An embedded spinning pipe and a method for selecting the specifications of the inner pipe of the embedded spinning pipe

A technology of laying tube and inner tube, used in metal rolling, metal processing equipment, bending workpieces, etc., can solve the problem of easy wear of the laying tube, avoid the influence of the normal production order of the factory, improve the service life, Increase the effect of over-steeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

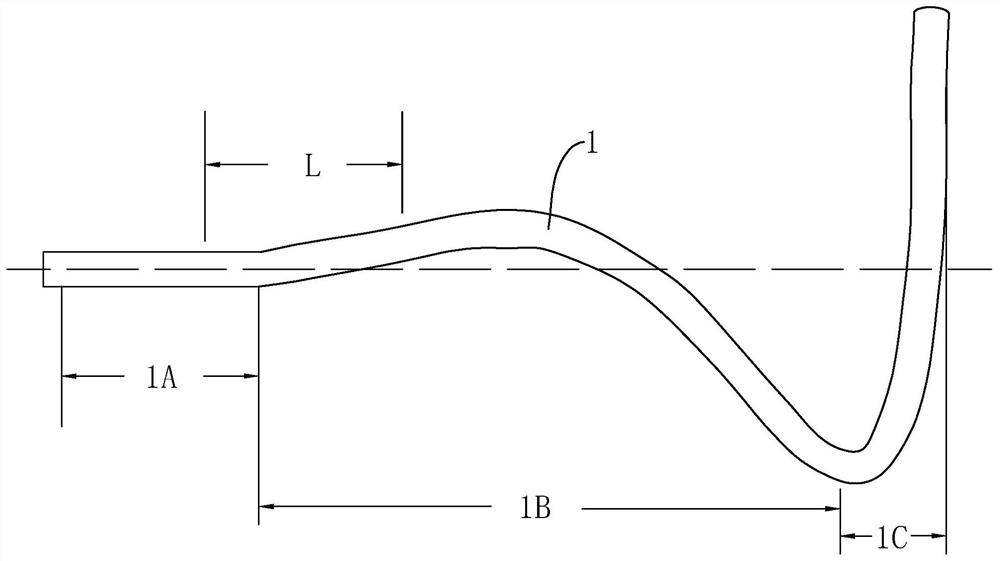

[0039] Embodiment: a kind of embedded type spinning pipe, as figure 1 As shown, it includes an outer tube 1, and the outer tube 1 is sequentially arranged as a straight line introduction section 1A, a curved deformation section 1B and a stable section 1C along its input end to the output end, and the straight line introduction section 1A, the curved deformation section 1B and the stable section 1C are integrally formed . The material of the outer pipe 1 is a thermally stable material commonly used in existing single-layer spinning pipes, such as 10CrMo918.

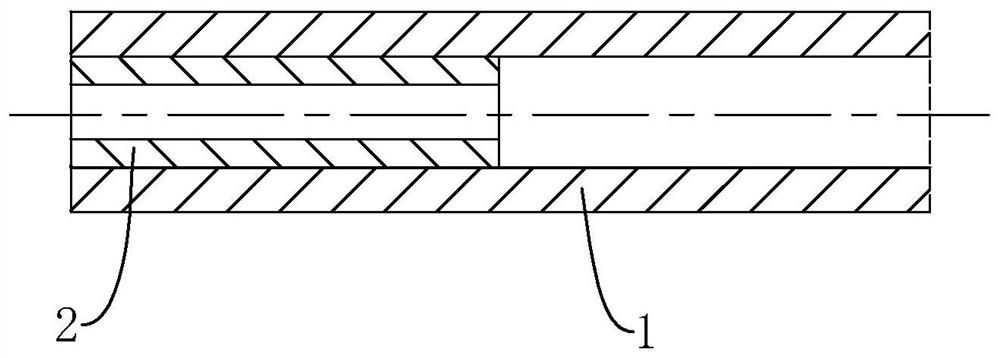

[0040] Such as figure 2 As shown, it also includes an inner pipe 2, the inner pipe 2 is a straight pipe made of wear-resistant material, and the wear-resistant material can be duplex stainless steel, high-speed steel, precipitation hardening stainless steel, high manganese steel, ductile iron, etc. The axial dimension of the inner tube is smaller than that of the outer tube, preferably 500-1000 mm; the inner tube 2 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com