Embedded pulse generator for propeller automatic balance

An automatic balance and driver technology, applied in the direction of propeller, weight reduction, transportation and packaging, etc., can solve the problems of poor output pulse stability and accuracy, reduced volume and weight, difficult installation and debugging, etc., to achieve long service life, Effects of reducing size and weight and preventing equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] An embodiment of the present invention is as follows:

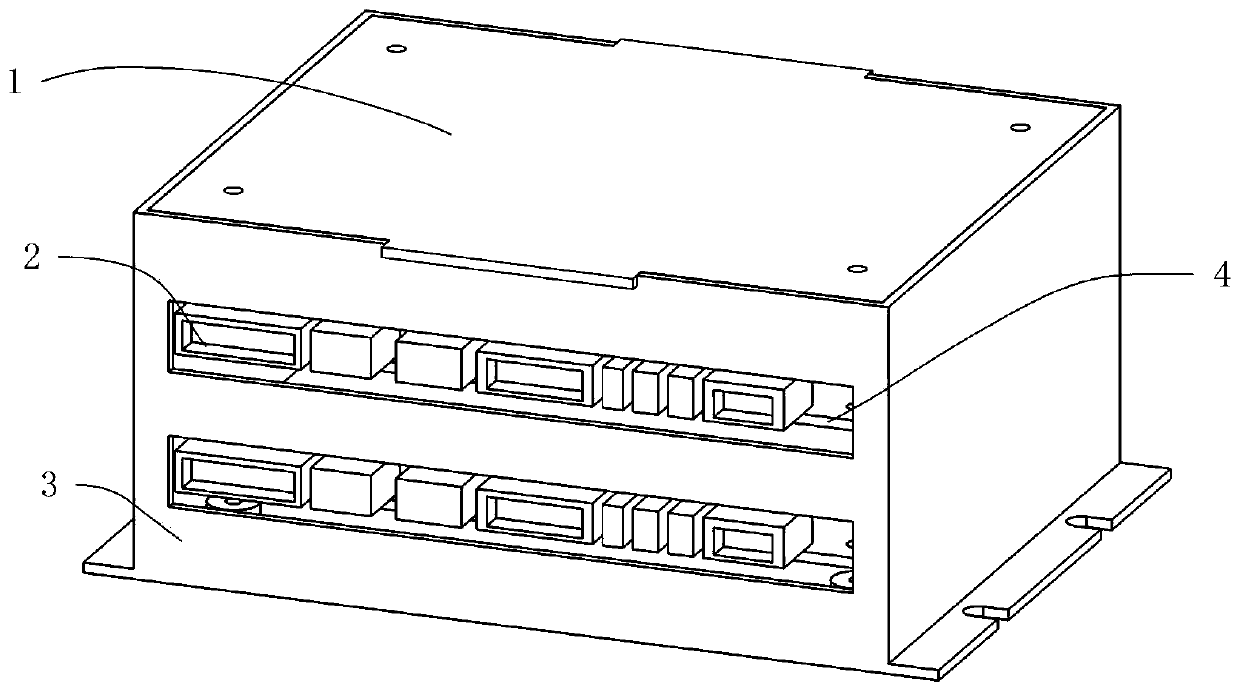

[0046] as attached figure 1 shown. The driving device of the electromagnetic automatic balancing actuator of the present application can only be equipped with one driving control board 4 and the supporting interface unit 2, and can be used with an electromagnetic automatic balancing actuator with a single counterweight plate.

[0047] The installation sequence of the drive unit is as follows:

[0048] First place the drive control board 4 on the support column inside the housing 3, align the interface unit 2 with the rectangular hole on the front side of the housing 3, and then tighten it with a copper column of the same length. Put the upper cover 1 into the groove on the upper part of the housing 3, and use bolts to fix the upper cover and the copper pillar together. Finally, use bolts to fix the driving device on the casing as a whole, and then connect all the cables firmly, so far the installation of the dri...

Embodiment 2

[0050] Another embodiment of the present invention is as follows:

[0051] as attached figure 1 shown. The driving device of the electromagnetic automatic balancing actuator of the present application can be installed with two driving control boards 4 and the supporting interface unit 2, and can be used with the electromagnetic automatic balancing actuator with double counterweight plates. The installation sequence of the drive unit is as follows:

[0052] First place the drive control board 4 on the support column inside the housing 3, align the interface unit 2 with the rectangular hole on the front side of the housing 3, and then use the same length of copper column to tighten it; then install the next drive control board 4. Place it on the copper column, align the interface unit 2 with the rectangular hole on the front side of the housing 3 and fix the control board with a short copper column, and finally put the upper cover 1 into the groove on the upper part of the hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com