MXene two-dimensional material and Cu/MXene catalyst, and preparation methods and applications thereof

A technology of two-dimensional materials and catalysts, applied in the direction of physical/chemical process catalysts, catalysts, catalyst carriers, etc., can solve the problems of complex post-processing methods, achieve good catalytic activity, avoid waste of resources, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A kind of preparation method of MXene two-dimensional material provided by one aspect of the embodiment of the present invention, it comprises:

[0034] The uniform mixed reaction system comprising lithium fluoride, acid and Mxene precursor is reacted at 20-60°C for 5-72h,

[0035] The obtained reaction product is mixed with water, and the obtained mixture is shaken for 10 to 1200 minutes, preferably 30 to 60 minutes, and then ultrasonically treated for 10 to 300 minutes to obtain the MXene two-dimensional material.

[0036] In some embodiments, the mass ratio of lithium fluoride to acid is 1:6˜1:40.

[0037] In some embodiments, the mass ratio of the Mxene precursor to lithium fluoride is 1:0.6˜1:2.4.

[0038] Further, the power of the ultrasonic treatment is 80W-360W.

[0039] Further, the Mxene precursor includes Ti 3 AlC 2 、Ti 2 AlC, V 2 AlC, Mo 2 AlC, Nb 2 Any one or a combination of two or more of AlC, etc., but not limited thereto.

[0040] Further, the ...

