A kind of antifreeze enhancer for slag base material and preparation method thereof

A base material and reinforcing agent technology, applied in the field of concrete, can solve the problems of easy freeze-thaw damage and poor frost resistance, and achieve the effects of improving the frost resistance effect, reducing the frost heave stress, and enhancing the crack resistance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

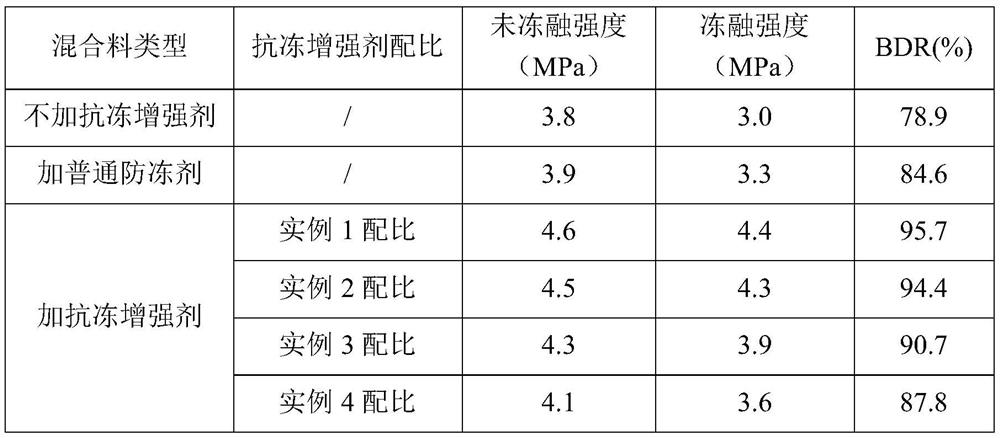

Examples

preparation example Construction

[0035] The present invention also provides a method for preparing a frost-resistant enhancer for slag-based base materials, which is used to prepare the above-mentioned frost-resistant enhancer for slag-based base materials, comprising the steps of:

[0036] uniformly mixing the pore filling and stress buffering components, the skeleton support component and the freezing point depression component to form a base material A, adding a reaction medium to the base material A, and continuously stirring to dissolve the base material A in the reaction medium to obtain a mixed solution, Then, let the mixture stand for 22-26h;

[0037] Heat the mixed solution to volatilize the reaction medium in the mixed solution to form the base material B, then add the early-strength improvement component to the base material B, and after mixing evenly, the base material for slag base can be obtained. antifreeze enhancer.

[0038] Specifically, adding a reaction medium to the base material A to ful...

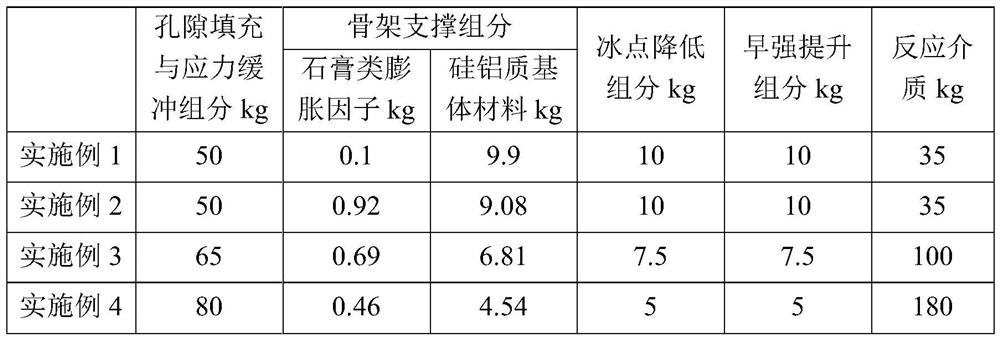

Embodiment 1

[0048] This embodiment provides a method for preparing a frost-resistant enhancer for slag-based base materials, and the specific steps are as follows:

[0049] Mix 50kg of superabsorbent resin, 0.1kg of natural dihydrate gypsum, 9.9kg of fly ash (that is, the mass ratio of gypsum expansion factor:silicon-aluminum base material is 1:99), and 10kg of ethylene glycol to form the base material A, add 35kg of distilled water to the base material A, and continue to stir to dissolve the base material A in the distilled water to obtain a mixed solution, and then leave the mixed solution for 22 hours;

[0050] Heat the mixture at 60°C for 600 minutes until the distilled water is completely volatilized to form base material B. Then, add 10kg of triethanolamine to base material B and mix well to obtain the antifreeze enhancer for slag-based base materials.

Embodiment 2

[0052] The difference between this embodiment and the above-mentioned embodiments is that the preparation method of the antifreeze enhancer for slag-based base materials provided by this embodiment, the specific steps are as follows:

[0053] Mix 50kg of superabsorbent resin, 0.92kg of natural dihydrate gypsum, 9.08kg of fly ash (that is, the mass ratio of gypsum expansion factor: silicon-aluminum base material is 10:99), and 10kg of ethylene glycol to form a base material A, add 35kg of distilled water to the base material A, and continue stirring to dissolve the base material A in the distilled water to obtain a mixed solution, and then leave the mixed solution for 26 hours;

[0054] Heat the mixture at 60°C for 600 minutes until the distilled water is completely volatilized to form base material B. Then, add 10kg of triethanolamine to base material B and mix well to obtain the antifreeze enhancer for slag-based base materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com