A wear-resistant semi-open solid-liquid two-phase flow pump impeller with detachable working surface

A working face, semi-open technology, applied in the field of fluid machinery, can solve the problems of high material cost, increased production cost, particle blockage and stuck, achieve simple connection and fixing method, low processing and manufacturing cost, and improve wear resistance performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

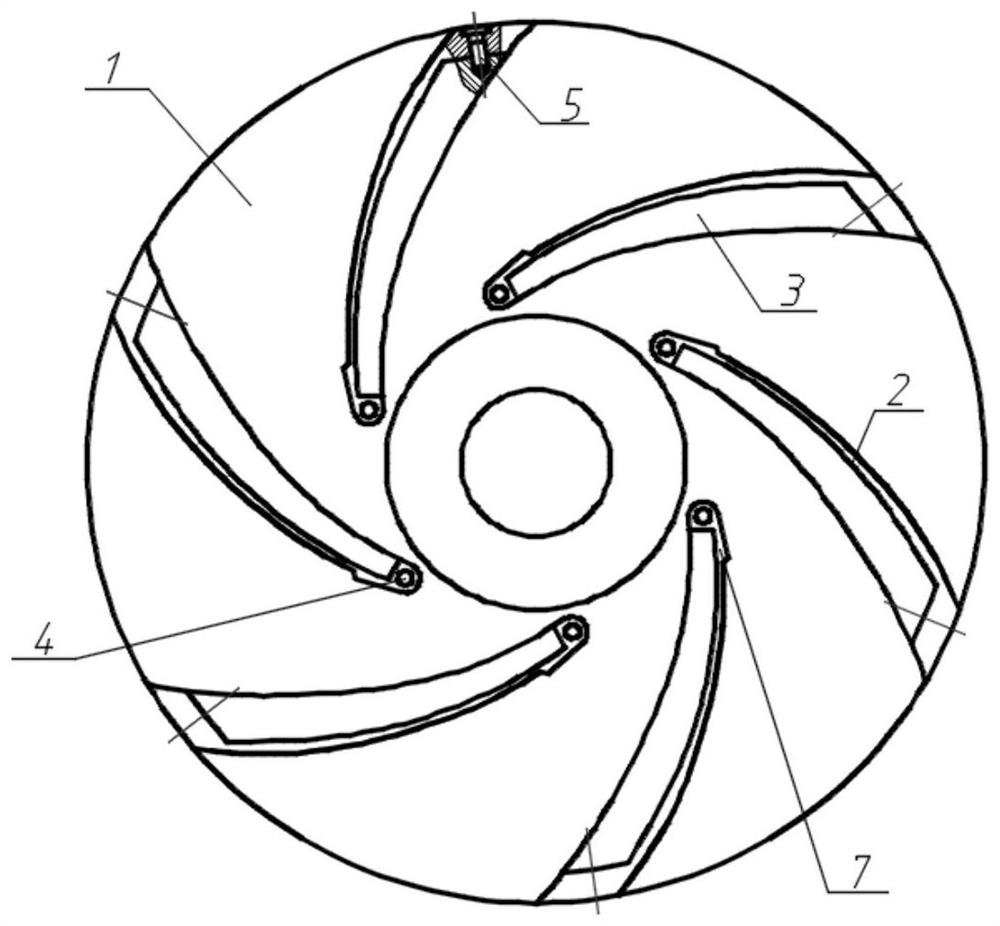

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, set threaded holes on the inlet end face and outlet end face of the basic blade 3 and the blade working surface lining plate 2 respectively, and then realize the connection between the basic blade 3 and the blade working surface lining plate 2 through screws, and then make the blade work The surface liner 2 is attached to the base blade 3, and it is more convenient to disassemble and replace.