Embodiment 1

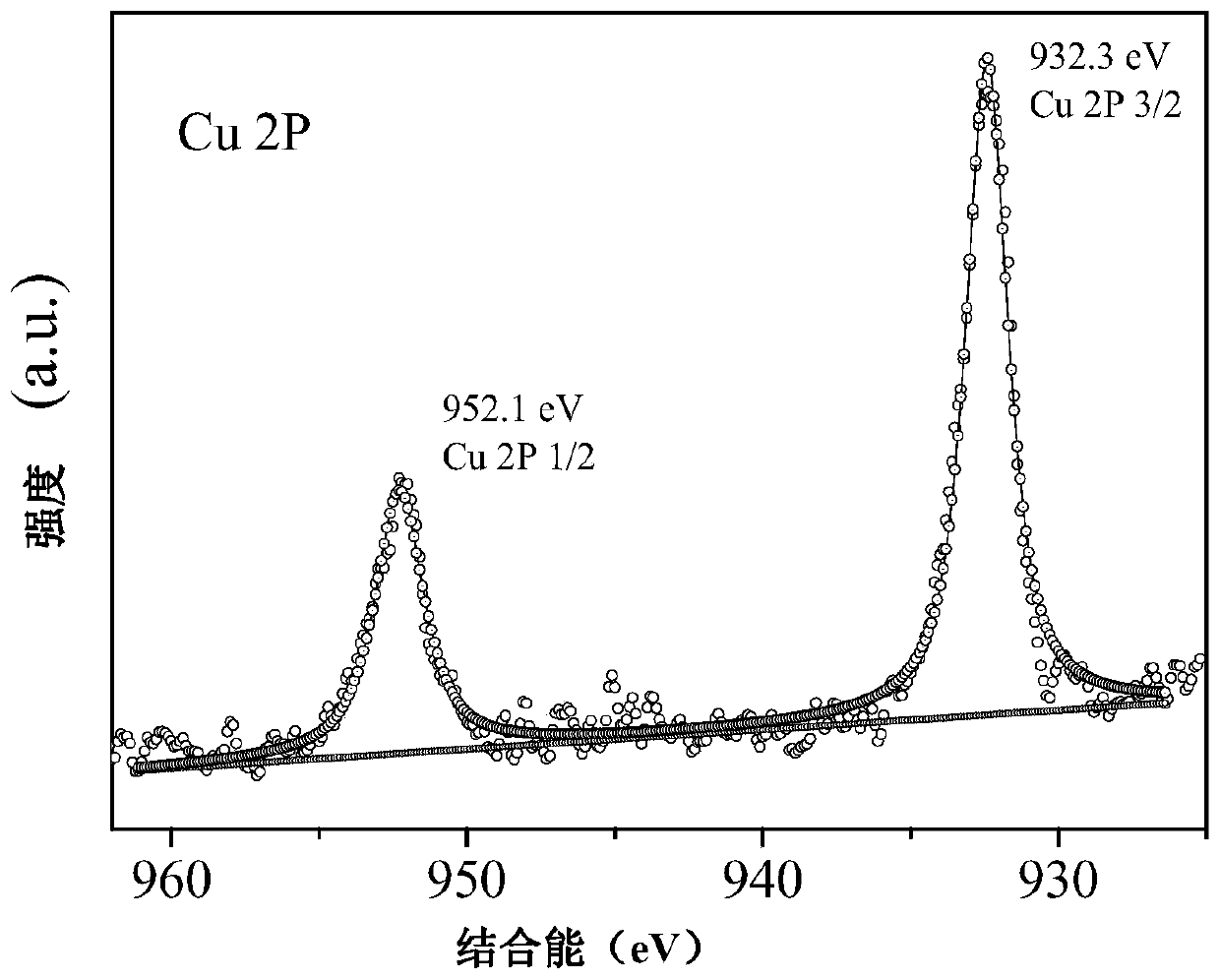

[0080] A kind of highly dispersed Cu / Ti involved in this embodiment 3 C 2 T x The preparation method of catalyst material comprises the steps:

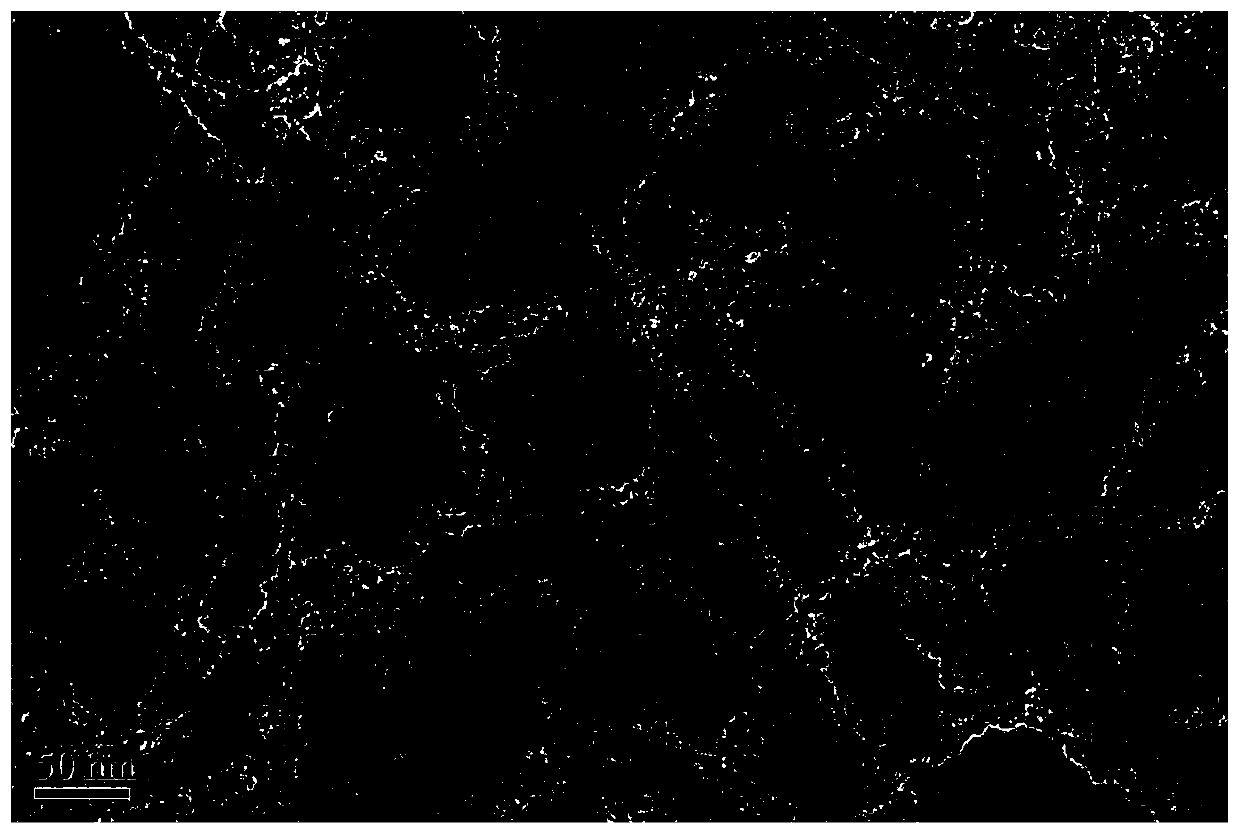

[0081] Step 1: Ti in a PTFE lined with a stir bar 3 C 2 T x Synthesis of two-dimensional carrier: Mix HCl and 3.6g lithium fluoride evenly in a water bath at 37°C, and stir for 0-30min. A certain quality of Ti 3 AlC 2Slowly added to it (Ti 3 AlC 2 : the mass ratio of lithium fluoride is 1:0.6, the mass ratio of lithium fluoride to acid is 1:6, the concentration of hydrochloric acid is not fixed, and other acids or mixed acids can also be used instead of hydrochloric acid), stirred for 5h, and made to fully react. Wash by centrifugation with deionized water and collect the precipitate until the supernatant is neutral. After adding water, use an oscillator to vibrate for 30 minutes to further expand the distance between material layers. Finally, use 10 minutes of time to use 180W power to ultrasonically help the material to s...

