Anti-coking asphalt oxidation tower

A technology of oxidation tower and asphalt, which is applied in the direction of chemically processing tar asphalt/petroleum asphalt/natural asphalt, etc., which can solve the problem of uneven contact area between distributor and air, easy deposition of materials at the bottom of the tower body, and it is difficult to completely Contact and other problems, to achieve the effect of improving the oxidation effect, good oxidation effect, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

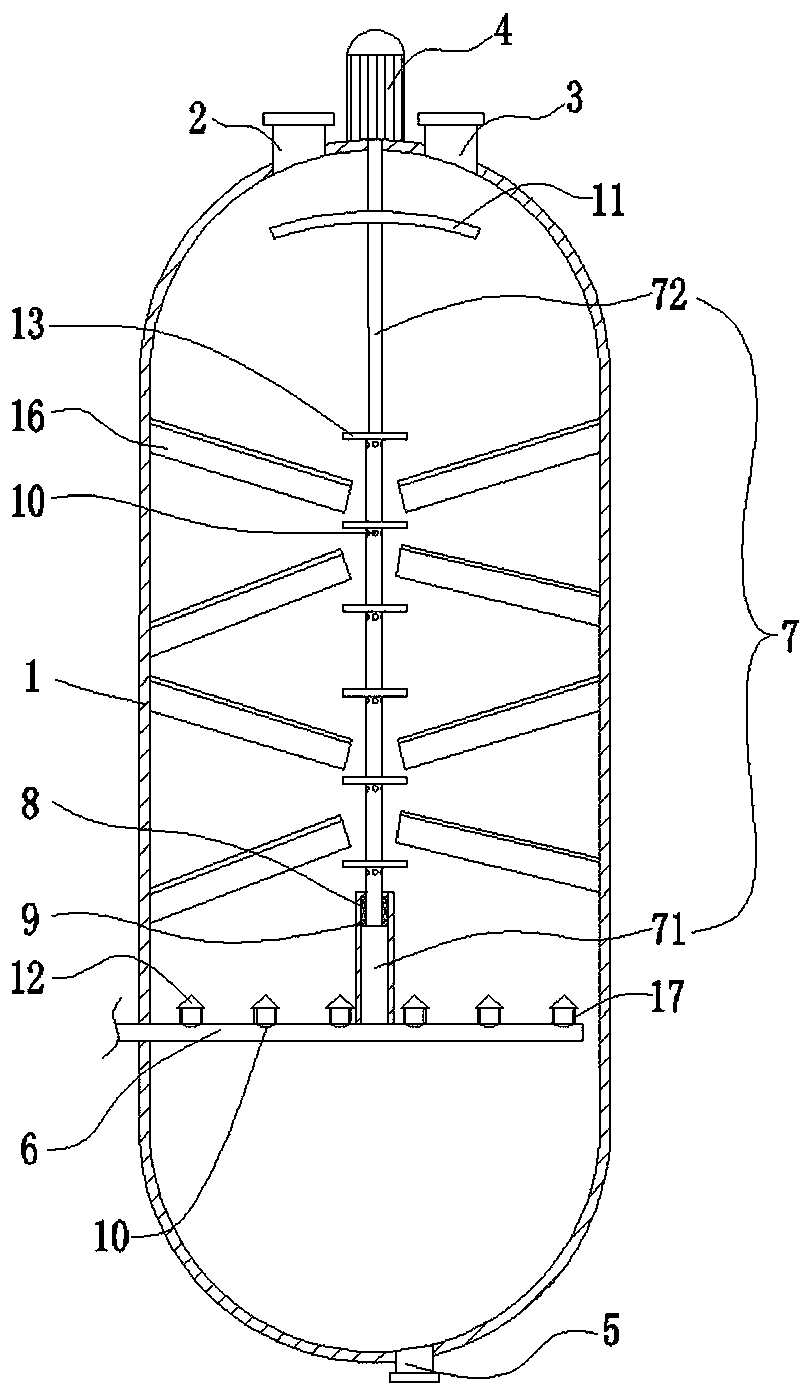

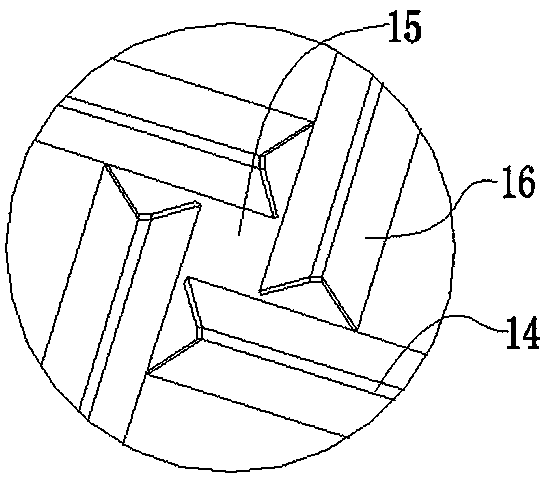

[0025] refer to figure 1 , figure 2 and image 3 As shown, an anti-coking asphalt oxidation tower includes a tower body 1, an air inlet distributor, an asphalt distributor 11, an anti-coking device and an oxidized asphalt disperser.

[0026] Wherein, an asphalt feed port 2 and an exhaust port 3 are provided on the top of the tower body 1 , a motor 4 is provided on the top of the tower body 1 , and an oxidized asphalt outlet 5 is provided at the bottom of the tower body 1 . Of course, the outer surface of the tower body 1 is also provided with a heating structure for heating the asphalt, which is a known technology and will not be repeated here.

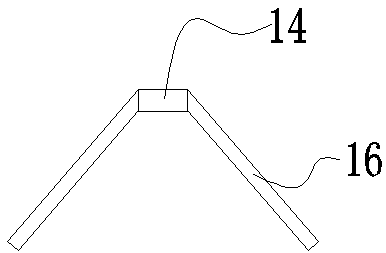

[0027] The above-mentioned air inlet distributor includes a horizontal air inlet pipe 6 and a vertical air inlet pipe 7 inside the tower body 1, wherein the horizontal air inlet pipe 6 is a plurality of cross-connected structures, such as forming a rice-shaped structure, and the vertical air inlet pipe 6 is a cross-connected struct...

Embodiment 2

[0032] The horizontal air inlet pipe 6 has a spiral structure, and the air outlets 10 are uniformly arranged on the horizontal air inlet pipe 6 . The spiral structure can make the compressed air evenly enter the tower body 1, distribute evenly, and oxidize evenly.

[0033]In addition, at least one air outlet 10 is provided on the vertical air inlet pipe 7 between two adjacent baffles 14 , and the anti-coking disc 13 is arranged above the air outlet 10 . In this way, air outlets 10 can be provided in the spaces between adjacent two layers of baffles 14, so as to meet the requirements of air intake at different positions in the tower, and can fully oxidize asphalt at different positions. On the one hand, it can mix asphalt with air. On the other hand, by controlling the wind speed, the flow direction of asphalt can be changed, thereby reducing the falling speed of asphalt, increasing the contact area between asphalt and air, and improving the oxidation effect.

[0034] The disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com