Vacuum strobe frequency observation window

A technology of observation window and glass observation window, which is applied in the field of vacuum strobe observation window, can solve the problems that the operator cannot see clearly and blocks the viewer's sight, and achieves the effect of convenient observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with specific examples, but the embodiments of the present invention are not limited thereto.

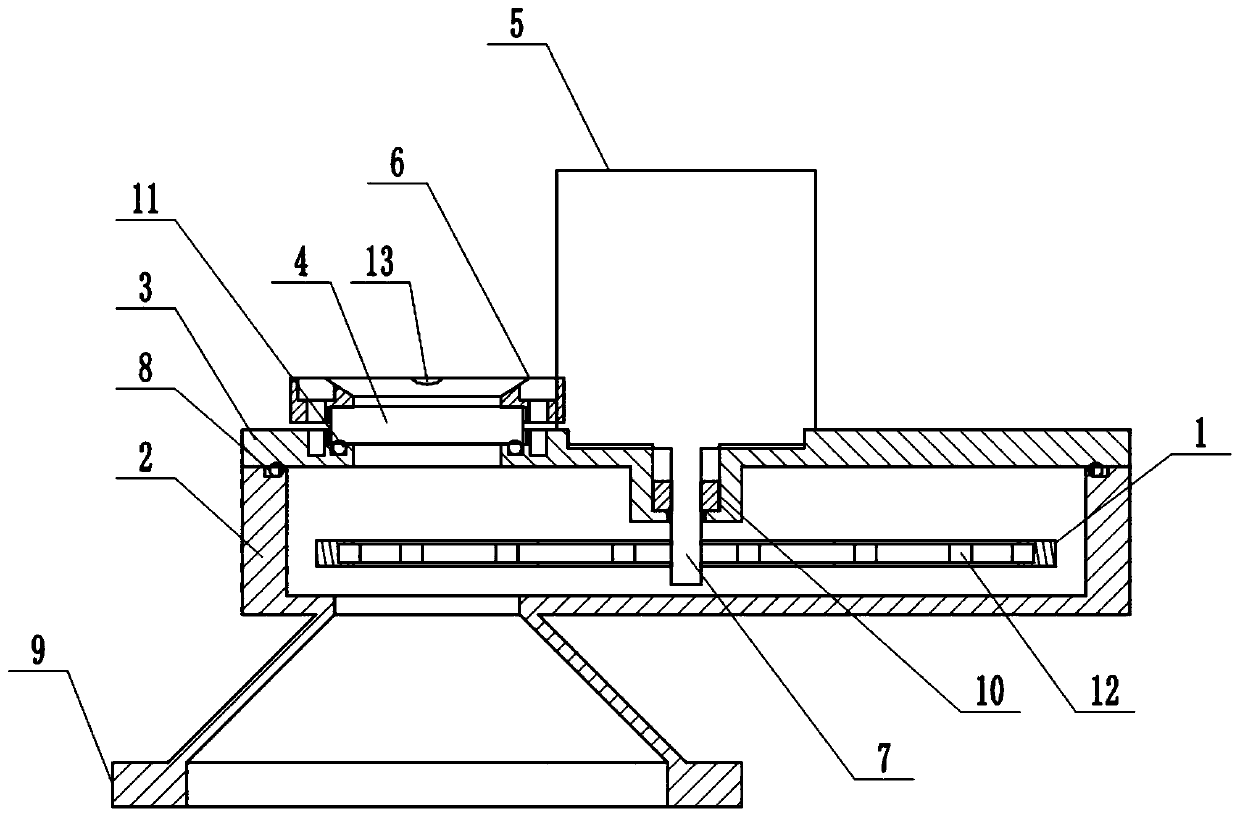

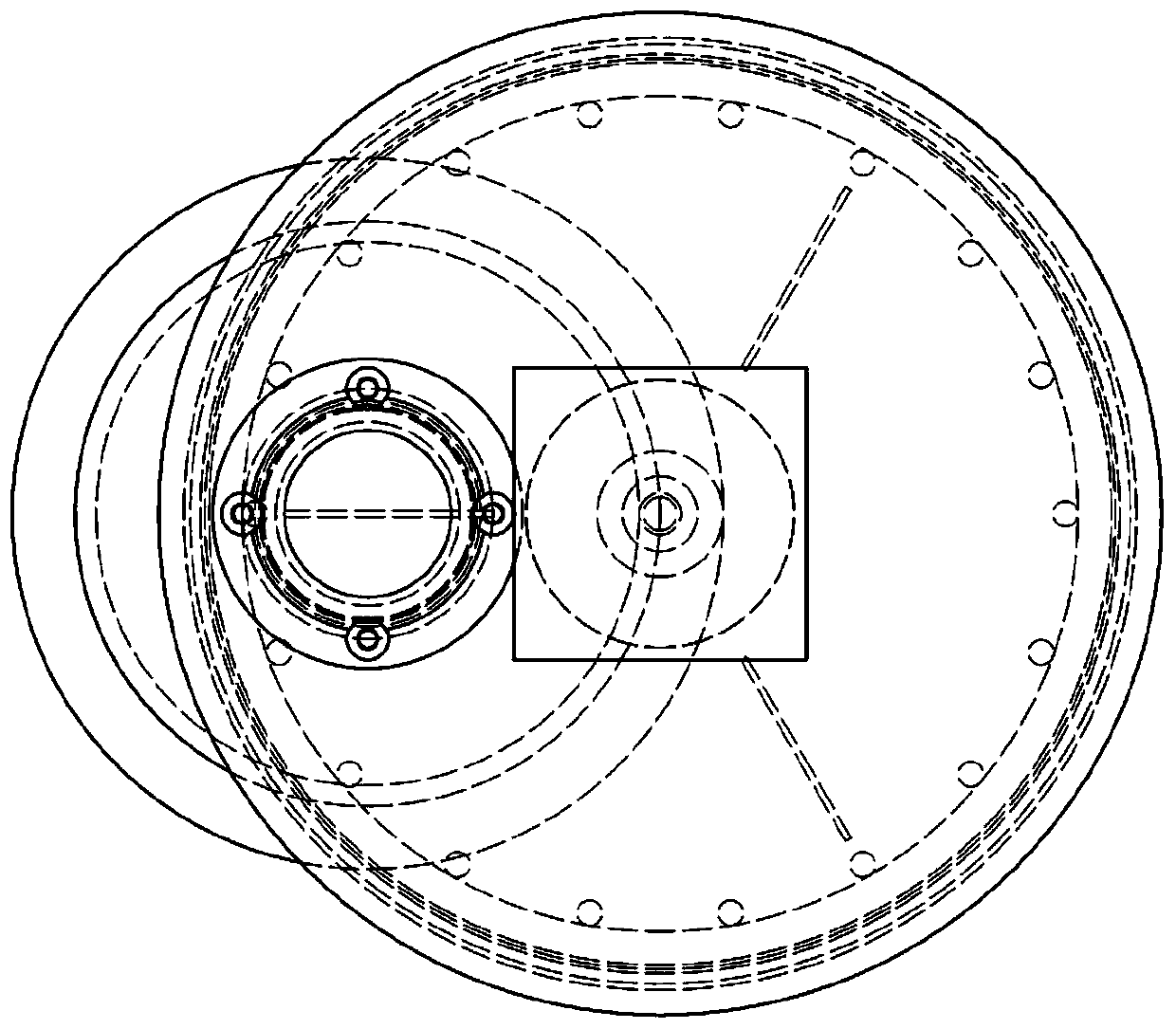

[0021] See also figure 1 , figure 2 and image 3 , the embodiment of the present invention provides a vacuum strobe observation window, including: a rotating disc 1, a housing 2, an upper cover 3, a glass observation window 4, and a motor 5; wherein,