Embodiment 2

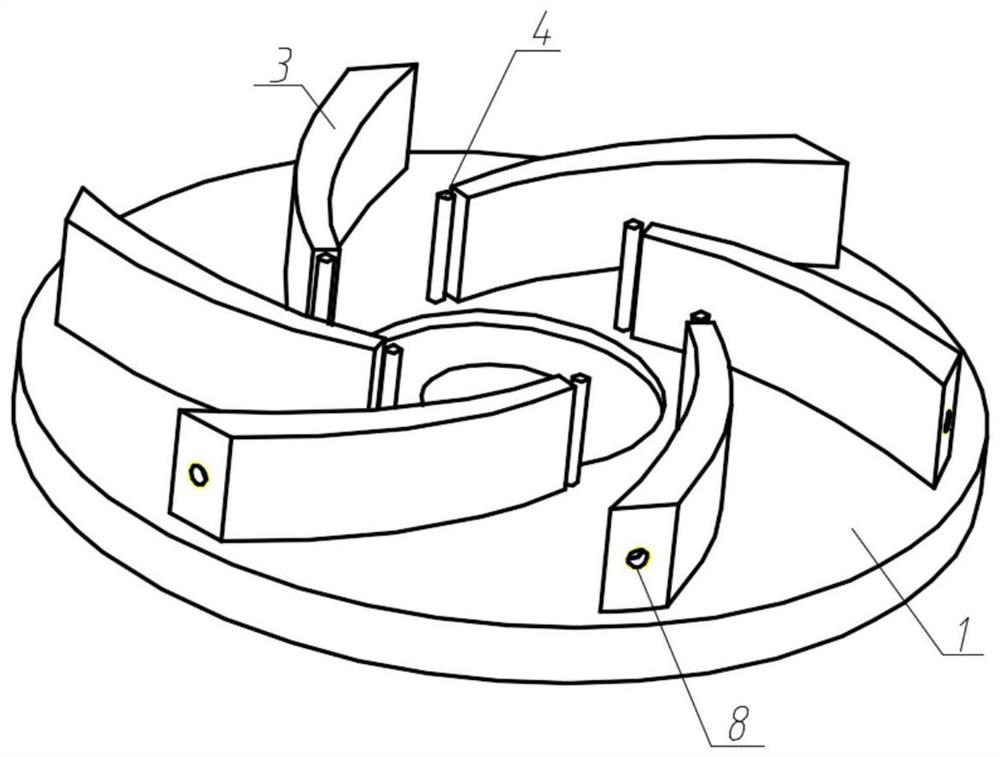

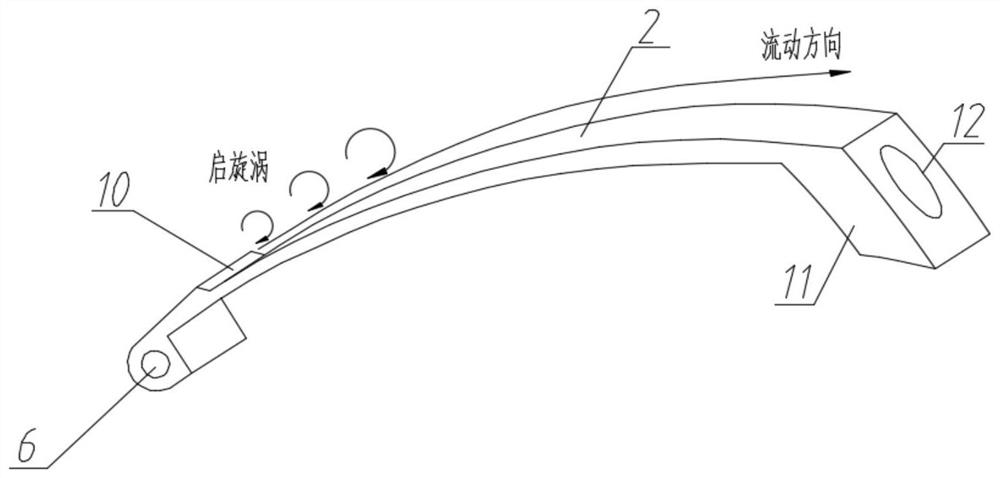

[0028] Embodiment 2, because it is necessary to disassemble the screws on the inlet end face and the outlet end face in Embodiment 1, which wastes working time, so a second design is proposed, that is, a cylindrical pin 4 is fixedly arranged at the front of the inlet end of each basic blade 3 such as figure 2 ; At the same time, there is a through hole 6 such as Figure 4 , the through hole 6 is perpendicular to the impeller rear cover plate 1, and the through hole 6 is matched with the cylindrical pin 4; as Figure 5 , a through hole 12 is opened on the end surface of the outlet end of the blade working surface liner 2, and a thread 7 is processed in the through hole 12. At the same time, a threaded hole 8 is also opened at the corresponding position of the basic blade 3, and the blade working surface lining plate is connected by a screw 5. 2. The outlet end face is connected with the outlet end face of the basic blade 3.

[0029] During installation, only two ends of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com