Crusher

A crusher and frame technology, applied in grain processing, etc., can solve the problems of different requirements for garbage crushing and affect the efficiency of garbage processing, and achieve the effects of shortening downtime and maintenance time, increasing the scope of application, and improving feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

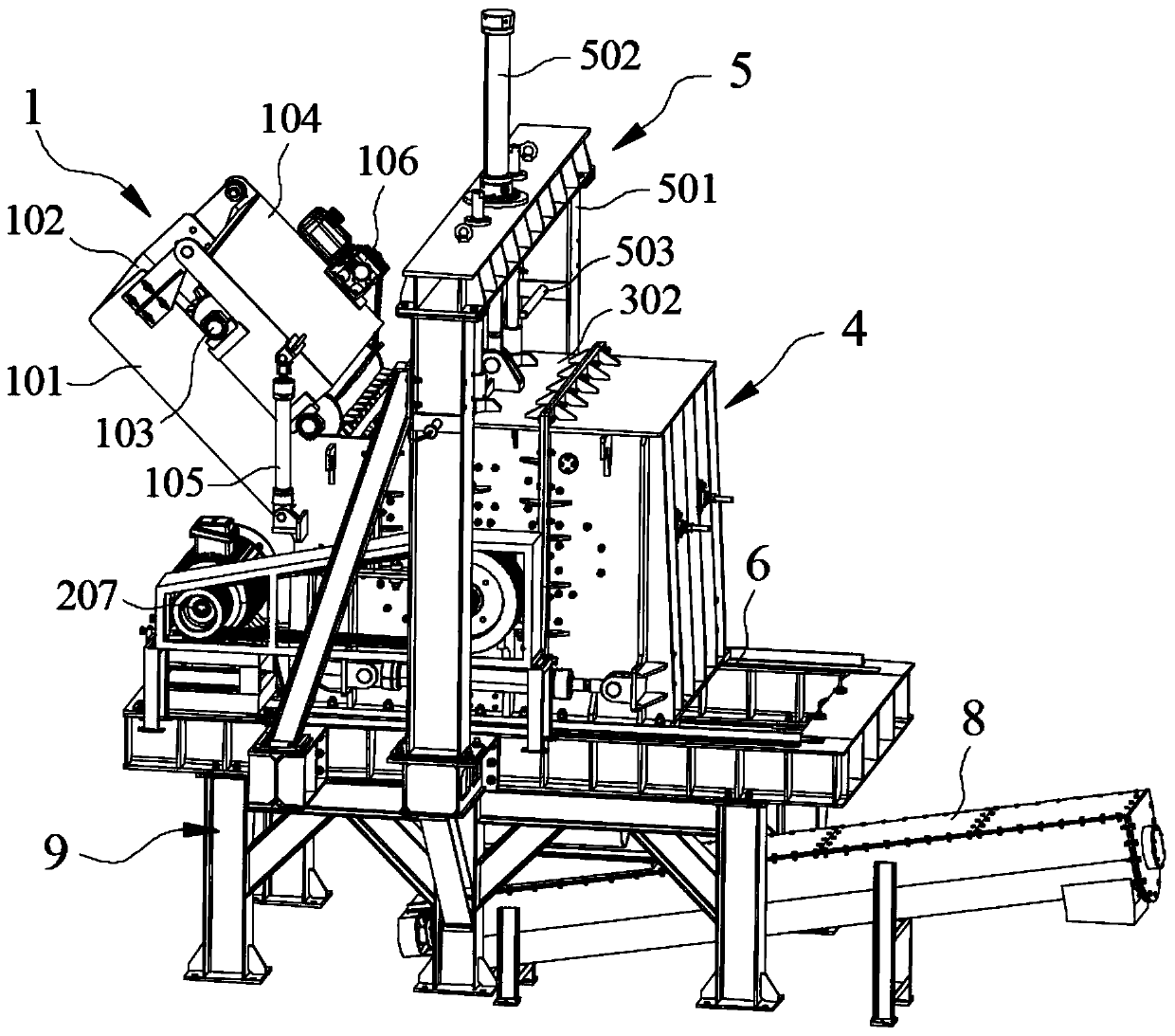

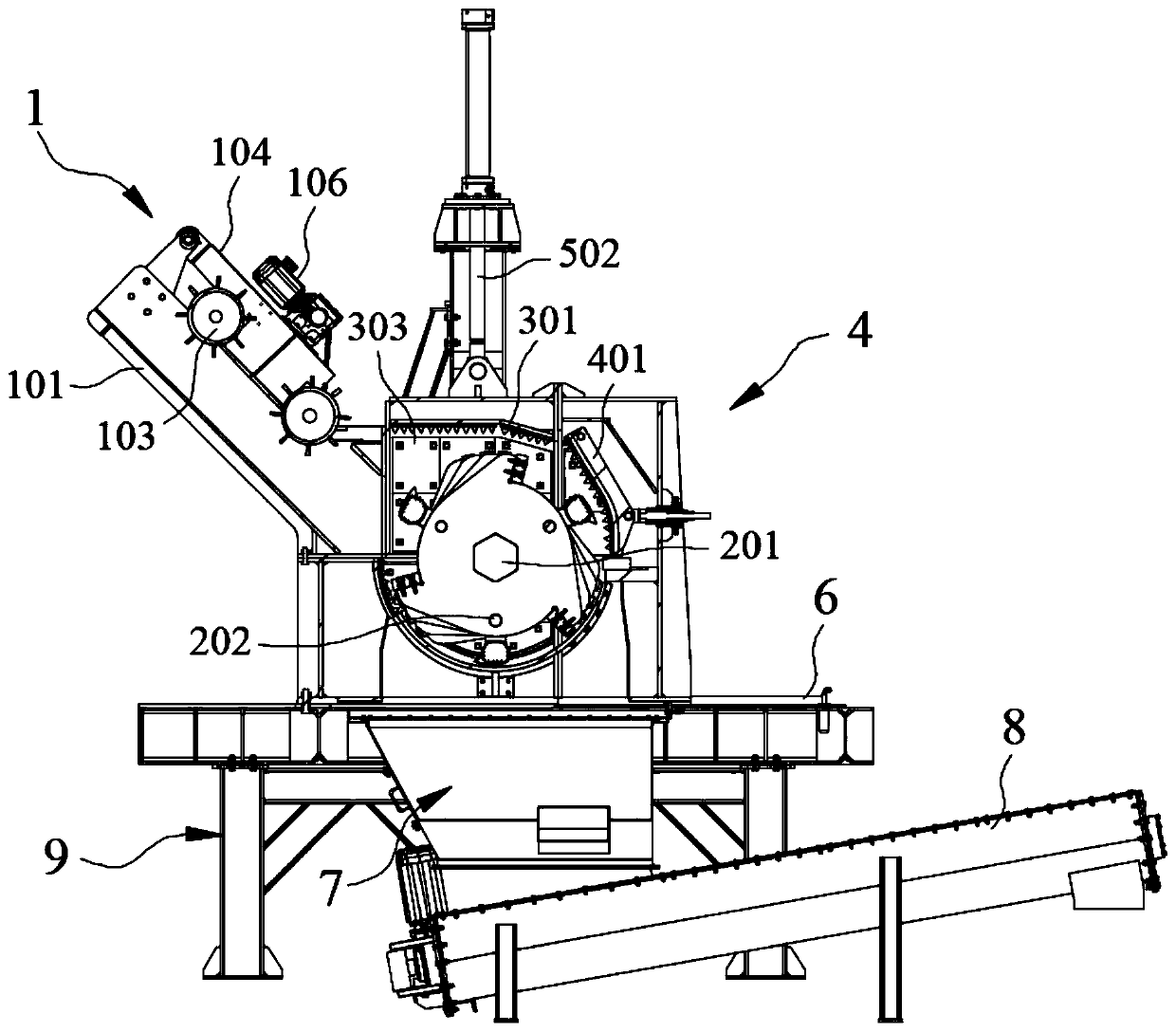

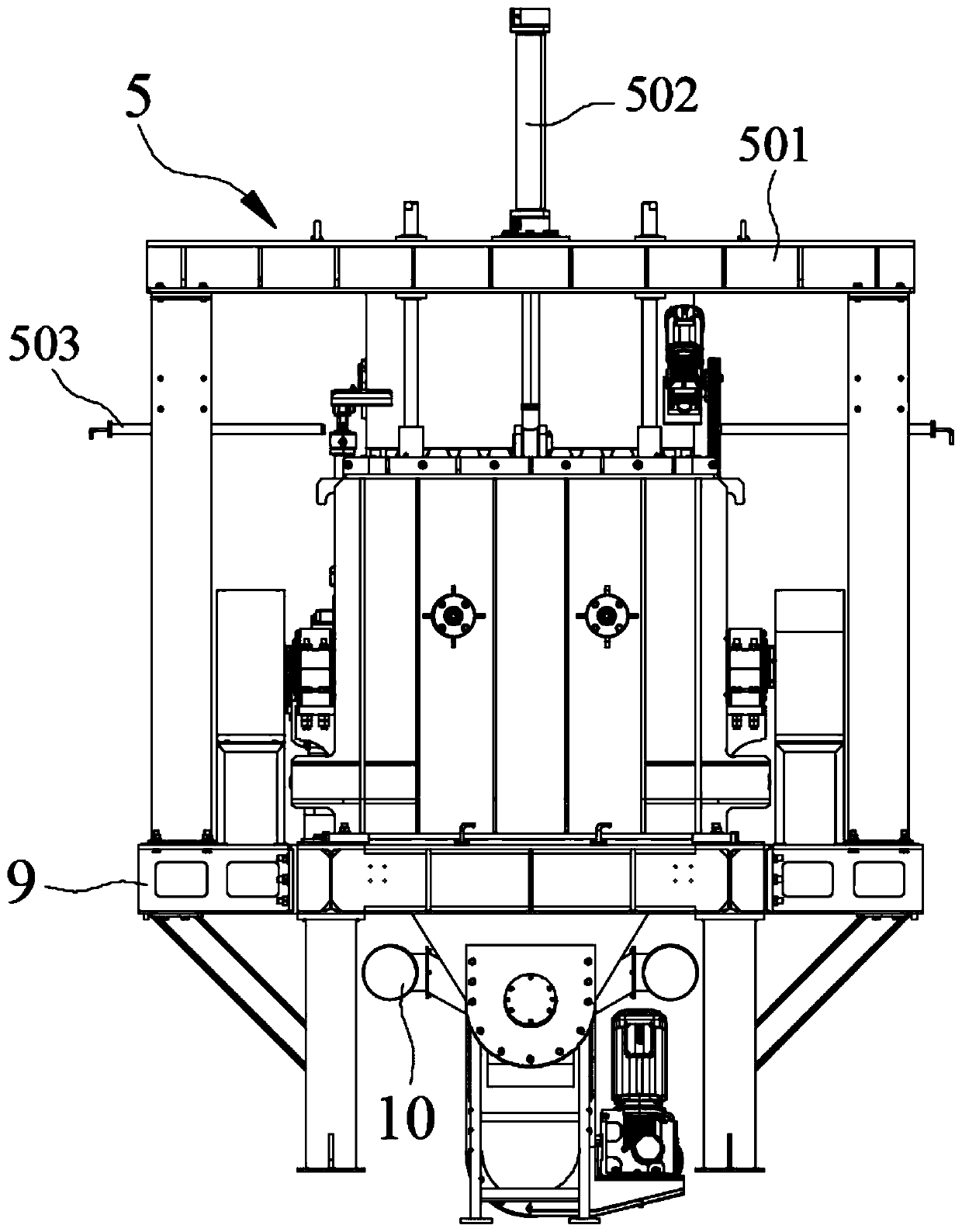

[0045] see Figure 1~3 , the crusher in the preferred embodiment of the present invention includes a frame 9 with a working platform and a feed part 1, a main shaft part 2, a first box 3, a second box 4 arranged on the working platform, and a main shaft arranged on the The sieve plate 11 and the lower hopper 7 below the component 2, and the screw conveyor 8 arranged below the lower hopper 7. The above-mentioned frame 9 is preferably arranged on the ground, that is, the setting height of the working platform is higher than the horizontal plane, and the materials to be crushed (such as household garbage) are fed to the first box body 3 and the second box body 4 after passing through the feeding part 1. In the resulting crushing box, the main shaft part 2 is used for crushing. After the crushed material is smaller than the size of the sieve hole on the sieve plate 11, it passes through the sieve plate 11 and is fed to the screw conveyor 8 through the lower hopper 7. The broken m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com