Slag washing device for lithium battery recycling

A lithium battery and slag washing technology, which is applied in the direction of dry gas arrangement, cleaning method and utensils, cleaning method using liquid, etc., can solve problems such as unsupported table cleaning, achieve the effect of realizing recycling and improving adequacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

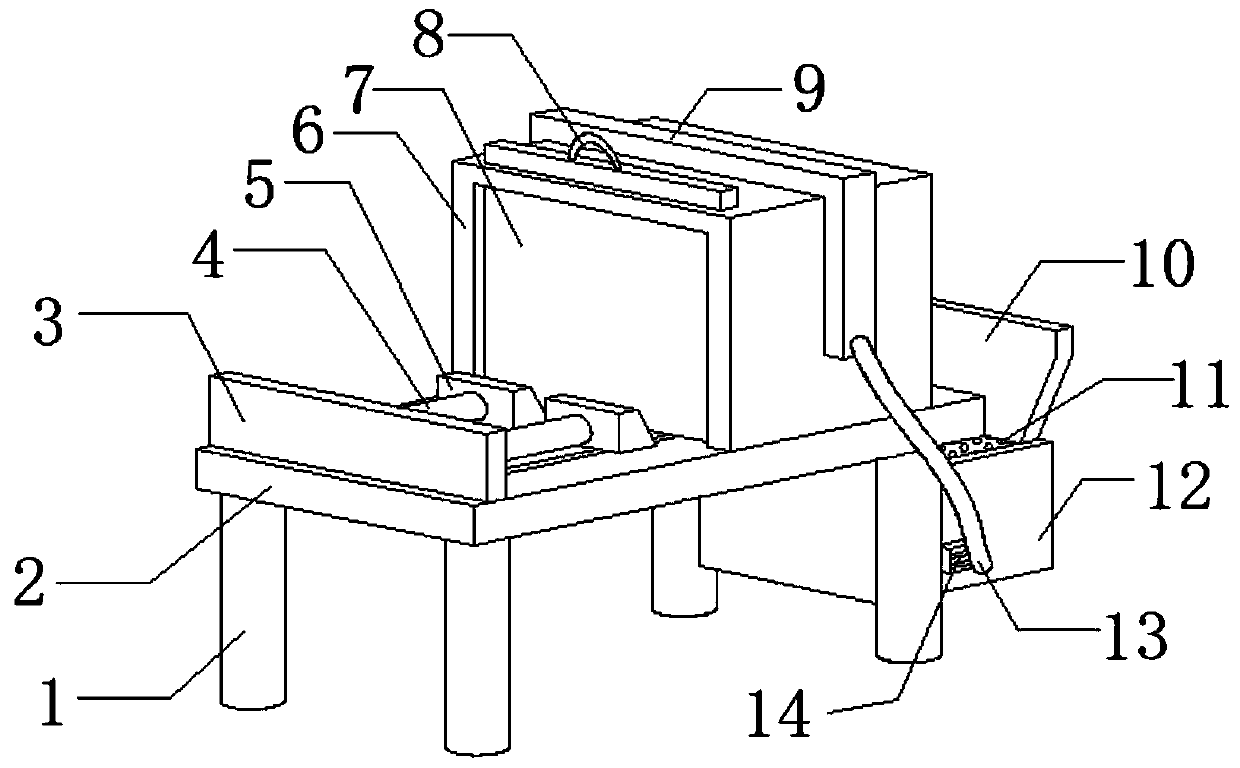

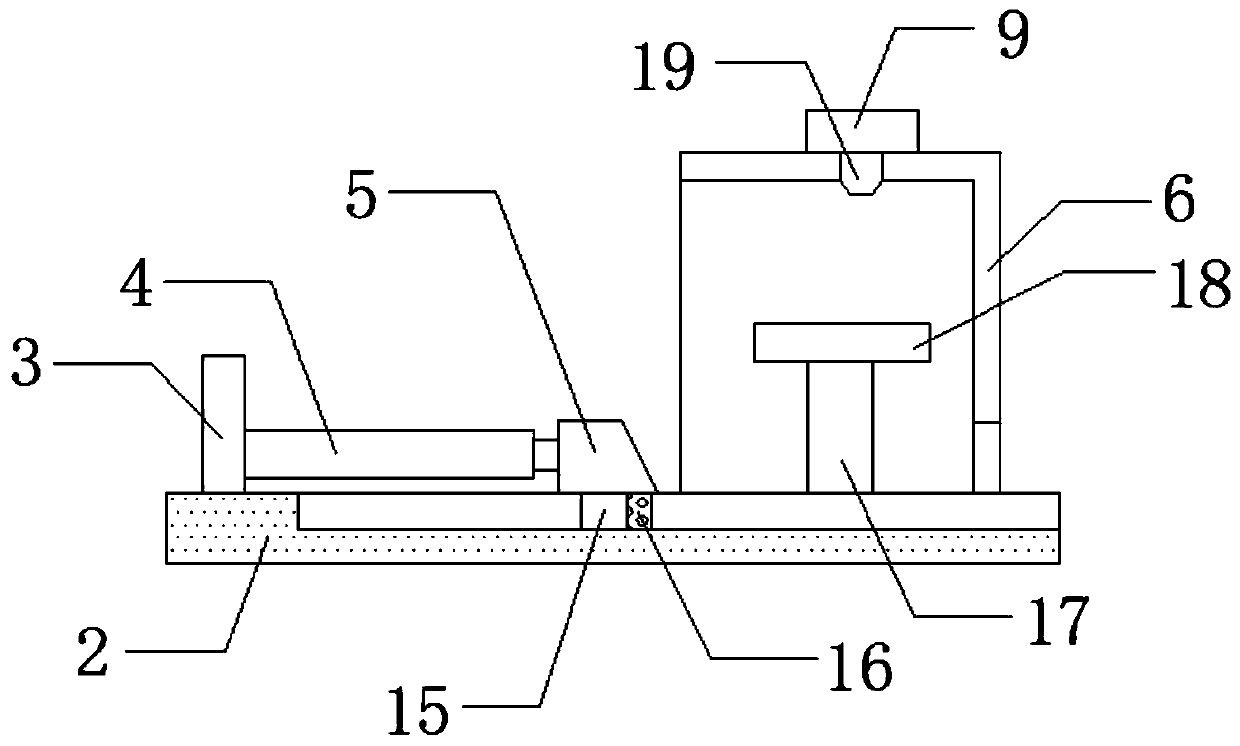

[0028] A kind of slag washing device for lithium battery recovery, such as Figure 1-2 As shown, it includes a support platform 2 and four support legs 1, and the four support legs 1 are respectively installed on the bottom four-corner outer walls of the support platform 2 by bolts. Sliders 15 are slidably arranged on the inner walls of the water tank, cloth pads 16 are connected to one side of the outer walls of the two sliders 15 by bolts, and push plates 5 are connected to the top outer walls of the two sliders 15 by bolts, and the top of the support platform 2 The outer wall on one side is connected with a baffle plate 3 by bolts, and the outer walls at both ends of one side of the baffle plate 3 are connected with electric telescopic rods 4 arranged horizontally by bolts, and the outer walls on one side of the two electric telescopic rods 4 are respectively connected with two electric telescopic rods by bolts. One side outer wall of each push plate 5 is connected.

[002...

