Nano calcium carbonate drying device

A technology of nano-calcium carbonate and drying equipment, applied in the direction of drying solid materials, non-progressive dryers, lighting and heating equipment, etc., can solve the problems of increasing the drying contact area and low drying efficiency of calcium carbonate, and achieve mechanical transmission maintenance Convenience, improvement of drying effect and reduction of equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

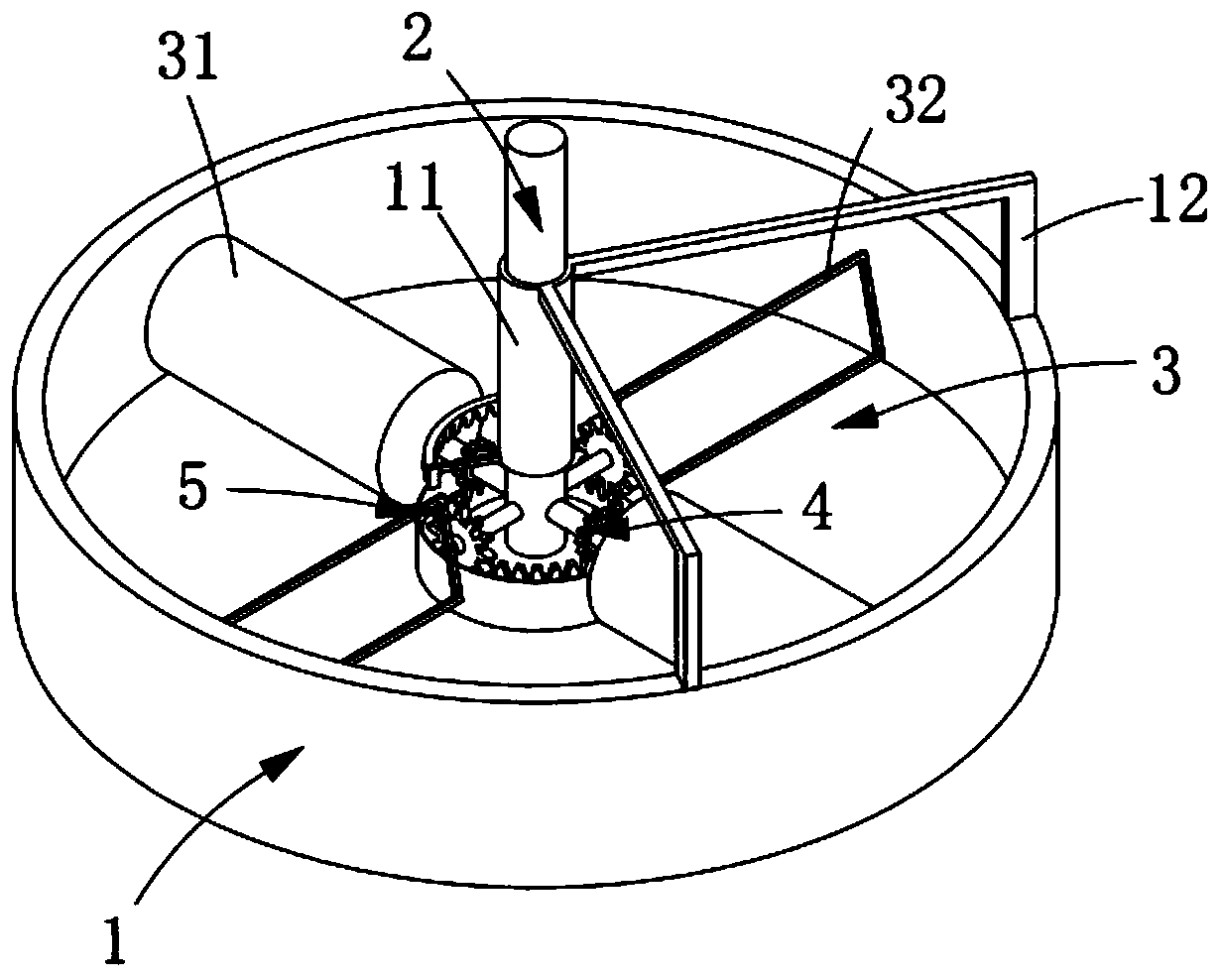

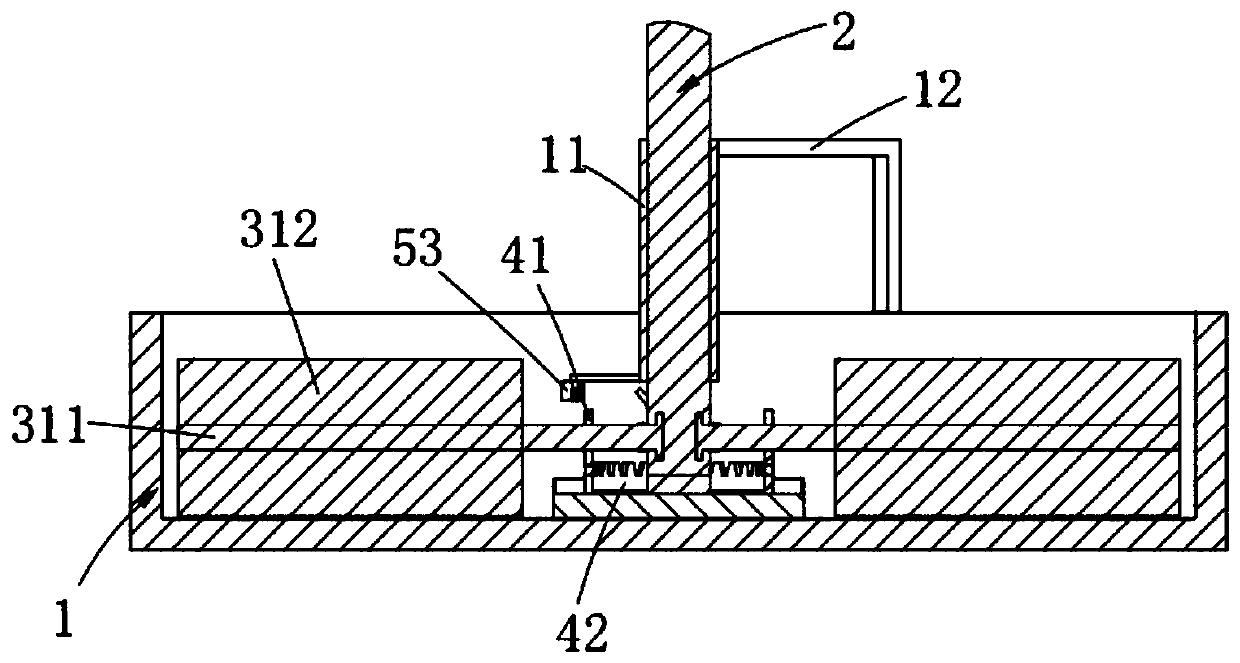

[0040] Such as figure 1 and 2 Shown, a kind of nano-calcium carbonate drying equipment, it comprises drying box 1, rotating shaft 2 and opening mechanism 3, and this drying box 1 is hollow and top opening is arranged; Described rotating shaft 2 is