Ultrasonic-assisted enhanced turbulence cyclone reactor for preparing fine particles

An ultrasonic-assisted, fine-particle technology, applied in chemical instruments and methods, chemical/physical/physical-chemical processes applying energy, and chemical liquid coagulation, etc. The effect of low equipment cost, simple structure and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below through specific embodiments.

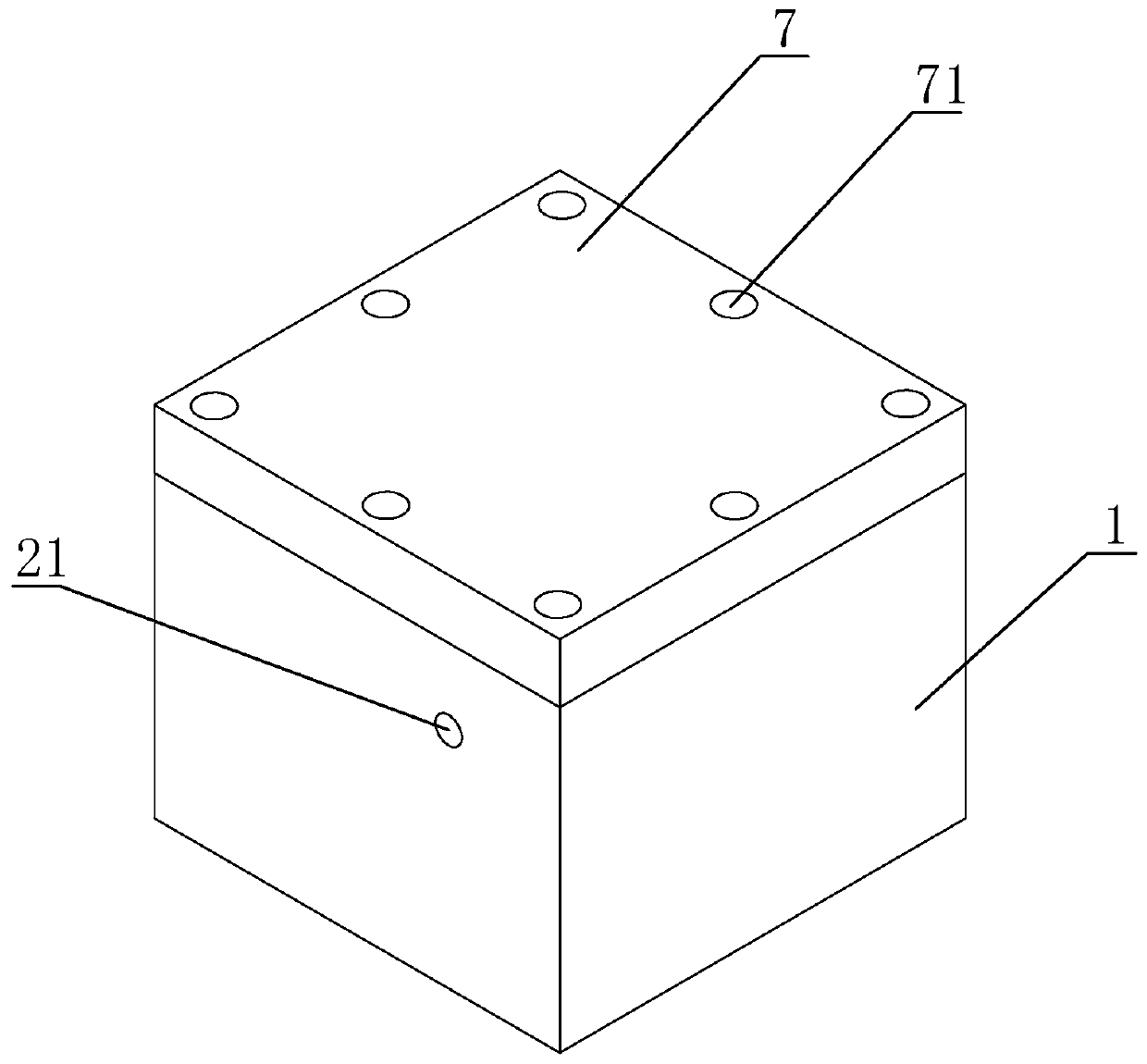

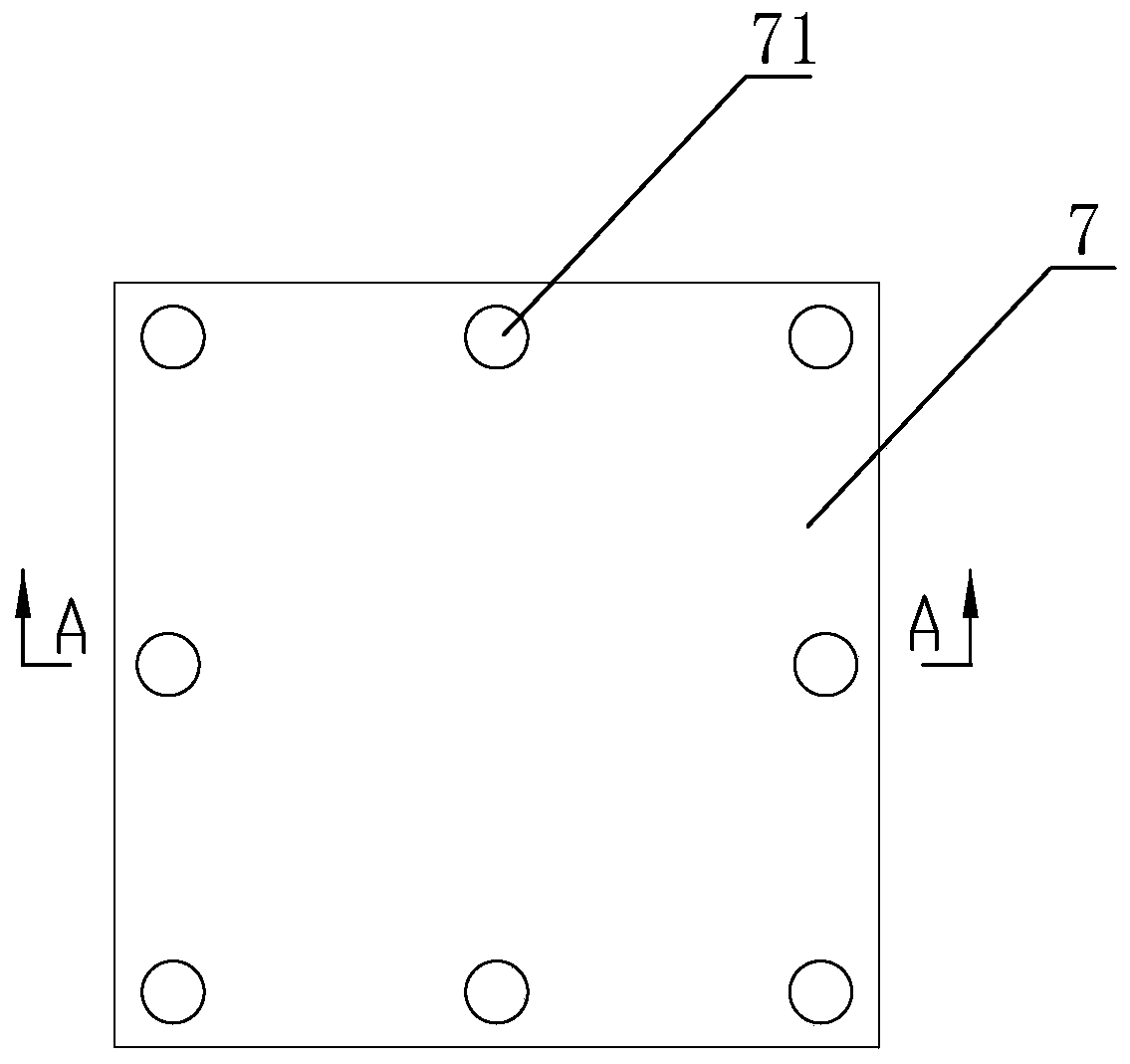