Embodiment 2

[0095] A kind of Cu / Ti that present embodiment relates to 2 CT x The preparation method of catalyst material comprises the steps:

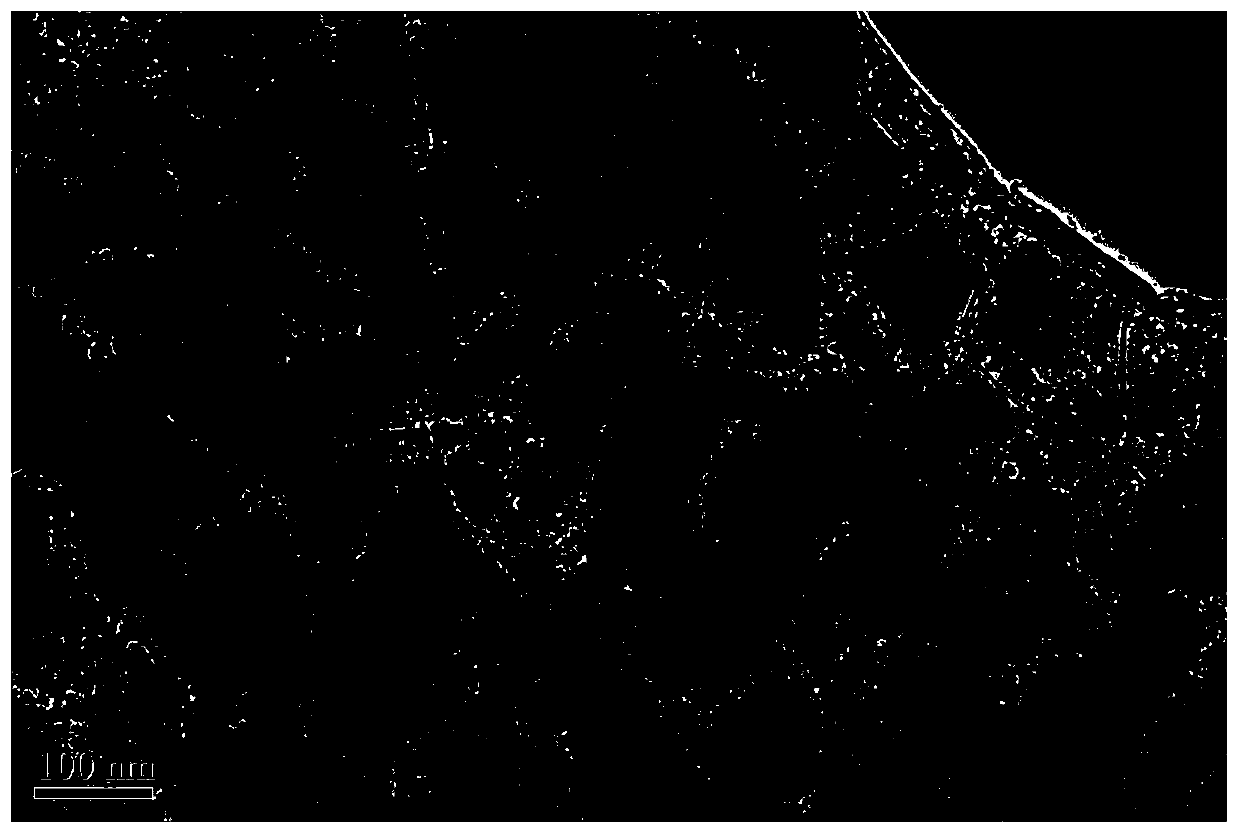

[0096] Step 1: Ti in a Teflon-lined (or plastic bottle) equipped with a stir bar 2 CT x Synthesis of the two-dimensional carrier: HCl and a certain mass of lithium fluoride were evenly mixed in a water bath at 20°C, and stirred for 60 minutes. Ti 2 AlC is slowly added to it, Ti 3 AlC 2 : The mass ratio of lithium fluoride is 1:1.6, the mass ratio of lithium fluoride to HCl is 1:20, stirred for 36h, and fully reacted. Wash by centrifugation with deionized water and collect the precipitate until the supernatant is neutral. After adding water, use an oscillator to vibrate for 1200 minutes to further expand the material layer spacing, and then use 60 minutes of time to use 80W power ultrasonic to help the material to stratify. After centrifugation to help the material to stratify, a single layer of Ti can be obtained. 2 CT x Colloidal solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com