A precision aiming adjustment device for an optical alignment telescope

A technology for adjusting devices and telescopes, applied in the field of optical measurement, can solve the problems of unreliable fastening, poor stability and accuracy of optical alignment, poor versatility and flexibility, etc., and achieve good versatility, convenient operation, and adjustment of orientation And the effect of pitching convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following is a further detailed description of the contents of the invention in conjunction with the accompanying drawings and specific embodiments:

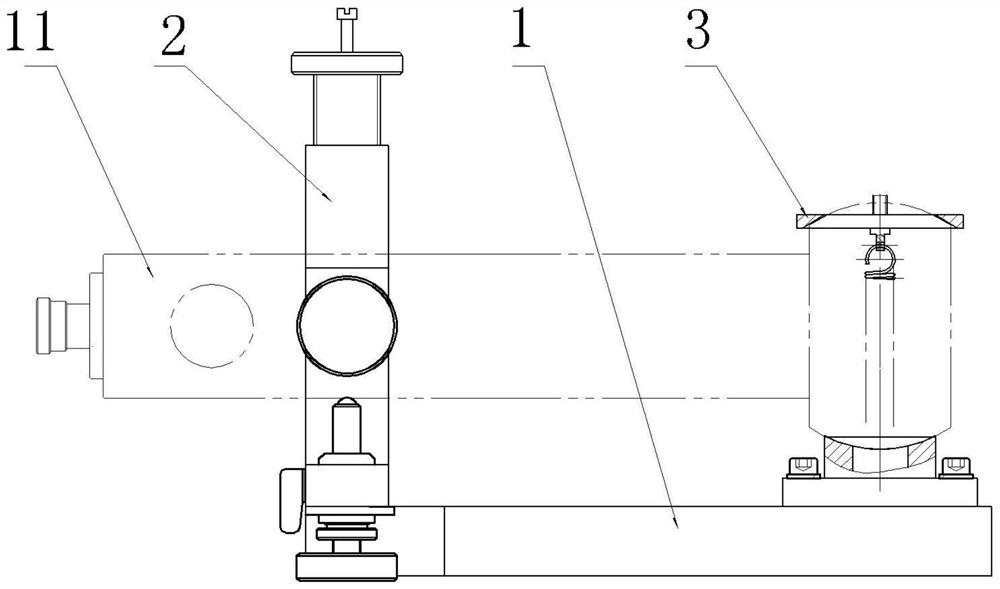

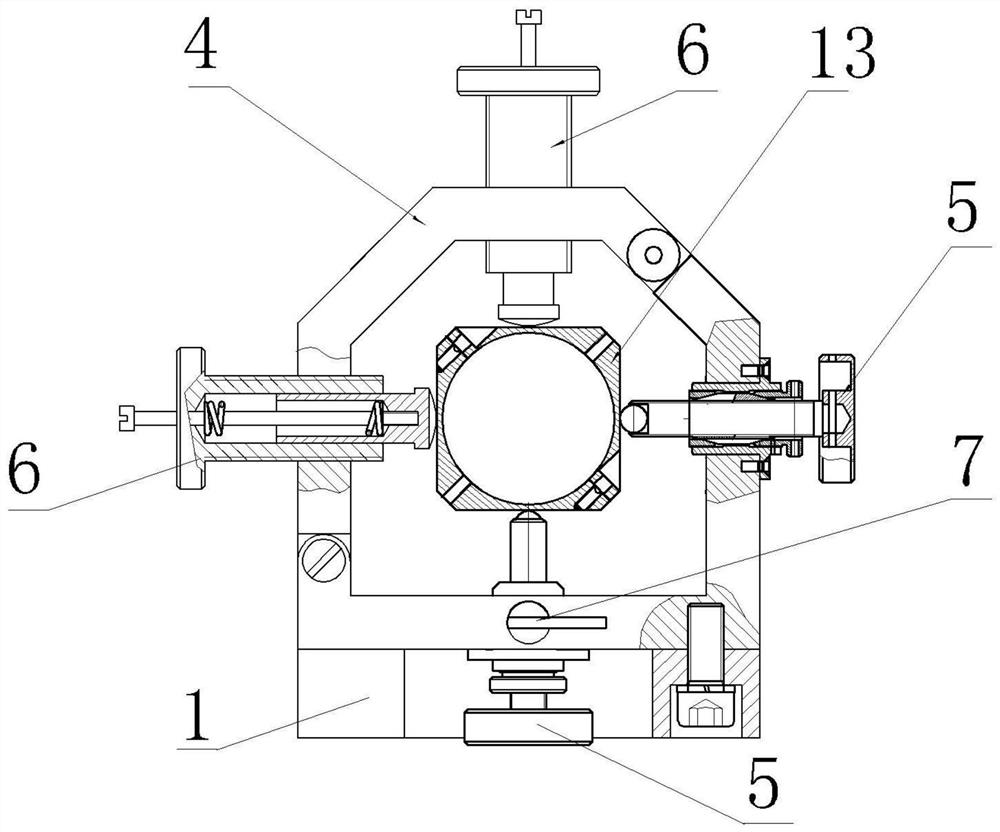

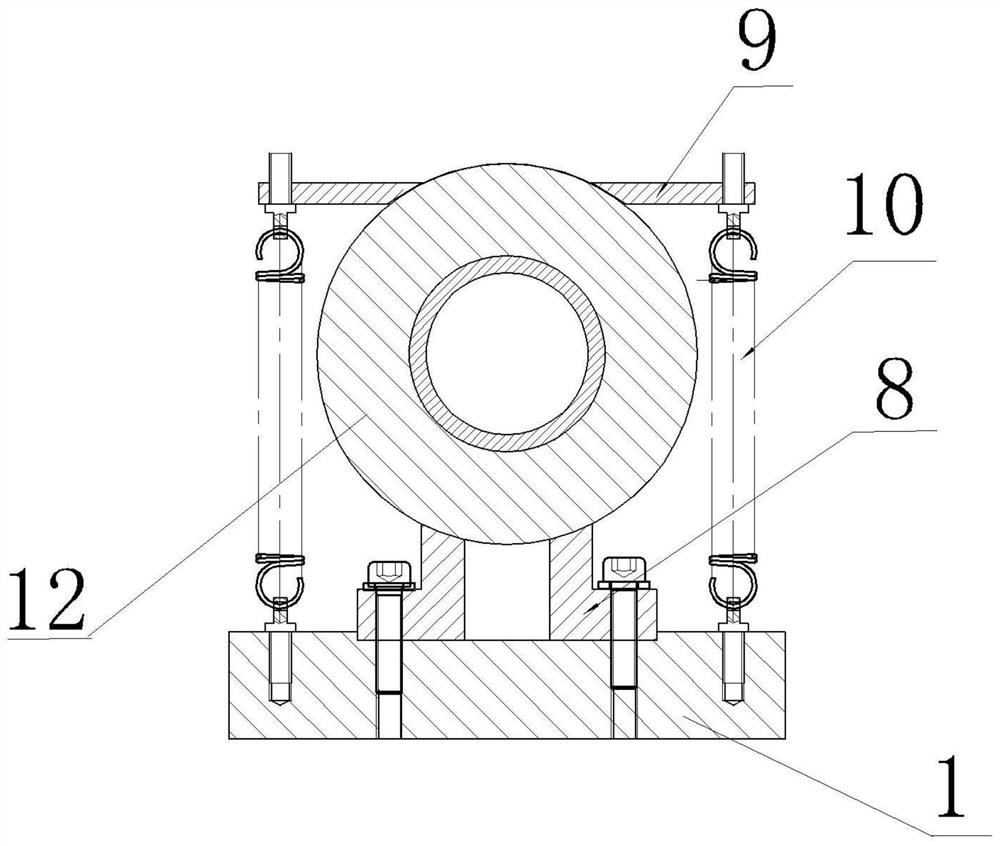

[0043] Such as Figure 1 to 5 As shown, a precision aiming adjustment device for optically quasi-line telescope includes a support bottom plate 1, a gantry clip mechanism 2, and a flexible fixing mechanism 3 for precision aiming to adjust the optical counseling telescope to adjust the optical counseling. The fixing mechanism 3 is disposed at both ends of the support bottom plate 1 for clamping and fastening to the optical coupling telescope 11.

[0044] Among them, a spherical access member 12 is attached to the front end of the optical counseling telescope 11, and the inner hole of the spherical access member 12 is coordinated with the mirror tube to be adjusted light, and the screw will be fixed; the rear end; Square auxiliary member 13, the inner hole of the square accessories 13 is mounted coaxially with the lens barre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com