Embodiment 2

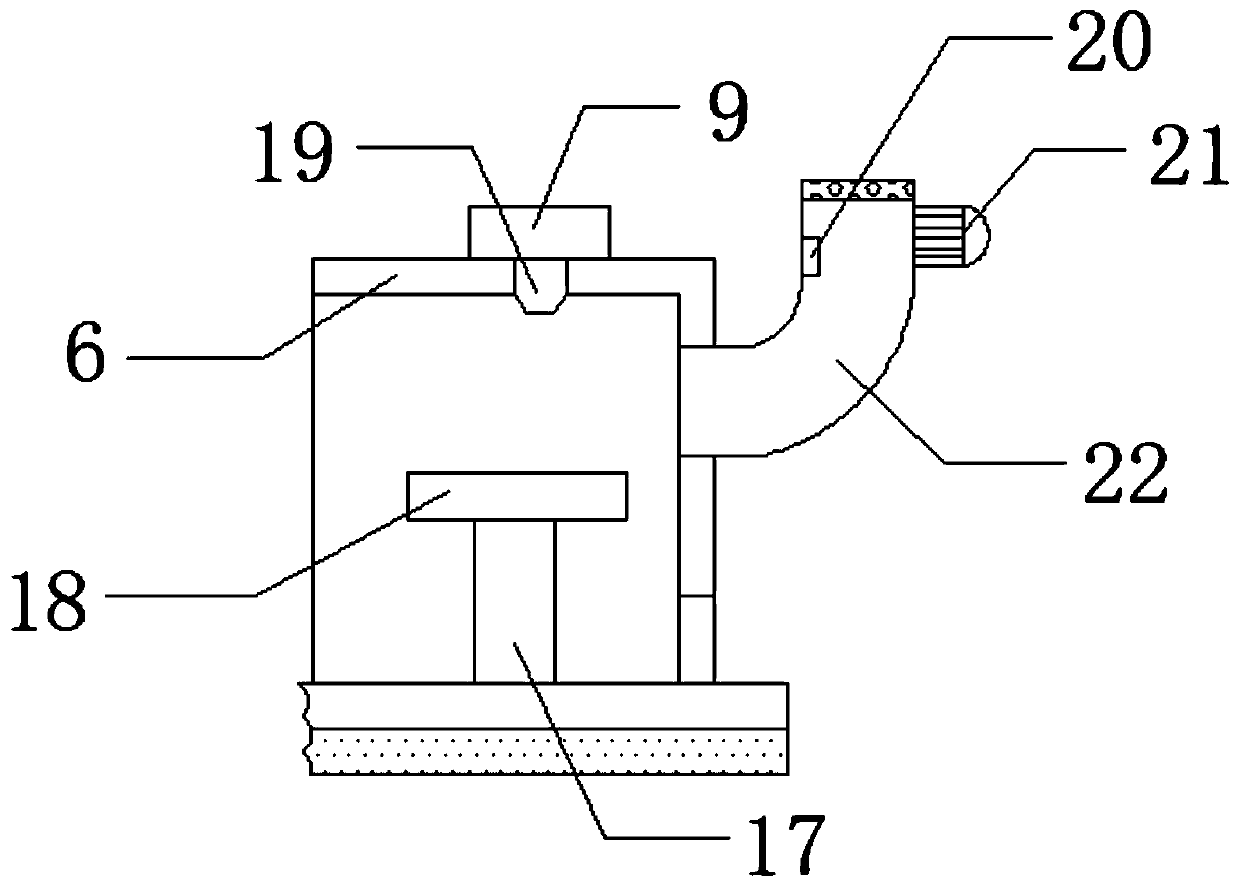

[0033] A kind of slag washing device for lithium battery recovery, such as Figure 1-3 As shown, it also includes an air guide pipe 22 installed on the top outer wall of the other side of the support housing 6 by bolts, and the inner wall on one side of the air guide pipe 22 is connected with a heater 20 by bolts, and the top of the other side of the air guide pipe 22 The outer wall is connected with a blower 21 through bolts, and the inner wall at the top of the circumference of the air guide pipe 22 is connected with a protective screen through bolts.

[0034] In this embodiment, after the slag washing of the lithium battery is completed, the blower 21 can be used to blow air to the lithium battery on the support plate 18, and the heater 20 can heat the air flow to ensure that the temperature is about 20 degrees, which can realize Effective air-drying treatment for lithium batteries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com