Linear actuator

A technology of linear actuators and actuating elements, which is applied in the direction of transmission, electric components, and control/drive circuits, etc., which can solve the problems of high assembly cost and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

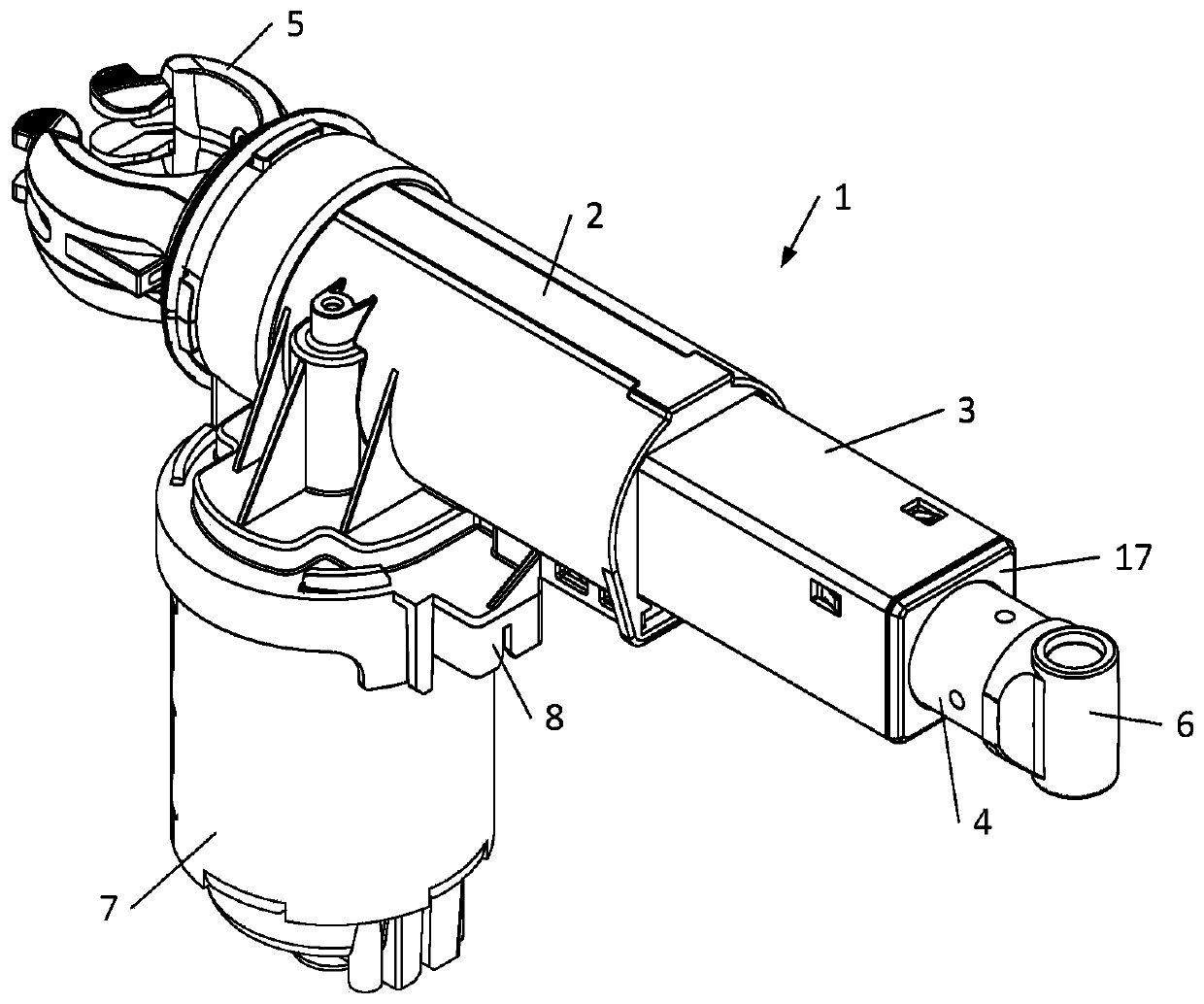

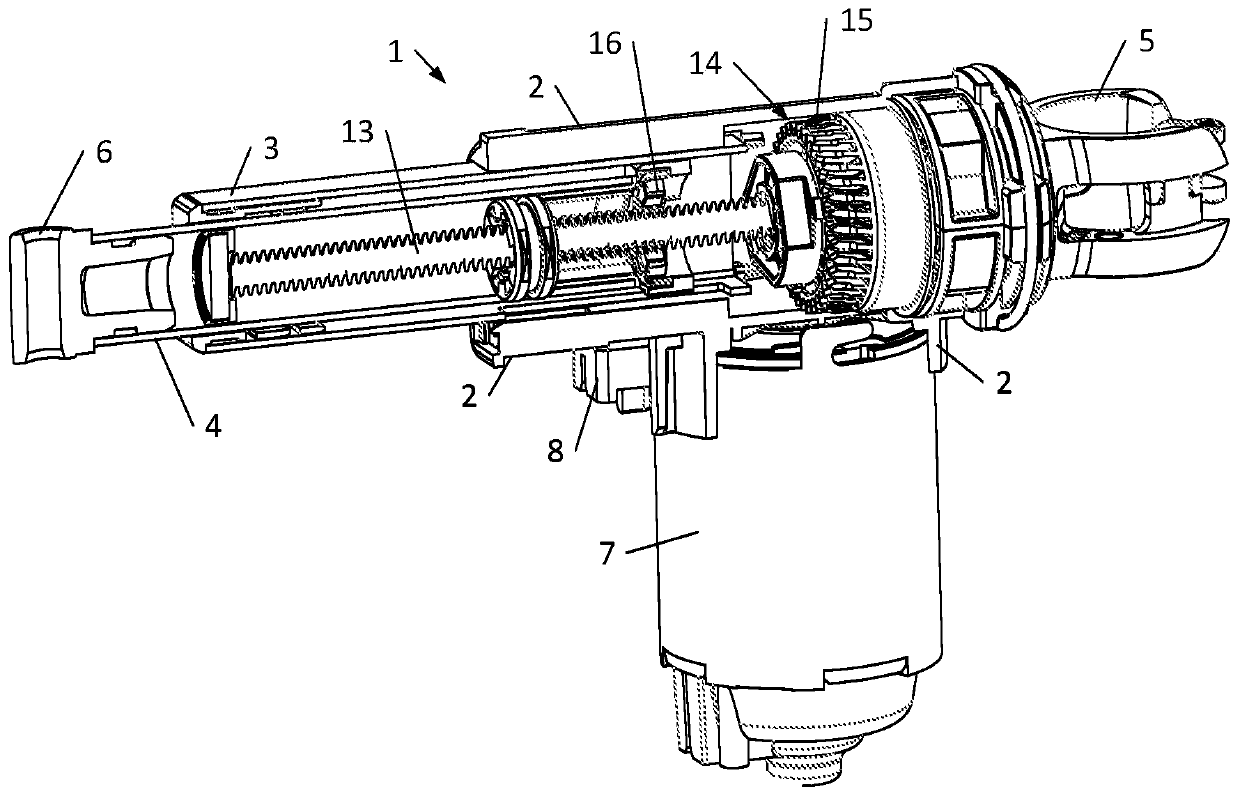

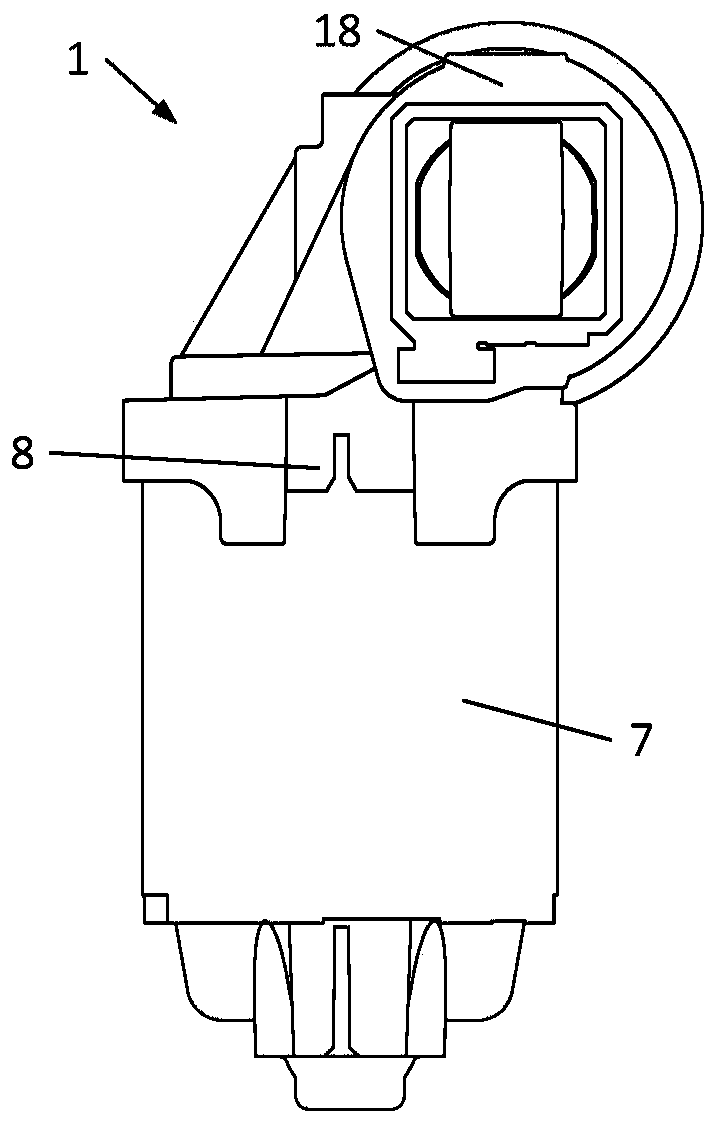

[0034] figure 1 A perspective view of a linear actuator 1 is shown comprising a console 2 , an outer tube 3 and an inner tube 4 guided in the outer tube 3 . For mounting the linear actuator, the rear end is equipped with a rear mount 5 and the front end of the inner tube 4 is equipped with a front mount 6 . Such as figure 1 and figure 2 As shown, the linear actuator 1 comprises a motor 7, typically a reversible motor, which may be a DC or AC motor for low or mains voltage. A motor 7 is mounted to the bottom of the console 2 , and a rear mount 5 is mounted to the rear end of the console 2 .

[0035] The linear actuator 1 comprises a socket 8 for connecting the linear actuator 1 to a power source or an electric controller.

[0036] The outer tube 3 comprises a rectangular section, in particular a square section, ie the outer tube 3 comprises four walls.

[0037] The linear actuator 1 also includes a main shaft 13, the main shaft 13 is driven by the motor 7 through a transm...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap