Ladle covering and uncovering device of LF and using method thereof

A technology of adding cover and furnace steel, applied in metal processing equipment, casting melt container, casting equipment, etc., can solve the problems of lower alloy yield, loss of molten steel temperature, rise of inclusions, etc., and improve the quality of casting billets. , The effect of saving molten steel heat preservation agent and reducing the tapping temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific structure of the present invention is explained in detail:

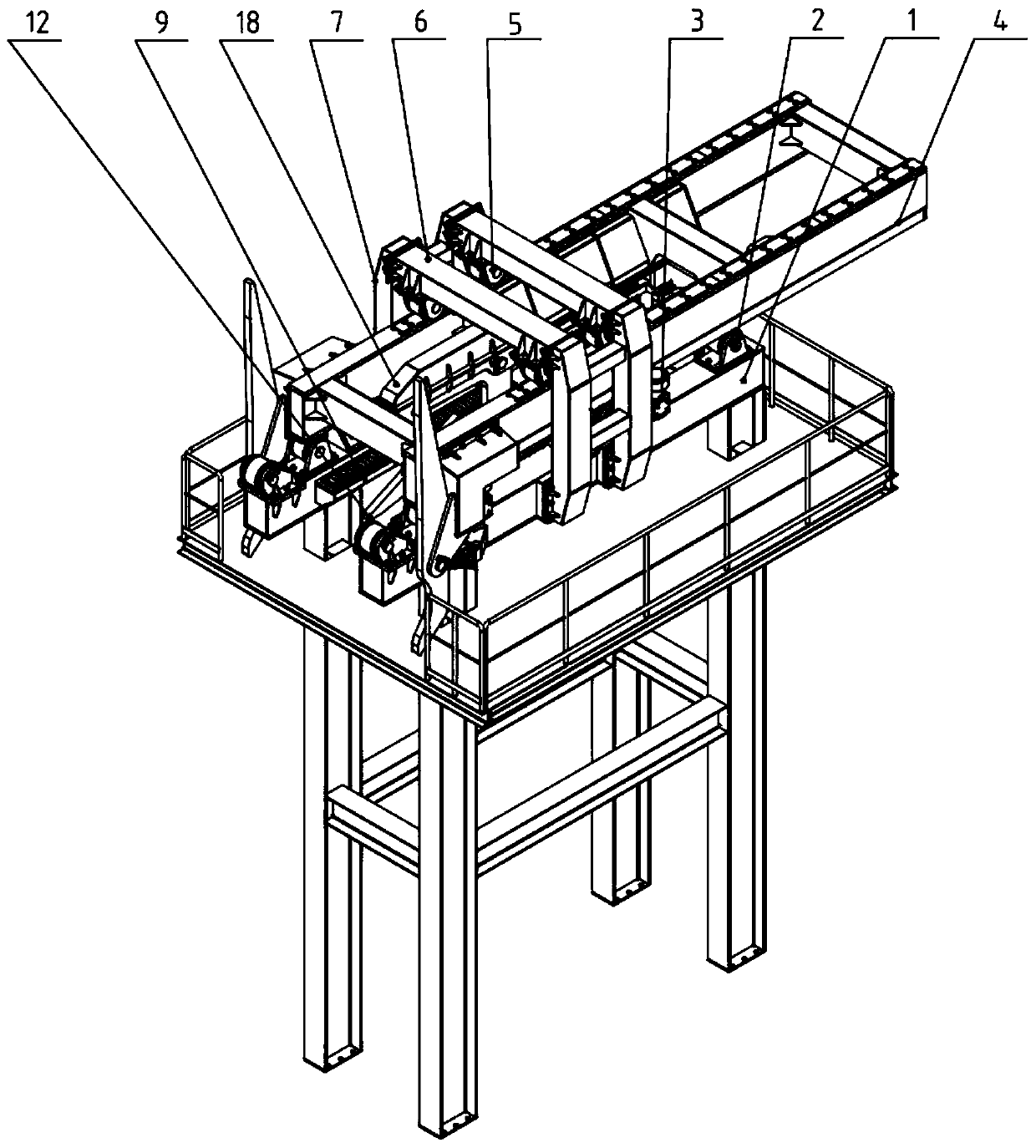

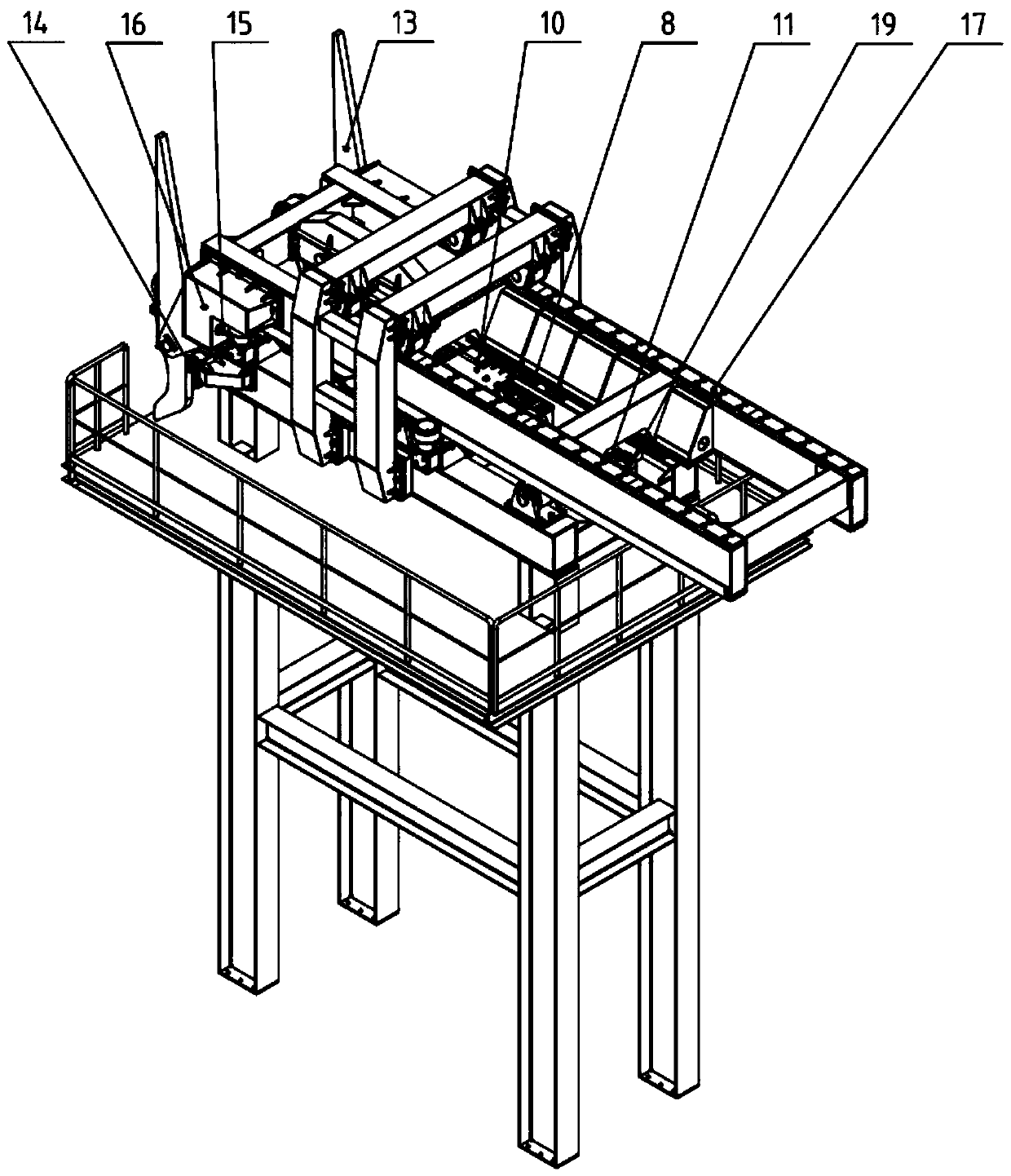

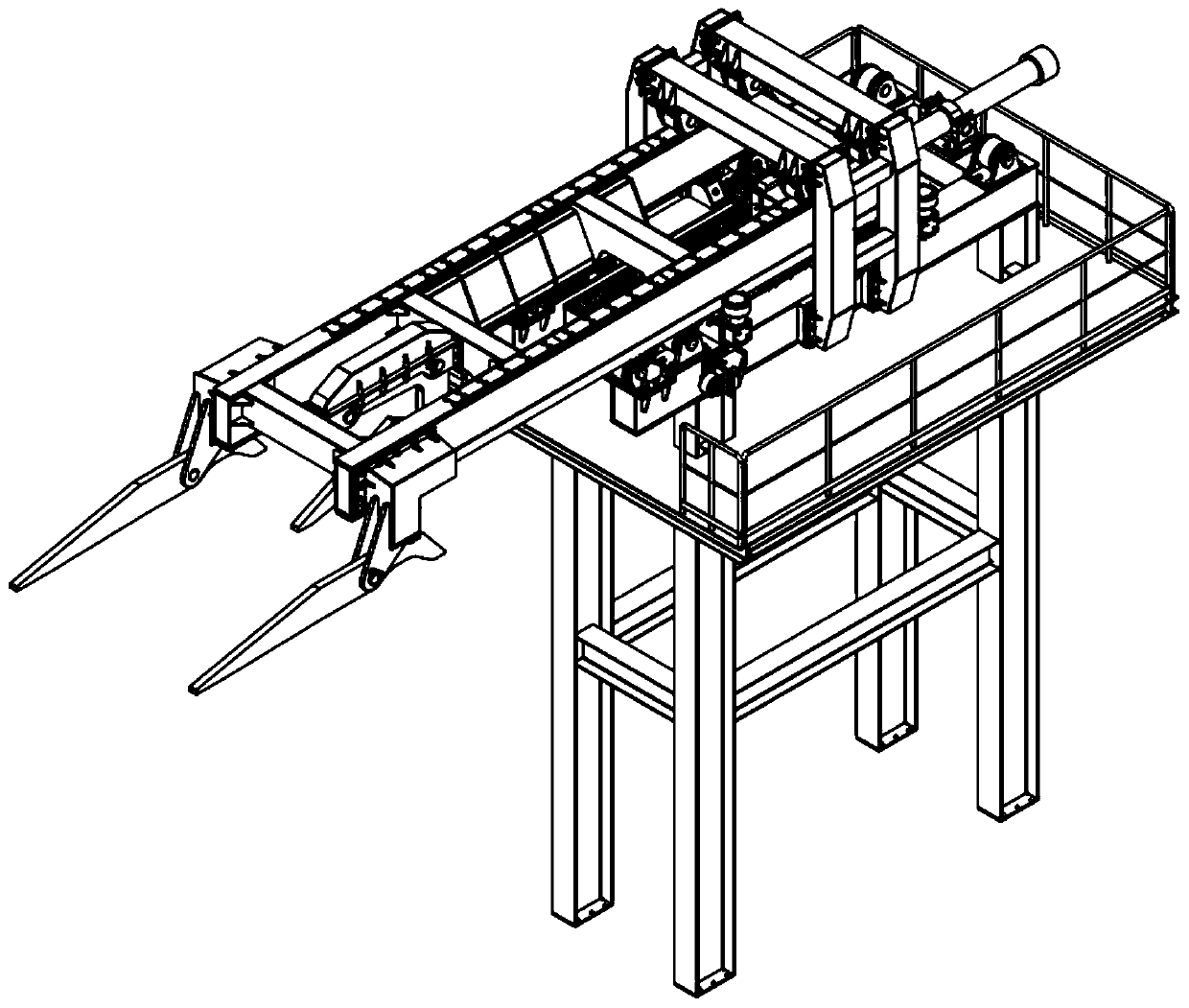

[0027] See Figure 1-Figure 6 , a kind of LF furnace steel ladle adding uncovering device, comprises fixed beam supporting mechanism, moving beam telescopic mechanism, drive mechanism, described moving beam telescopic mechanism reciprocates on fixed beam supporting mechanism, is provided with on described fixed beam supporting mechanism The fixed beam rack 9 is provided with the movable beam rack 8 on the movable beam telescopic mechanism. Gear rack 9, mobile beam rack 8 are meshed.

[0028] The fixed beam support mechanism includes a fixed beam 1, a moving beam supporting wheel 2, a moving beam side guide wheel 3, a supporting tooth guide wheel 14, a fixed beam rack 9, and a pressure wheel assembly. The fixed beam 1 is composed of two longitudinal The beam and several beams are welded into a box-shaped frame structure. The moving beam supporting wheel 2 and the moving beam side guide wheel 3 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com