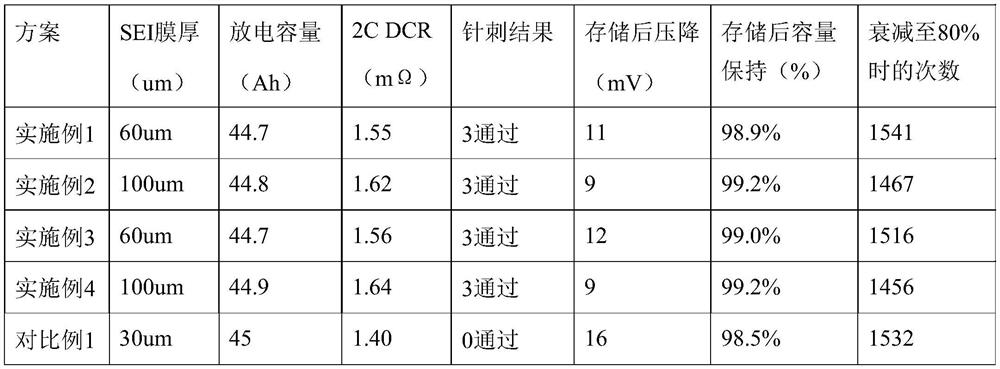

Embodiment 1

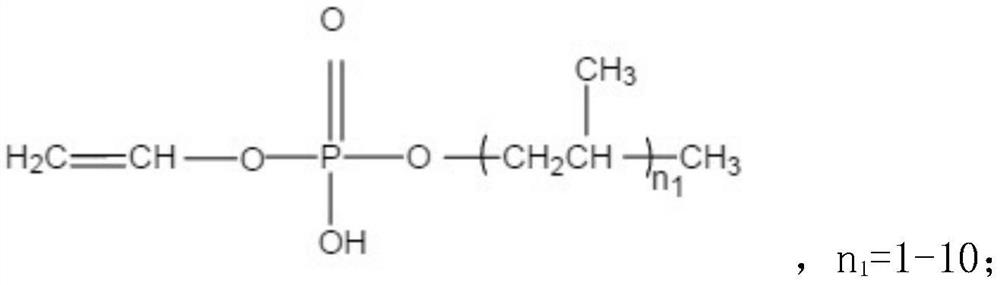

[0041] A high-safety electrolyte, which includes 3% reagent I (n=4), 3:7 EC and EMC, 1.15M LiPF 6 , 2% VC and 1% lithium difluorophosphate.

[0042] A high-safety lithium-ion battery includes a positive pole, a negative pole, a diaphragm and the electrolyte.

[0043] The pre-charging temperature of the electrolyte is 10-100°C; the thickness of the SEI film after pre-charging is more than or equal to 40nm.

[0044] The preparation method of the described high-safety lithium-ion battery comprises the steps of:

[0045] (1) Positive electrode: Dissolve 95.5% nickel-cobalt lithium manganese oxide, 2.5% conductive agent and 2% polyvinylidene fluoride in N-methyl-2-pyrrolidone to make positive electrode slurry. Coat the slurry on aluminum foil, dry, roll, and die cut into 232*189mm;

[0046] (2) Negative electrode: Dissolve 95.5% graphite, 1% conductive agent, 1.5% CMC and 2% SBR in deionized water to make negative electrode slurry, coat the slurry on aluminum foil, dry, roll, mo...

Embodiment 2

[0051] A high-safety electrolyte, which includes 4% reagent I (n=10), 3:7 EC and EMC, 1.15M LiPF 6 , 2% VC and 1% lithium difluorophosphate.

[0052] A high-safety lithium-ion battery includes a positive pole, a negative pole, a diaphragm and the electrolyte.

[0053] The pre-charging temperature of the electrolyte is 10-100°C; the thickness of the SEI film after pre-charging is more than or equal to 40nm.

[0054] The preparation method of the described high-safety lithium-ion battery comprises the steps of:

[0055] (1) Positive electrode: Dissolve 95.5% nickel-cobalt lithium manganese oxide, 2.5% conductive agent and 2% polyvinylidene fluoride in N-methyl-2-pyrrolidone to make positive electrode slurry. Coat the slurry on aluminum foil, dry, roll, and die cut into 232*189mm;

[0056] (2) Negative electrode: Dissolve 95.5% graphite, 1% conductive agent, 1.5% CMC and 2% SBR in deionized water to make negative electrode slurry, coat the slurry on aluminum foil, dry, roll, m...

Embodiment 3

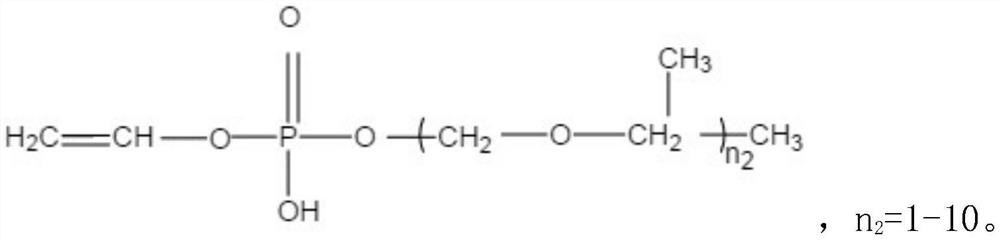

[0061] A high-safety electrolyte, which includes 3% reagent II (n=3), 3:7 EC and EMC, 1.15M LiPF 6 , 2% VC and 1% lithium difluorophosphate.

[0062] A high-safety lithium-ion battery includes a positive pole, a negative pole, a diaphragm and the electrolyte.

[0063] The pre-charging temperature of the electrolyte is 10-100°C; the thickness of the SEI film after pre-charging is more than or equal to 40nm.

[0064] The preparation method of the described high-safety lithium-ion battery comprises the steps of:

[0065] (1) Positive electrode: Dissolve 95.5% nickel-cobalt lithium manganese oxide, 2.5% conductive agent and 2% polyvinylidene fluoride in N-methyl-2-pyrrolidone to make positive electrode slurry. Coat the slurry on aluminum foil, dry, roll, and die cut into 232*189mm;

[0066] (2) Negative electrode: Dissolve 95.5% graphite, 1% conductive agent, 1.5% CMC and 2% SBR in deionized water to make negative electrode slurry, coat the slurry on aluminum foil, dry, roll, m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com