Machine vision detection system and method

A machine vision detection and detection technology, which is applied in the direction of instruments, manipulators, measuring devices, etc., can solve the problems of time-consuming, time-consuming and labor-intensive installation and debugging of industrial hosts, and short transmission distances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

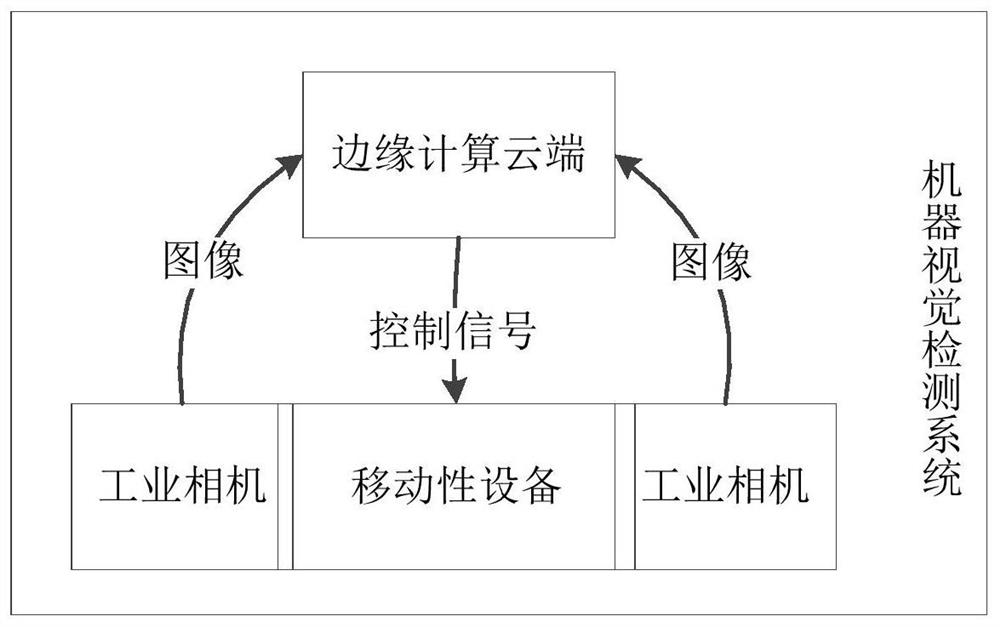

[0025] figure 1 It is a schematic structural diagram of a machine vision inspection system provided in Embodiment 1 of the present invention. This embodiment is applicable to the situation where a product is inspected by a machine vision inspection system.

[0026] Such as figure 1 As shown, the system includes: at least two industrial cameras, edge computing cloud, and mobile devices;

[0027] Wherein, at least two industrial cameras are arranged on the mobile device; the mobile device is used to drive the industrial cameras to move, so that each industrial camera can obtain images from different angles of the object to be detected.

[0028] In a specific implementation of the embodiment of the present invention, the industrial camera can be set on the mobile device through a mechanical connection. Driven by the mobile device, the industrial camera can take images from different angles of the object to be detected, and the object to be detected can be detected. Comprehensiv...