vertically arranged on described drying box 1 The middle part, and it is driven to rotate by an external driving device; the opening mechanism 3 is arranged on the bottom of the rotating shaft 2 in an array along the circumferential direction of the rotating shaft 2, and it rotates synchronously with the rotating shaft 2, and the opening Loose bodies 3 include:

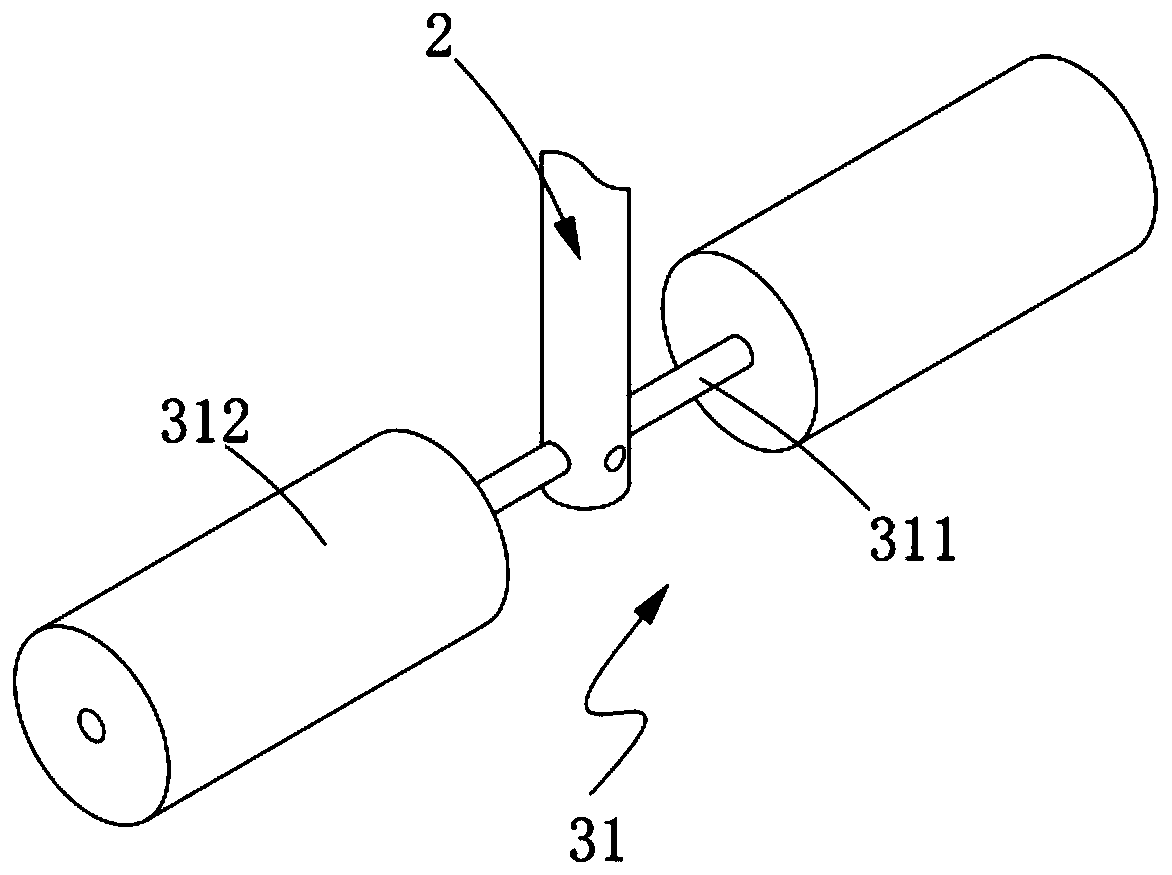

[0041] A rolling assembly 31, the rolling assembly 31 is rotatably arranged at the bottom of the rotating shaft 2 through the first transmission member 4, and it rolls the materials in the drying box 1; and

[0042] The loose component 32 is located behind the rolling component 31 along the rotation direction of the rotary shaft 2 , and is rotatably arranged at the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com