Isobutene polymerization system and isobutene polymerization method

A technology of isobutene and superposition reaction, which is applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, biological raw materials, etc., can solve the problem of inability to produce isobutene superposition oil, and achieve the effect of reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

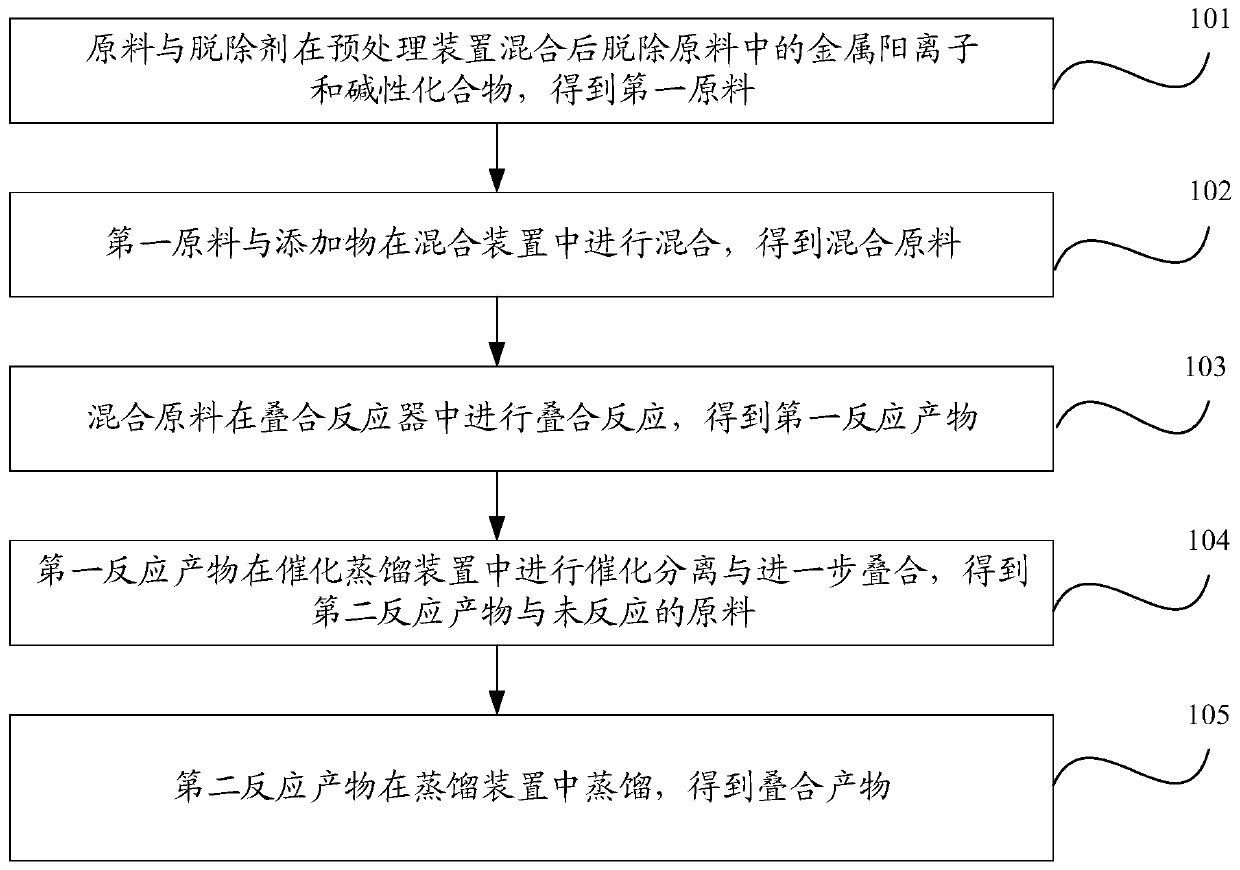

Method used

Image

Examples

Embodiment

[0147] An oil refinery originally had a MTBE unit with an output of 80,000 tons per year. The raw material for this unit was mixed C from the upstream gas separation unit. 4 raw material. mix C 4 The composition of raw materials is shown in Table 3. The feed rate is 32.82 tons / hour, and the annual processing capacity is 275,700 tons / year.

