An Arbitrary Waveform Optical Frequency Modulation and Source Tracing Device

An arbitrary waveform, acousto-optic modulator technology, applied in measurement devices, optics, optical components, etc., can solve the problems of difficult to achieve laser vibration measurement traceability, measurement calibration problems cannot be solved, and it is difficult to find devices and equipment. , to achieve the effect of solving dynamic measurement and quantity traceability problems, good adaptability and good convergence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

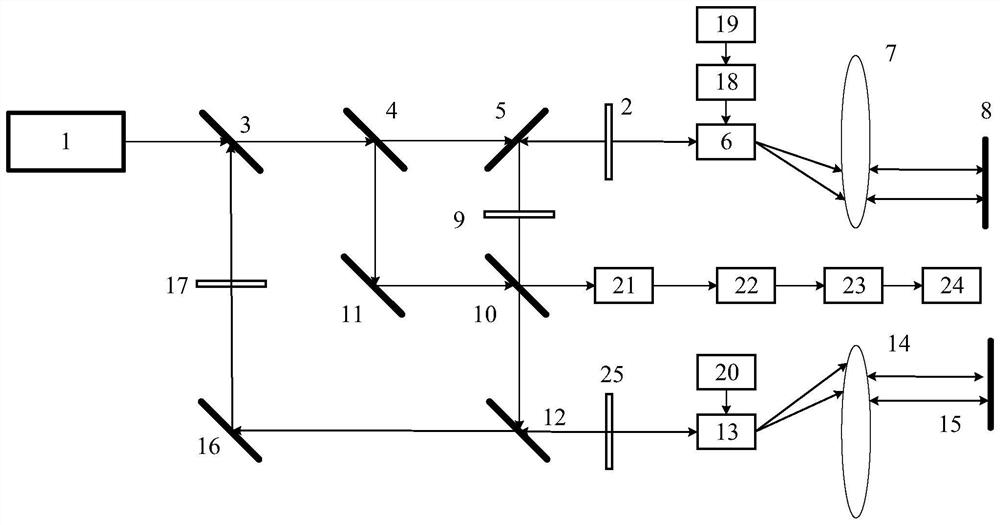

[0021] Such as figure 1 As shown, an arbitrary waveform optical frequency modulation and traceability device disclosed in this embodiment consists of a laser vibrometer 1, a first λ / 2 wave plate 2, a second λ / 2 wave plate 9, and a third λ / 2 wave plate Sheet 17, the fourth λ / 2 wave plate 25, the first polarization beam splitter 3, the second polarization beam splitter 5, the third polarization beam splitter 10, the fourth polarization beam splitter 12, the beam splitter 4, the first lens 7, the first polarization beam splitter Two lenses 14, first plane mirror 8, second plane mirror 11, third plane mirror 15, fourth plane mirror 16, first acousto-optic modulator 6, second acousto-optic modulator 13, FM signal source 18, arbitrary wave generator 19, sine signal source 20, photodetector 21, filter amplifier 22, digital oscilloscope 23, and electronic computer 24.

[0022] The laser light generated by the laser vibrometer 1 passes through the first polarizing beam splitter 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com