Embodiment 2

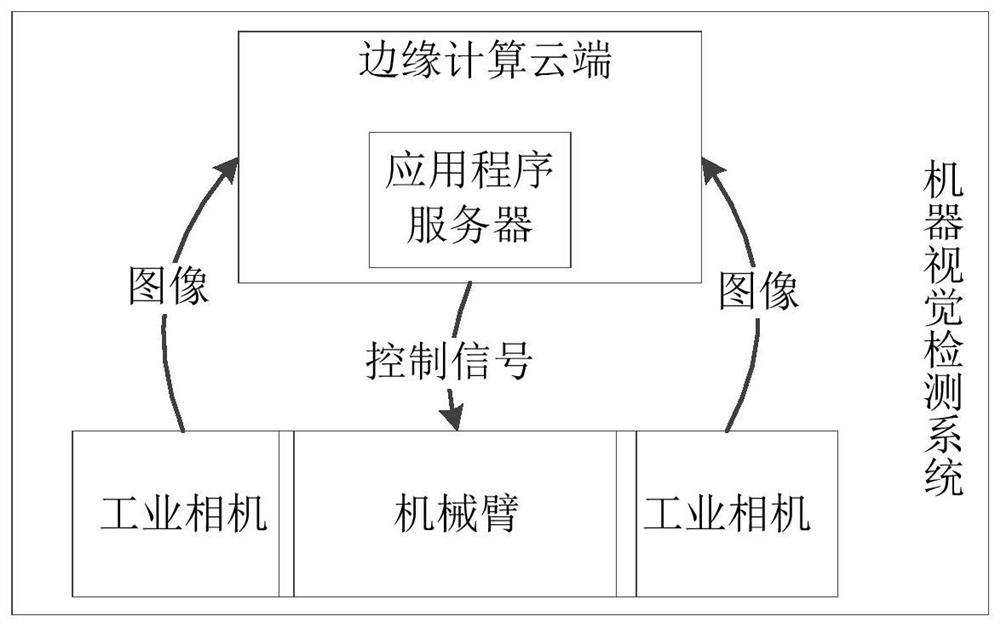

[0039] figure 2 It is a schematic structural diagram of a machine vision inspection system provided in Embodiment 2 of the present invention. This embodiment is a further refinement of the above-mentioned technical solution. The technical solution in this embodiment can be compared with each of the above-mentioned one or more embodiments. Optional combination.

[0040] Such as figure 2 As shown, the system includes: at least two industrial cameras, an edge computing cloud, and a mobile device; wherein at least two industrial cameras are set on the mobile device; the mobile device is used to drive the industrial camera to move so that Each industrial camera obtains images from different angles of the object to be detected; the edge computing cloud is used to receive the images uploaded by the industrial cameras, and process the images to obtain the detection results of the images.

[0041] Optionally, the industrial camera is also used to obtain the identification information...

Embodiment 3

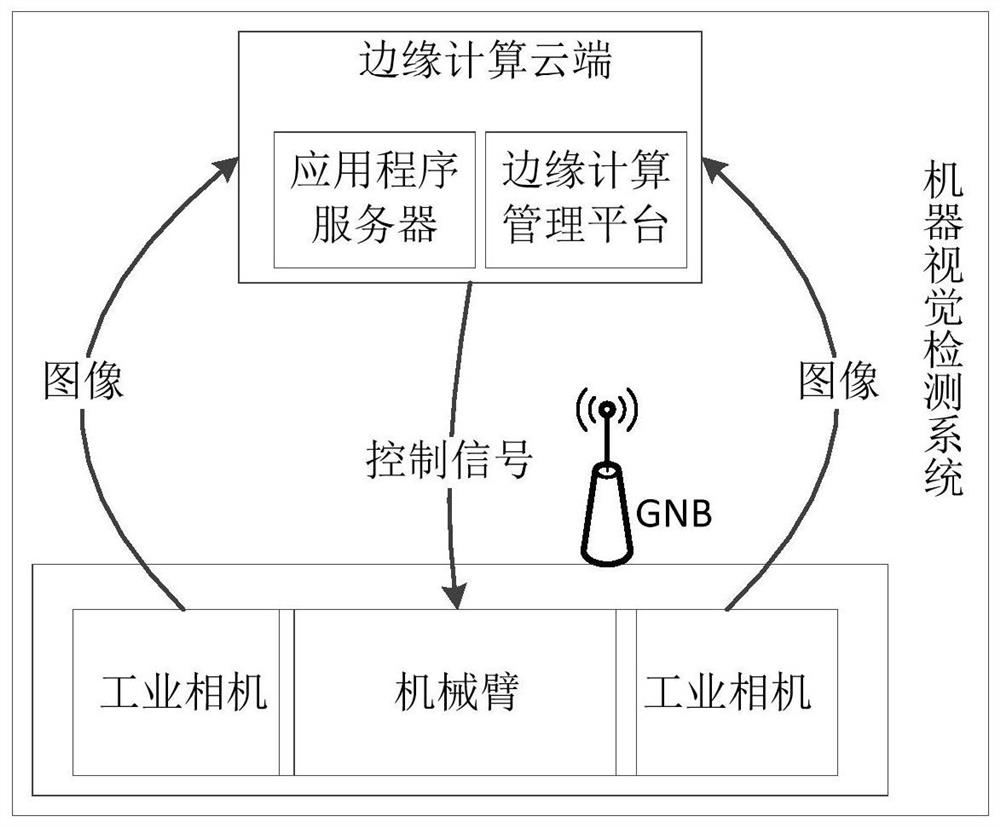

[0048] image 3 It is a schematic structural diagram of a machine vision inspection system provided by Embodiment 3 of the present invention. This embodiment is a further refinement of the above-mentioned technical solution. The technical solution in this embodiment can be compared with each of the above-mentioned one or more embodiments. Optional combination.

[0049] Such as image 3 As shown, the system includes: at least two industrial cameras, an edge computing cloud, and a mobile device; wherein at least two industrial cameras are set on the mobile device; the mobile device is used to drive the industrial camera to move so that Each industrial camera obtains images from different angles of the object to be detected; the edge computing cloud is used to receive the images uploaded by the industrial cameras, and process the images to obtain the detection results of the images.

[0050] Optionally, the industrial camera is also used to obtain the identification information...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com