A plunger type digital pump

A plunger type, digital technology, applied in variable capacity pump components, pump control, pump components, etc., can solve the problems of complex control oil circuit, reduced mechanical efficiency, large external dimensions, etc., to achieve large application prospects and improve efficiency , no leakage and low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

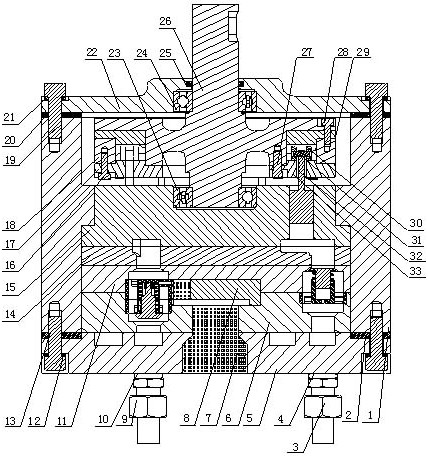

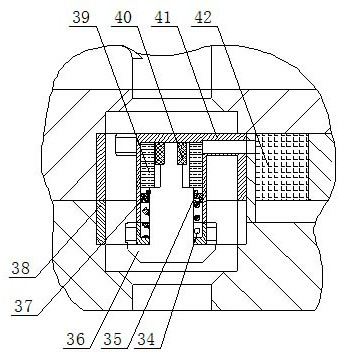

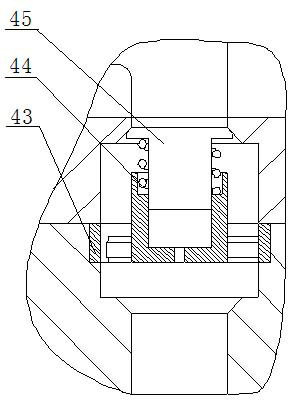

[0007] Such as Figure 1~Figure 4 As shown, the present invention is a plunger type digital pump, including a distribution end cover 5, a housing 1, a low-pressure valve body, a high-pressure valve body, a first cylinder 6, a second cylinder 8, a third cylinder 11, Fourth cylinder 14, fifth cylinder 15, roller plunger, first flow distribution slide 17, second flow distribution slide 29, third flow distribution slide 33, first sleeve 18, second sleeve 35, output The shaft 26, the first bearing 23, the second bearing 24 and the end cover 22, the roller plunger is installed in the fifth cylinder body 15, the fourth cylinder body 14 divides the plunger cavity into an oil suction passage and an oil pressure passage, the first cylinder Body 6 and the third cylinder body 11 are embedded with the second cylinder body 8, low-pressure valve body and high-pressure valve body, and the second cylinder body 8 is embedded with nine valve core controllers 42; Road 29, the third flow distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com