Energy-saving and environment-friendly wet coke quenching tower

An energy-saving and environment-friendly quenching tower technology, applied in the field of coking, can solve the problems of large water consumption, serious water consumption, and large water mist particles in the quenching tower, and achieve high energy utilization, reduce coke quenching costs, and less pollution emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

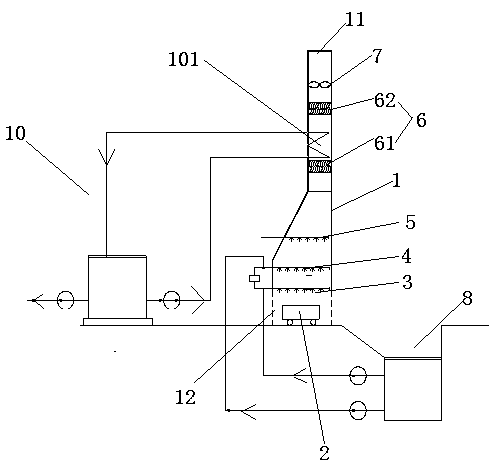

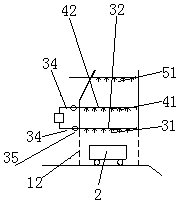

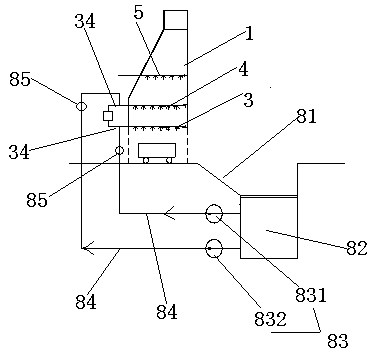

[0035] Such as Figure 1~4As shown, an energy-saving and environment-friendly wet quenching tower includes a tower body 1 fixedly installed on the ground. The upper end of the tower body 1 is provided with an exhaust port 11, and the side part of the lower end is provided with a hole that allows the coke quenching vehicle 2 to pass through and enter. The inlet 12 of the tower body 1 is arranged in sequence from bottom to top with a cooling spray assembly 3, a dedusting and demisting spray assembly 4, an atomizing and condensing assembly 5, a defogging assembly 6 and an induced draft fan 7. The tower body 1 is also connected with a waste heat utilization energy-saving assembly 10, and the waste heat utilization energy-saving assembly 10 includes a condenser 101 arranged inside the tower body 1 and located below the induce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com