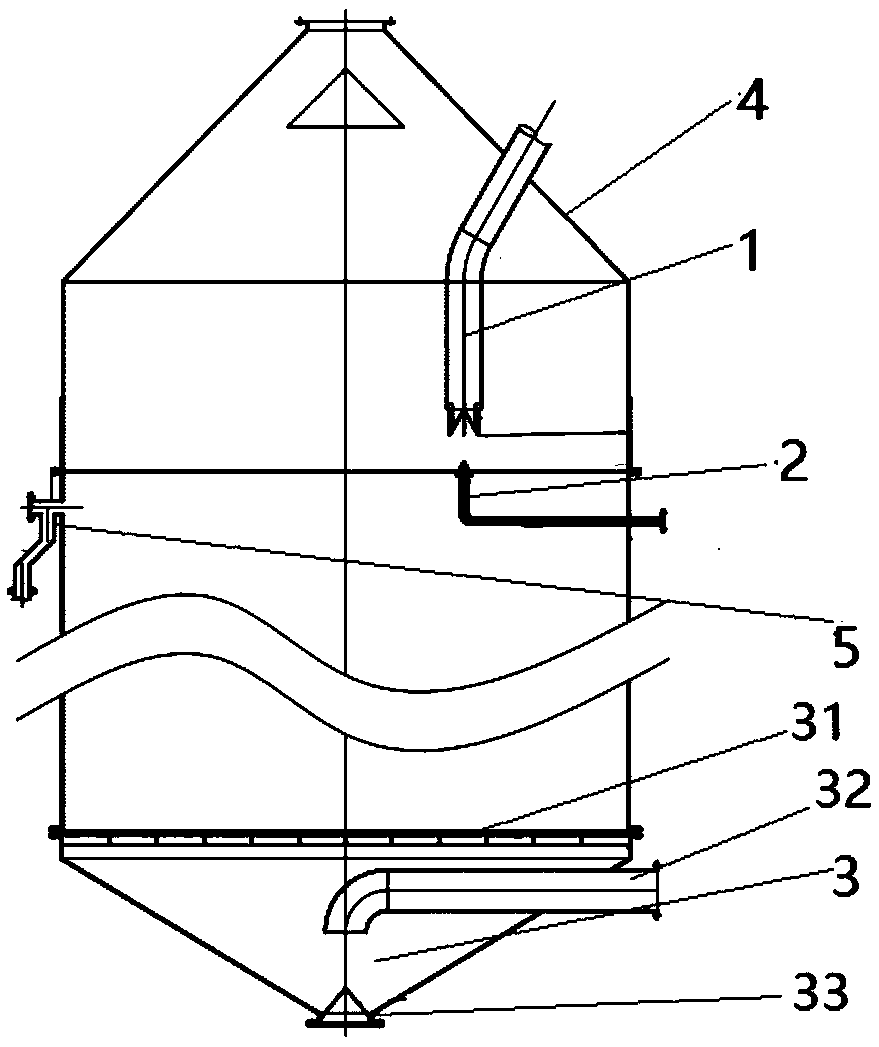

Gypsum calcinator and working principle

A calciner and gypsum technology, which is applied in the field of gypsum production equipment, can solve the problems of affecting the properties of powder materials, over-burning, and uneven distribution of powder materials, and achieve the effects of improving quality, avoiding local over-burning, and reducing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