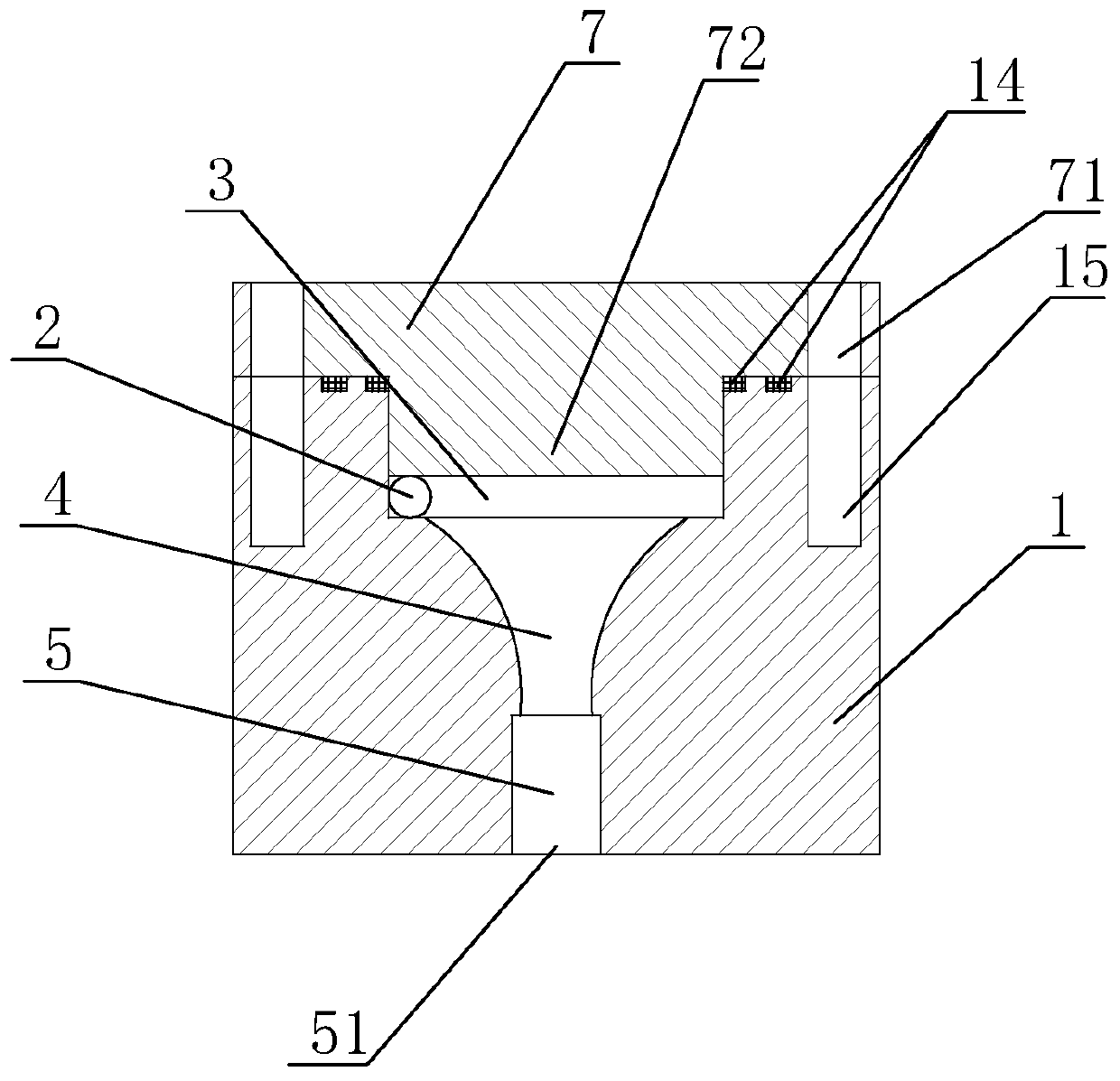

[0028] As shown in the figure, the ultrasonic-assisted enhanced turbulent cyclone reactor for preparing fine particles of the present invention includes a main body 1, and the main body 1 is sequentially arranged with: a feed channel 2 for providing a high-speed jet for the reaction, and a high-speed jet The jet forms a vortex flow and the reaction chamber 3 as a particle reaction site, the constriction chamber 4 that makes the particles coalesce and break up, and the discharge channel 5 for outputting fine particles; the flow direction of the reactant solution in the reactor is as follows: The feed channel 2, the reaction cavity 3, the shrinkage section cavity 4 and the discharge channel 5.

[0029] The cross-sections of the reaction chamber 3 and the shrinkage section chamber 4 are circular, and the central axes of the reaction chamber 3 and the shrinkage section chamber 4 coincide, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com