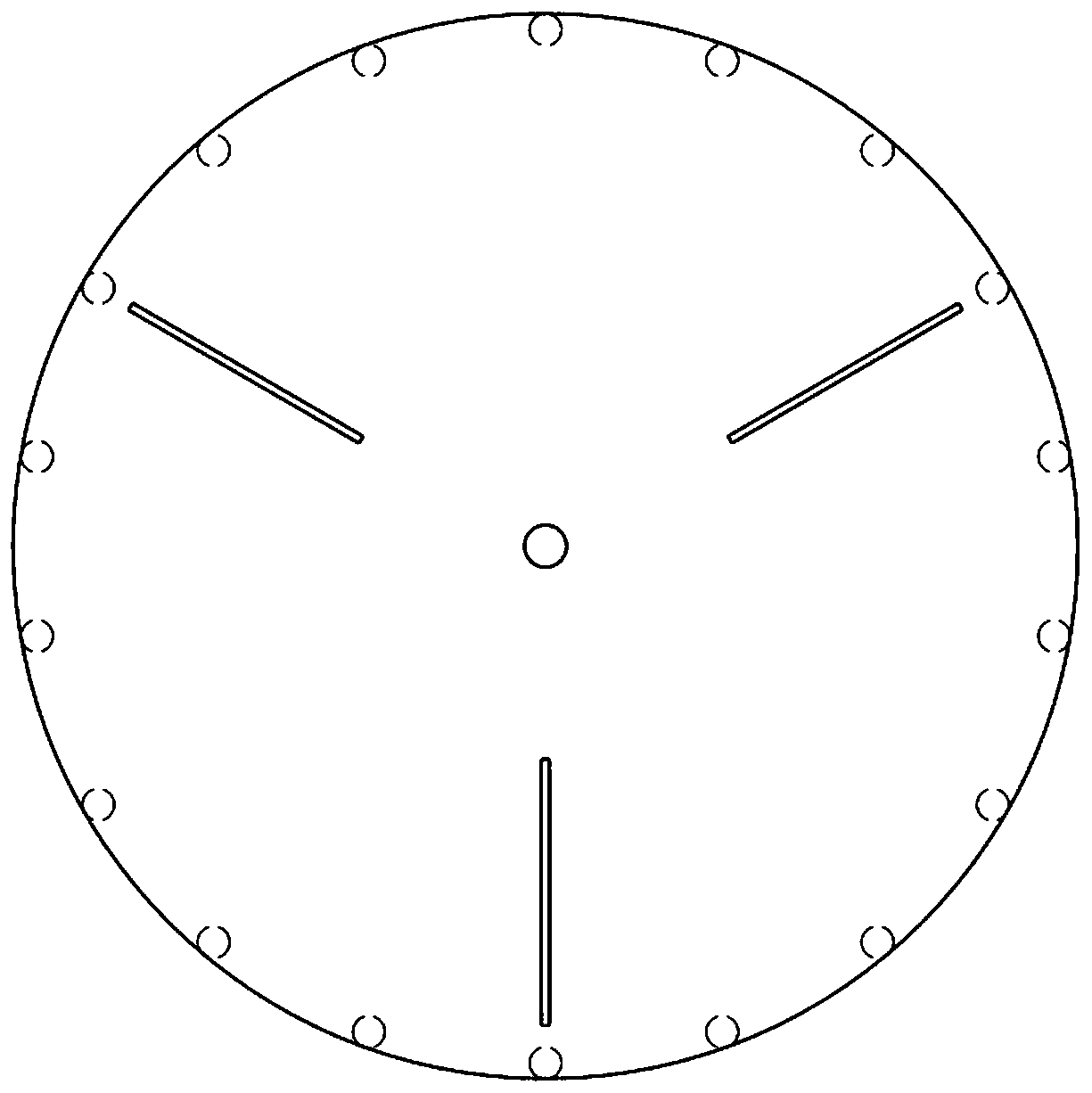

[0022] The rotating disk 1 is located in the housing 2 and is surrounded by two layers of disks, so that a cavity is formed between the upper and lower layers of disks, and the upper and lower layers of disks are centered on the center of the circle, and the center is symmetrically arranged with two The straight seam above the strip, and make the straight seams set on the upper and lower discs one-to-one.

[0023] Preferably, three straight slits are provided; the length of the straight slits is less than the radius of the rotating disc 1 , and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com