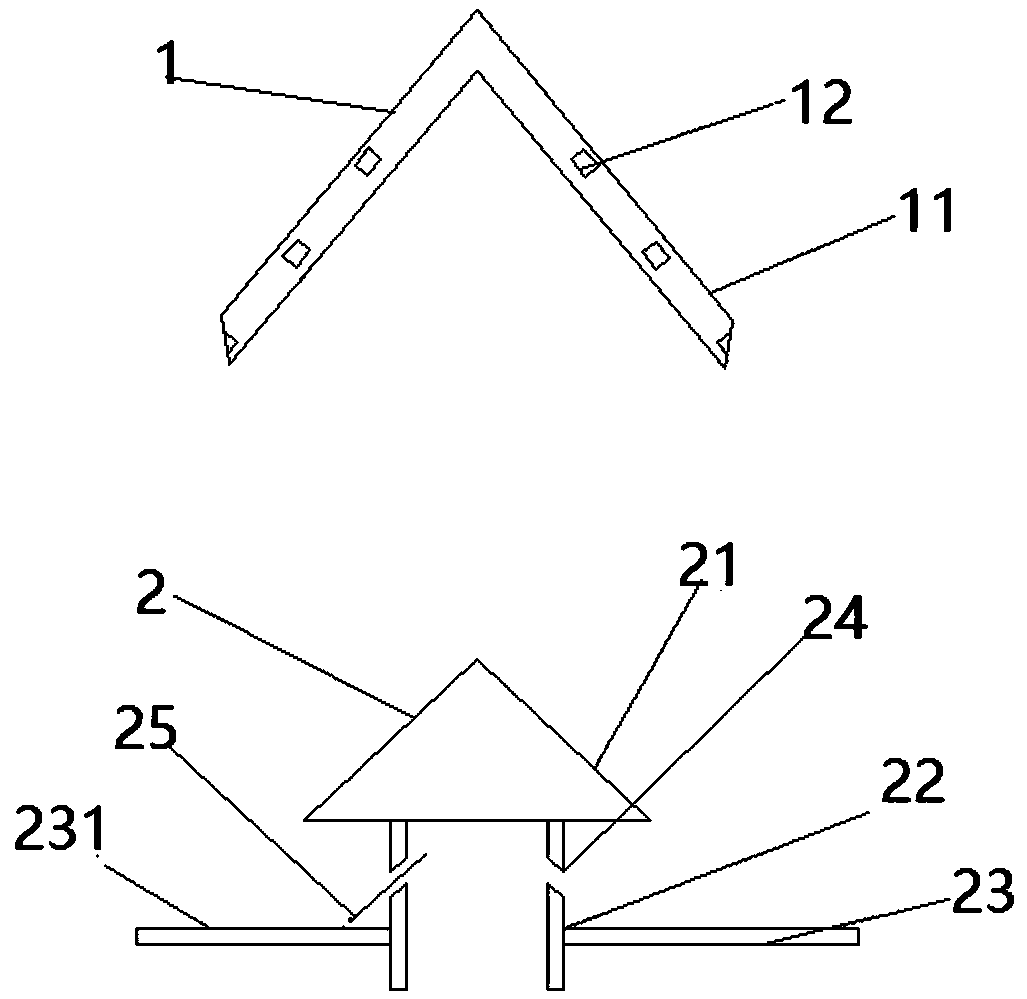

Embodiment 1

[0041] A gypsum calciner, the diameter of the first bulk material cap 11 of the feeding device 1 can be 1.2 times the diameter of the second bulk material cap 21 of the bottom blowing device 2, and the inclined multiple air holes 24 of the bottom blowing device The angle between the extension line 25 and the air uniform plate 23 can be 8°, and the surface roughness of the air uniform plate 23 of the bottom blowing device is 0.1.

Embodiment 2

[0043] A gypsum calciner, the diameter of the first bulk material cap 11 of the feeding device 1 can be 0.9 times the diameter of the second bulk material cap 21 of the bottom blowing device 2, and the inclined multiple air holes 24 of the bottom blowing device The angle between the extension line 25 and the air uniform plate 23 can be 45°, and the surface roughness of the air uniform plate 23 of the bottom blowing device is 0.5.

Embodiment 3

[0045] A gypsum calciner, the diameter of the first bulk material cap 11 of the feeding device 1 can be 0.8 times the diameter of the second bulk material cap 21 of the bottom blowing device 2, and the inclined multiple air holes 24 of the bottom blowing device The angle between the extension line 25 and the air uniform plate 23 can be 20°, and the surface roughness of the air uniform plate 23 of the bottom blowing device is 0.05.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com