[0148] Table 3 Mix C 4 Raw material composition

[0149] serial number mix C 4 Raw material composition

quality score 1 C 3 h 6

0.0717 2 C 3 h 8

0.1231 3 NC 4 h 10

6.4405 4 IC 4 h 10

44.9512 5 NC 4 h 8

9.8830 6 IC 4 h 8

22.1794 7 TC 4 h 8

10.8297 8 CC 4 h 8

5.5203

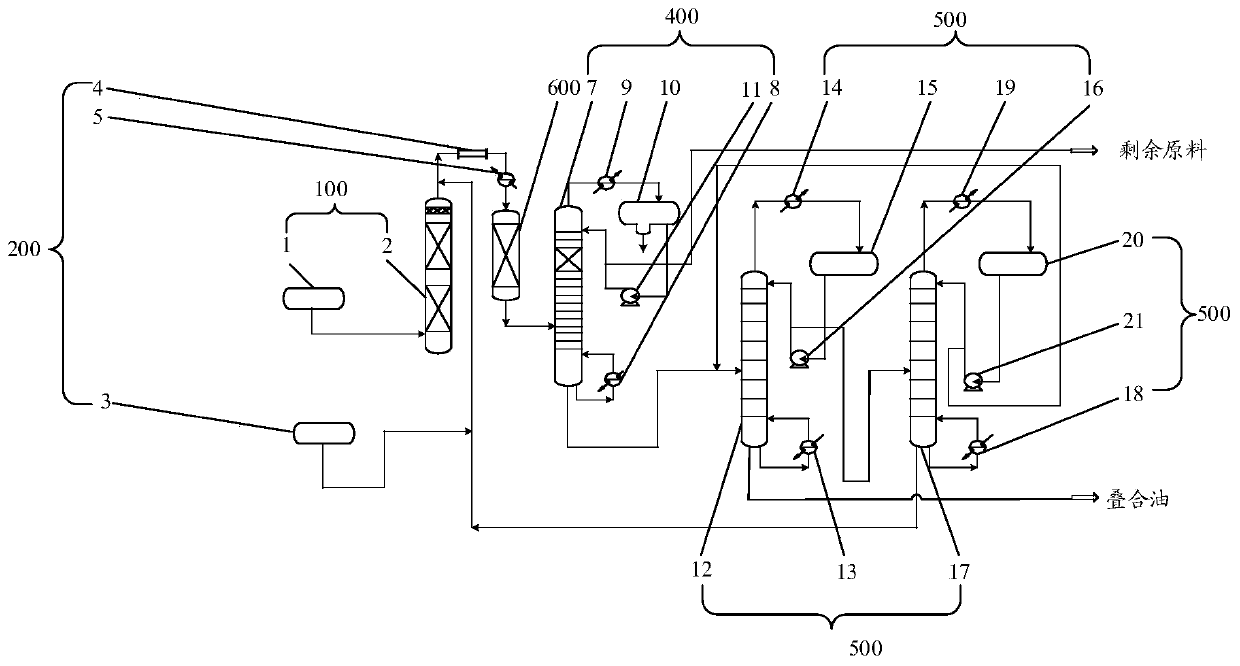

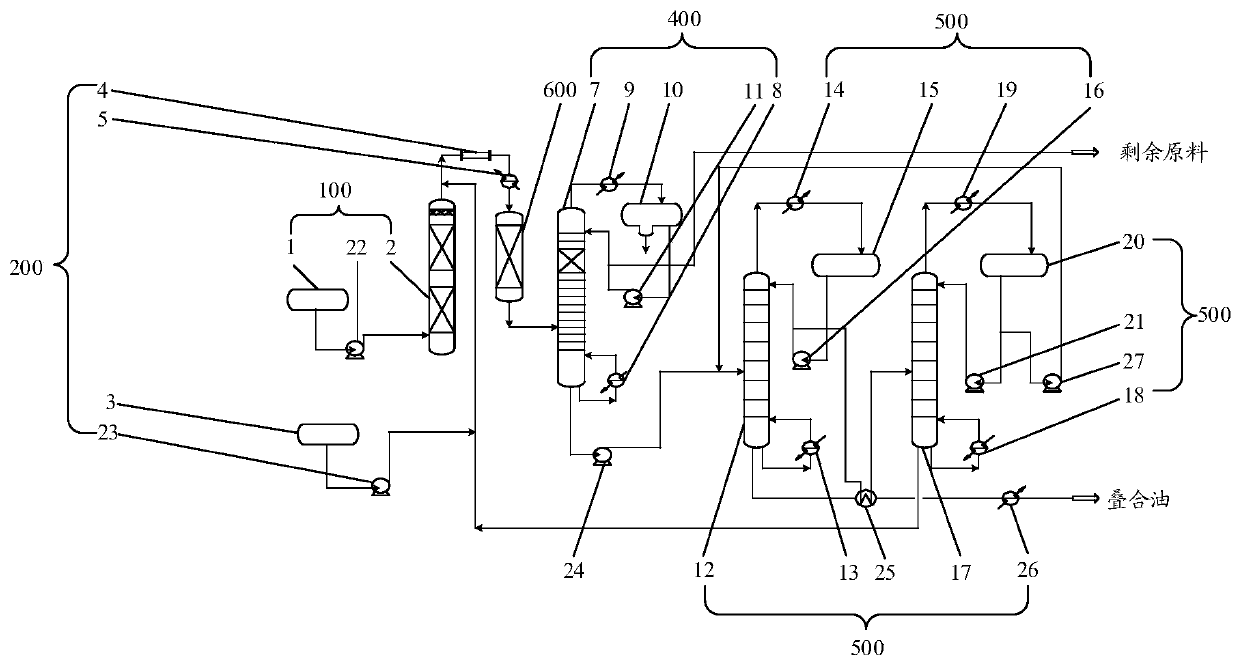

[0150] The main process flow of the isobutylene lamination system provided by the related technology is shown in Figure 4 : First mix the C4 raw material from the outside into the C4 raw material tank, use the C4 raw material pump to send the C4 raw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com